This tutorial demonstrates how to perform a topology optimization on an automotive control arm with the simultaneous application of symmetry and draw direction constraints.

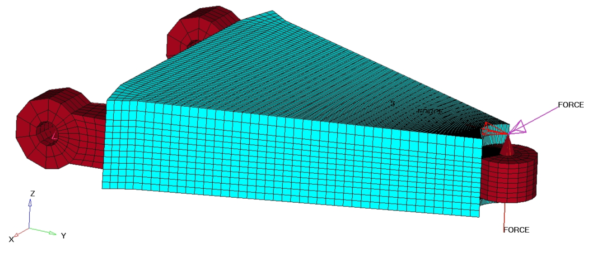

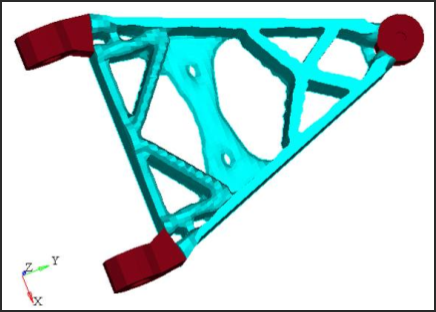

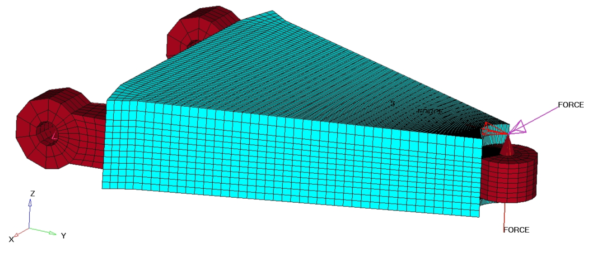

This tutorial uses the same optimization problem considered in Design Concept for an Automotive Control Arm (OS-2010), except that a refined mesh will be used in order to better capture the effect of applying symmetric and draw manufacturing constraints simultaneously. The finite element mesh of the structural model containing the designable (blue) and the non-designable (red) regions, along with the loads and constraints applied, is shown in the following figure.

The optimization problem is stated as:

Objective:

|

Minimize volume.

|

Constraints:

|

SUBCASE 1:

|

The resultant displacement of the point where loading is applied must be less than 0.05 mm.

|

SUBCASE 2:

|

The resultant displacement of the point where loading is applied must be less than 0.02 mm.

|

SUBCASE 3:

|

The resultant displacement of the point where loading is applied must be less than 0.04 mm.

|

Design variables:

|

Element density.

|

This tutorial covers the following exercises:

| • | Defining the symmetry and draw direction control parameters for optimization |

| • | Post-processing the results in HyperView |

Exercise

Step 1: Launch HyperMesh, Set the User Profile, and Import a File

| 1. | Launch HyperMesh Desktop. |

| 2. | Choose OptiStruct in the User Profiles dialog and click OK. This loads the user profile. It includes the appropriate template, macro menu, and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct. |

The User Profiles GUI can also be accessed from the Preferences menu on the toolbar.

| 3. | Click the Import Solver Deck icon  and select the carm_draw_symm.fem file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. and select the carm_draw_symm.fem file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. |

Defining the Symmetry and Draw Direction Control Parameters for Optimization

Step 2: Define the Symmetry and Draw Direction Manufacturing Constraints

| 1. | From Analysis page, enter the optimization panel. |

| 2. | Click topology to enter the panel. |

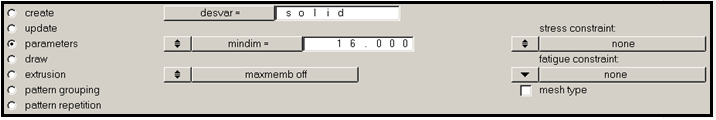

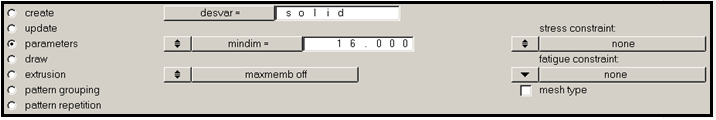

| 3. | Click review and select the desvar solid. |

| 4. | Select the parameters subpanel and define a minimum member size = 16.0 mm. |

