Engineering Solutions is a unified environment tailored for select engineering disciplines. It is built around best-in-class solver technology as well as using the advanced tool set of the HyperWorks desktop.

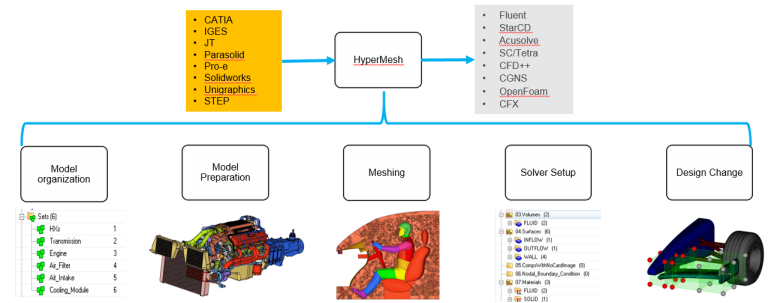

Engineering Solutions offers a wide range of tools enabling the user to perform CFD modeling in an efficient manner.

| • | Import interfaces for all major CAD tools (CATIA, ProE, UG,…) |

| • | Powerful geometry - FE based cleanup/generation capabilities |

| • | Several surface meshing algorithms for curvature dependent surface meshing with local refinement and user defined growth rate |

| • | Robust volume mesh generation, such as BL mesh, tet mesh, hybrid grids or hex-core meshing |

| • | Native export/import interfaces for all major CFD tools |

| • | Several surface meshing algorithms, such as BL mesh, tet mesh, curvature dependent surface meshing with local refinement and user defined growth rate |

| • | Robust volume mesh generation, such as hybrid grids or hex-core meshing |

| • | Native export/import interfaces for all major CFD tools |

| • | Case setup and solver launch for CFD solver AcuSolve |

| • | CFD post-processing in HyperView |

| • | Smooth integration of HyperStudy and AcuSolve to perform optimization studies |

|

The NVH user profile is a HyperWorks environment customized for automotive full vehicle NVH modeling and analysis needs. It includes a number of integrated components to help NVH users execute a typical full vehicle analysis process.

Benefits:

| 1. | Simulation of real-world events |

| a. | Directly simulate customer usage experience |

| b. | Drive physical prototype development |

| c. | Identify problems related to specific loadcase/response |

| d. | Understand cost and benefit |

| 2. | Physical root cause understanding |

| a. | Identify source-path-receiver clearly |

| b. | Most effective solutions often come from source reduction |

| c. | Understand noise/vibration energy transfer paths |

| d. | Identify most sensitive parts & cost effective solutions |

| e. | Validate CAE model through trend prediction |

| f. | Obtain force distribution for component level analysis and optimization |

| 3. | Ability to apply the entire NVH toolset |

| a. | Effective problem resolution requires using the right tools |

| b. | Low frequency – modal alignment and contribution analysis |

| c. | Mid frequency – transfer path, point mobility, and panel analysis |

| e. | Mass damper and tuned mass dampers |

| f. | Mastic or beads on panels |

|

The new Crash application in Engineering Solutions offers a tailored environment in HyperWorks that efficiently steers the Crash CAE specialist in CAE model building, starting from CAD geometry and finishing with a runnable solver deck in both solvers RADIOSS and LS-DYNA. A one-way transfer to HyperCrash to complete safety setup within HyperWorks is also available.

|

A new user profile has been added in 12.0.110. This profile is aimed to help to capture the aerospace model building process and tools needed for automation.

|

The Drop Test Manager is an automated solution that allows the user to either simulate a single drop test or a choice of multiple iterations with the aim of finding the sensitivity of process variables like initial orientation and drop height in a typical drop test by controlling the run parameters and conditions with ease.

|

HyperWorks Durability Director is a solver-neutral, process-oriented customization of HyperWorks that addresses many of the challenges associated with assessing the fatigue life of mechanical components. Durability Director manages the entire durability process from cascading measured loads, to predicting fatigue on individual components in the system.

|

Suspension Director (SD) is an industry specific solution that is integrated with MotionView and utilizes many aspects of HyperWorks to assist with the engineering of vehicle suspensions. SD contains several industry standard suspension topologies and analyses and is easily customizable. It utilizes state of the art assembly technology in MotionView and allows you to store & retrieve models using Library Manager. When using SD, all aspects of general MotionView are available to the user.

SD enables you to quickly add, solve and post-process a suspension model that is in the library. Or you can customize the library by adding additional suspensions, analyses or auto-entities to fit your engineering needs.

|

AcuSolve's dedicated Graphical User Interface, AcuConsole, contains a full set of options to help you build your CFD models quickly and efficiently. It provides full support for AcuSolve's features and can be used as an interactive tool or automated in a batch process. Intelligent default settings and an intuitive interface make learning the product quick and easy. AcuConsole's model set-up process is tightly tied to the water tight CAD model that is used to construct the simulation. All settings associated with boundary conditions, mesh controls, material properties, etc. are stored on the CAD faces and bodies such that these settings can be applied at any time during the pre-processing operation. Once the model has been meshed, all settings are inherited on the discretized model based on association with the geometry. This workflow provides powerful abstract modeling capabilities and enables rapid investigation of new designs. All settings are stored within the AcuConsole database, and investigating a new candidate design is as easy as importing the new CAD model. All settings are automatically re-applied based on the similarities between the geometric models.

|

The Virtual Wind Tunnel (VWT) is a vertical solution to perform external aerodynamic studies of vehicles, buildings, bicycles, or other objects in an efficient manner. Powered by Altair’s computational fluid dynamic (CFD) solver AcuSolve, transient and steady state studies can be performed accurately and in a short time frame. An intuitive user interface streamlines the process to define parameters for meshing as well as the CFD case setup. The definition of physical objects, like rotating wheels or radiators, includes intelligent automation to reduce the user interaction to a minimum. The Virtual Wind Tunnel comes with a fast and robust volume mesher and automatic report generation.

|