This example demonstrates how size optimization can be used.

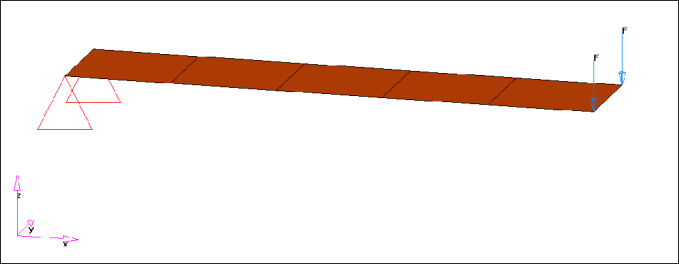

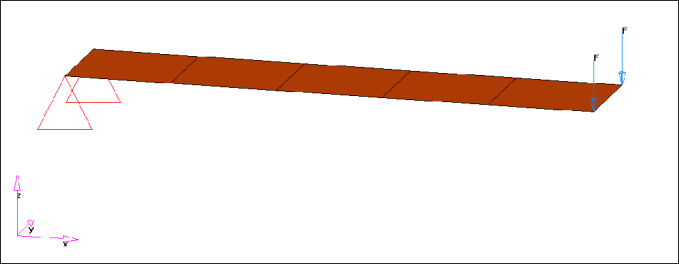

For the cantilever beam below, a thickness distribution is sought that minimizes the structural mass and allows a limited vertical deflection of the loading end. The displacement is limited to 2.0mm.

Structural Model

In this example, the thickness for each element is varied. Therefore, five variables are defined in the analysis deck. The initial thickness of all elements is 2mm. All thickness variables have a lower bound of 1mm and an upper bound of 3mm.

The optimization problem, objective and constraint functions, is defined in the same manner as for the other types of structural optimization. OptiStruct then goes through an iteration process to solve the optimization problem. OptiStruct converged after 3 iterations. The table below shows the optimization results of the cantilever beam, which met the constraints and minimizes the mass (decrease of 6.6%).

|

Element 1

|

Element 2

|

Element 3

|

Element 4

|

Element 5

|

Disp

|

Volume

|

Initial

|

2.0mm

|

2.0mm

|

2.0mm

|

2.0mm

|

2.0mm

|

2.5mm

|

400.00mm3

|

Final

|

2.6mm

|

2.3mm

|

1.9mm

|

1.5mm

|

1.0mm

|

2.0mm

|

373.204mm3

|

The input file can be found in <install_directory>/demos/hwsolvers/optistruct/size1.fem.