Composite Material |

|

|

|

|

|

Composite Material |

|

|

|

|

In RADIOSS the following material laws are used to describe composite material:

| • | LAW12 and LAW14 |

| • | LAW15 (recommended to use LAW25+/FAIL/CHANG) |

| • | LAW25 |

| • | LAW19 (For Fabric and with only /PROP/TYPE9) |

| • | LAW58 (For Fabric only with /PROP/TYPE16) |

Table 1: Composite material, property, failure model, and element type compatibility

|

Shell Element |

Brick Element |

Failure Model |

|---|---|---|---|

LAW12 |

|

/PROP/TYPE6 (SOL_ORTH) /PROP/TYPE21 (TSH_ORTH) /PROP/TYPE22 (TSH_COMP) |

/FAIL/HASHIN /FAIL/PUCK /FAIL/LAD_DAMA |

LAW14 |

|

/PROP/TYPE6 (SOL_ORTH) /PROP/TYPE21 (TSH_ORTH) /PROP/TYPE22 TSH_COMP) |

/FAIL/HASHIN /FAIL/PUCK /FAIL/LAD_DAMA |

LAW15 |

/PROP/TYPE9 (SH_ORTH) /PROP/TYPE10 (SH_ORTH) /PROP/TYPE11 (SH_SANDW) /PROP/TYPE17 (STACK) /PROP/TYPE19 (PLY) |

|

/FAIL/CHANG |

LAW25 |

/PROP/TYPE10 (SH_ORTH) /PROP/TYPE11 (SH_SANDW) /PROP/TYPE17 (STACK) /PROP/TYPE19 (PLY) /PROP/TYPE51 |

/PROP/TYPE6 (SOL_ORTH) /PROP/TYPE14 (SOLID) /PROP/TYPE20 (TSHELL) /PROP/TYPE21 (TSH_ORTH) /PROP/TYPE22 TSH_COMP) |

/FAIL/CHANG /FAIL/HASHIN /FAIL/PUCK /FAIL/LAD_DAMA |

LAW19 |

/PROP/TYPE9 (SH_ORTH) |

|

|

LAW58 |

/PROP/TYPE16 (SH_FABR) |

|

|

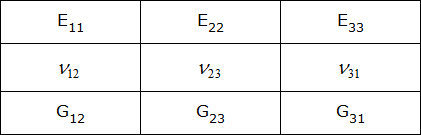

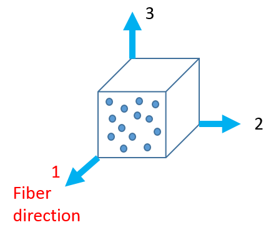

LAW12 and LAW14 describe orthotropic solid material which use the Tsai-WU formulation. The materials are 3D orthotropic-elastic, before the Tsai-Wu criterion is reached. LAW12 is a generalization and improvement of LAW14.

Both material laws require Young's modulus, shear modulus and Poisson ratio (9 parameters) to describe the material orthotropic in elastic phase.

![]()

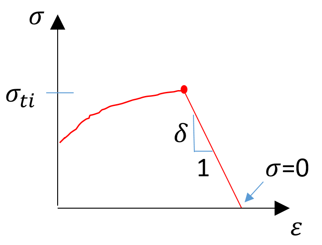

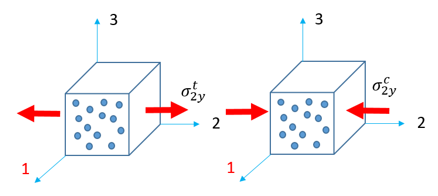

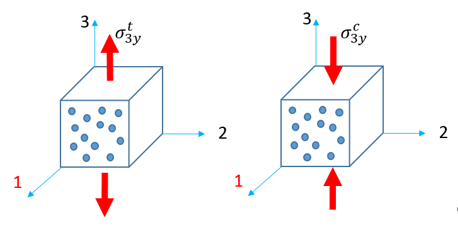

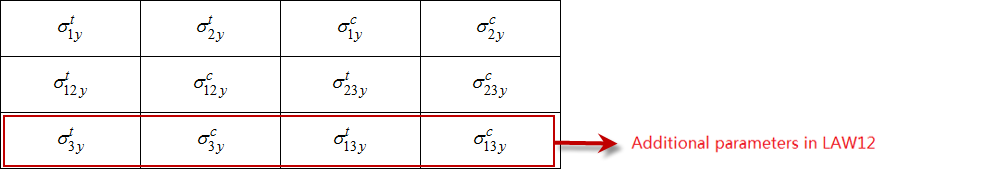

Stress limits ![]() (in tensile/compression) are requested for damage. These stress limits could be observed from a tensile test in 3 related directions.

(in tensile/compression) are requested for damage. These stress limits could be observed from a tensile test in 3 related directions.

Once stress limit is reached, then damage to material begins (stress reduced with damage parameter ![]() ). If Damage (

). If Damage (![]() ) reaches D=1, then stress is reduced to 0.