This forces the diameter or thickness of any structural member to be higher than 16 mm; if this is not user-set, OptiStruct automatically selects a minimum member size based on the average mesh size (if a manufacturing constraint is selected).

| 5. | Click update to confirm the minimum member size set up. |

| 6. | Select the draw subpanel to set up the draw direction. |

| 7. | Set the selector under draw type: to single. |

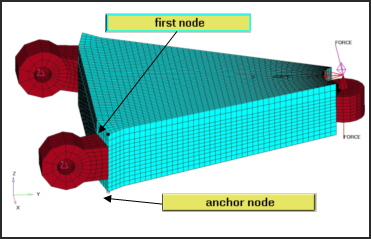

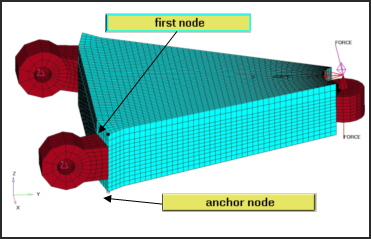

| 8. | Select the anchor node and the first node as shown below. Together, these two nodes define a vector in the positive Z direction. This defines that the die draw direction is along the positive Z direction. |

| 9. | Select obstacle: as the nondesign property. |

| 10. | Select the pattern grouping subpanel to define the symmetry constraint and toggle the pattern type: to 1-pln sym. |

The symmetry constraints in topology optimization lead to symmetric designs for solid models, regardless of the initial mesh, boundary conditions or loads. In this case, the 1-pln sym option enforces symmetry across a defined plane. A symmetric mesh is not required, as OptiStruct creates variables that are nearly identical across the plane(s) of symmetry. The plane of symmetry is defined by specifying the anchor and the first nodes. The plane of symmetry will then be perpendicular to the vector from the anchor node to the first node, and pass through the anchor node.

| 11. | Click anchor node, input the node id= 1, and press ENTER. |

This selects the node with the ID of 1.

| 12. | Click first node, input the node id= 2 and press ENTER. This selects the node with the ID of 2. |

| 13. | Click update to update the design variables. |

Together, these two nodes define a vector in the negative Z direction. Hence, the symmetry plane is defined as the plane perpendicular to the Z-axis (which is the same as the Y-Z plane), and passing through the anchor node.

This completes the definition of the symmetry constraint.

| 14. | Click return twice to go back to the Analysis page. |

Step 3: Run the Optimization Problem

This tutorial problem takes nearly one hour to run.

| 1. | From the Analysis page, enter the OptiStruct panel. |

| 2. | Click save as, enter carm_draw_symm_complete.fem as the file name, and click Save. |

| 3. | Set the export options: toggle to all. |

| 4. | Click the run options: switch and select optimization. |

| 5. | Make sure the memory options: toggle is set to 2000. |

| 6. | Leave the options: field blank. |

| 7. | Click OptiStruct to run the optimization. |

| 8. | Close the HyperWorks Solver View dialog when Processing complete appears. |

OptiStruct reports error messages (if any exist). The file carm_draw_symm_complete.out can be opened in a text editor to find details regarding any errors. This file is written to the same directory as the .fem file.

Post-processing Results with HyperView

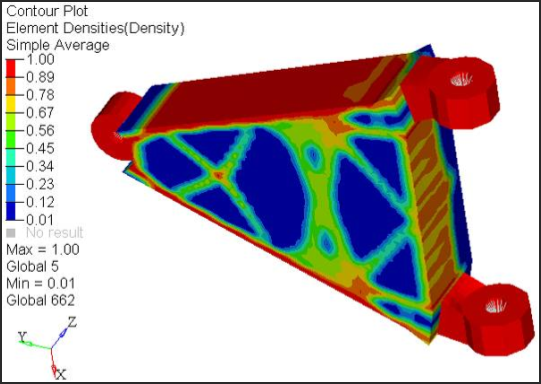

Step 4: Review Contour Plot of the Density Results

Element density results are output to the carm_draw_symm_complete_des.h3d file from OptiStruct for all iterations. In addition, displacement and stress results are output by default into carm_draw_symm_compelte_s#.h3d files for each subcase for the first and last iterations; where # specified the subcase ID. This section describes how to view those results in HyperView.