) reaches D=1, then stress is reduced to 0.

In LAW12 (3D_COMP), the Tsai-Wu yield criteria is:

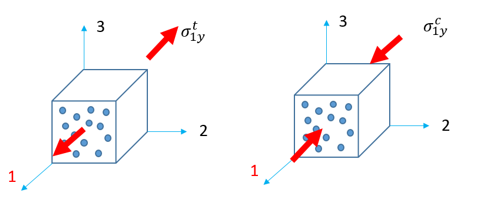

The 12 coefficients of the Tsai-Wu criterion could be determined using the yield stress from the following tests:

| • | Longitude tensile/compression (in direction 1): |

![]()

| • | Transverse tensile/compression (in direction 2) |

![]()

| • | Transverse tensile/compression (in direction 3) |

Then the interaction coefficients can be calculated as:

![]()

![]()

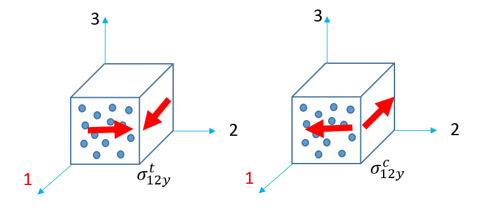

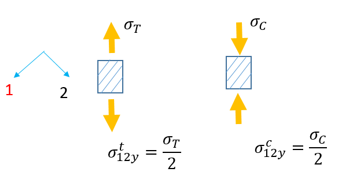

| • | Shear in plane 1-2 test: |

![]() and

and ![]() can result from the sample tests below:

can result from the sample tests below:

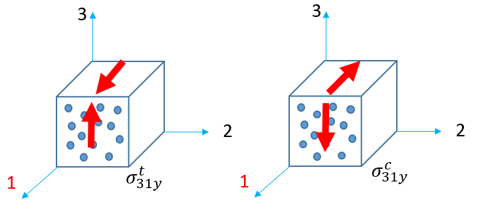

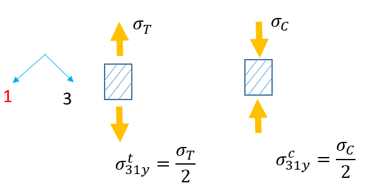

| • | Shear in plane 1-3 |

![]() and

and ![]() can result from the sample tests below:

can result from the sample tests below:

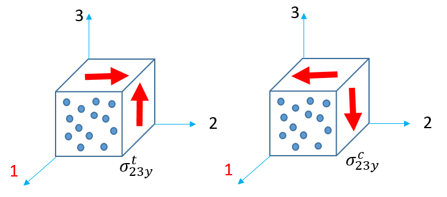

| • | Shear in plane 2-3 |

The parameters shown below in LAW12 and LAW14 are requested to calculate the Tsai-Wu criteria:

The yield surface for Tsai-Wu is ![]() . As long as

. As long as ![]() , the material is in the elastic phase. Once

, the material is in the elastic phase. Once ![]() , the yield surface is exceeded and the material is in nonlinear phase.

, the yield surface is exceeded and the material is in nonlinear phase.

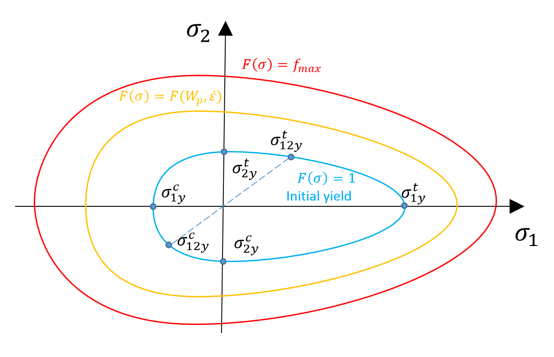

In these two material laws, the following factors could also be considered for yield surface.

| • | Plastic work |

| • | Strain rate |

Then the yield surface will be ![]() .

.

| • | Material will be in elastic phase, if |

| • | Material will be in nonlinear phase, if |

This yield surface ![]() will be limited with

will be limited with ![]() (

(![]() ). Where

). Where ![]() is the maximum value of the Tsai-Wu criterion limit.

is the maximum value of the Tsai-Wu criterion limit.

Depending on parameter B, n, c and ![]() , the yield surface is between 1 and

, the yield surface is between 1 and ![]() .

.

Fig1: Tsai-Wu yield criteria in 1-2 plane

LAW25 is the most commonly used composite material in RADIOSS. It can be used with shell and solid elements. The two formulations available in LAW25 are the Tsai-Wu and CRASURV formulations.

In the elastic phase, Young's modulus (3 parameters), shear modulus (3 parameters) and one parameter for Poisson ratio are required to describe the orthotropic material.

| 1. | The Tsai-Wu yield surface in LAW25 is defined with 6 coefficient as follows: |

|

Iform=0: Tsai-Wu |

Iform=1: CRASURV |

Tsai-Wu yield surface |

|

|

| 2. | These 6 coefficients could be determined with yield stress from these tests: |

Iform=0: Tsai-Wu |

Iform=1: CRASURV |

||

Tensile/compression tests |

Longitudinal tensile/compression tests (in direction 1 which is fiber direction):

|

|

In tension:

In compression:

Here |

Transverse tensile/compression tests (in direction 2)

|

|

In tension:

In compression:

|

|

Shear tests |

Shear in plane 1-2

|

|

In shear:

|

Interaction coefficients |

The default reduction factor, |

The default reduction factor, |

|

| 3. | Note that the relative plastic work |

|

Iform=0: Tsai-Wu |

Iform=1: CRASURV |

Yield surface limit |

With Here |

|

Material in elastic phase, if Material in nonlinear phase, if The yield stress limit |

Material in elastic phase, if Material in nonlinear phase, if

|

| 4. | In LAW25 (Tsai-Wu and CRASURV) damage is a function of the total strain and the maximum damage factor. |

If the total strain ![]() or out of plane strain

or out of plane strain ![]() , then the material is softened using the following method:

, then the material is softened using the following method:

![]() with i=1,2,3

with i=1,2,3

Where, di is the damage factor and is defined as:

with i=1,2

with i=1,2

in direction 3 (delamination)

in direction 3 (delamination)

| • | If the total strain is between |

| • | Damage could be in elastic phase or in plastic phase. It depends on which phase |

| • | Element deletion is controlled by Ioff. Select a different Ioff option to control the criteria of element deletion. For additional information, refer to Ioff in LAW25 in the Reference Guide. |

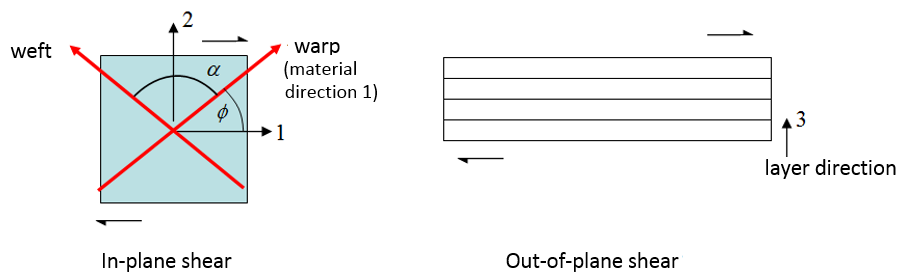

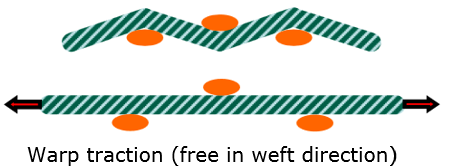

RADIOSS has two material laws for modeling fabrics LAW19 and LAW58. LAW19 is an elastic orthotropic material and must be used with /PROP/TYPE9. LAW58 is hyperelastic anisotropic fabric material and must be used with /PROP/TYPE16. Coupling between warp and weft directions could be defined in this material law to reproduce physical interaction between fibers. Both material laws are often used for airbag modeling.

In LAW58, two methods are provided to define the stress-strain behavior.

| • | Nonlinear function (fct_IDi) curve to define the warp, weft and shear behavior |

| • | Young's modulus, soften coefficient B, straightening strain Si and fiber bending modulus reduction factor Flexi |

In warp and weft direction:

![]() if

if  (straightening phase)

(straightening phase)

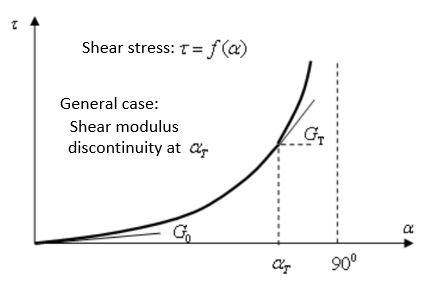

For in-plane shear in initial state, use G0. Once ![]() (angle between wrap and weft) reaches

(angle between wrap and weft) reaches ![]() (shear lock angle), then use GT to describe the strengthening.

(shear lock angle), then use GT to describe the strengthening.

![]() if

if ![]()

For out-of-plane shear stress-strain is described with Gsh.

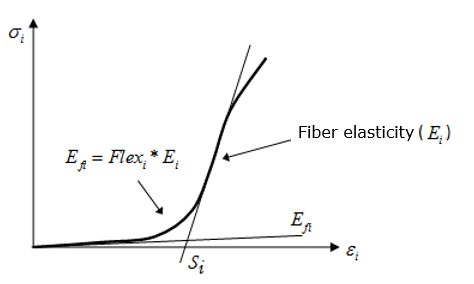

For fiber elasticity, if you tensile the fiber, due to the fiber not tighten yet and show very soft.

In LAW58, use Flexi to describe this behavior:

![]()

Once the strengthening strain Si is reached, then normal fiber elasticity Ei could be used.