| 1. | Click the HyperView button in the panel to view the results. |

HyperView is launched and the results are loaded. A message window appears to inform about the successful loading of the model and result files into HyperView. Notice that all three .h3d files get loaded, each in a different page of HyperView.

| 2. | Click Close to close the message window. |

It is helpful to view the deformed shape of a model to determine if the boundary conditions are defined correctly, and also to find out if the model is deforming as expected. The analysis results are available in pages 2, 3, and 4. The optimization iteration results (Element Densities) are loaded in the first page.

| 3. | Click the Previous Page icon  until the name of the page is displayed as Design History, indicating that the results correspond to optimization iterations. until the name of the page is displayed as Design History, indicating that the results correspond to optimization iterations. |

| 4. | Enter the Contour panel by clicking the icon on the toolbar. |

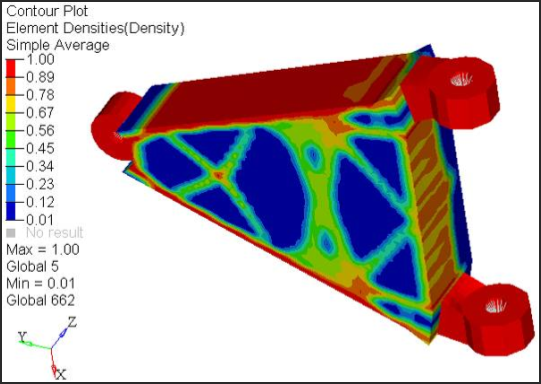

Note the Result type: is Element Densities [s]; this should be the only results type in the “file_name”_des.h3d file. The second drop-down list shows Density.

| 5. | In the Averaging method: field, select Simple. |

| 6. | Click Apply to display the density contour. |

Note the contour is all blue because your results are on the first design step or Iteration 0.

| 7. | Select the last iteration listed in the Results browser. |

Each element of the model is assigned a legend color, indicating the density of each element for the selected iteration.

Step 5: View an Iso Value Plot on Top of the Element Densities Contour

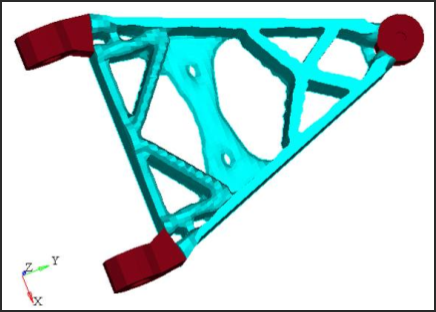

This plot provides the information about the element density. Iso Value retains all of the elements at and above a certain density threshold. Pick the density threshold providing the structure that suits your needs.

| 1. | From Graphics menu, click Iso, and select Element Densities as the Result type. |

| 2. | Set the Current Value: to 0.2. |

An iso value plot is displayed in the graphics window. The parts of the model with densities greater than the specified value of 0.2 are shown in the figure below.

Iso value plot of element densities

Have most of your elements converged to a density close to 1 or 0?

If there are many elements with intermediate densities, the DISCRETE parameter may need to be adjusted. The DISCRETE parameter (set in the opti control panel on the optimization panel) can be used to push elements with intermediate densities toward 1 or 0, so that a more discrete structure is given.

In this model, refining the mesh should provide a more discrete solution; however, for the purposes of this tutorial, the current mesh and results are sufficient.

Regions that need reinforcement tend towards a density of 1.0. Areas that do not need reinforcement tend towards a density of 0.0.

Is the max= field showing 1.0e+00?

In this case, it is.

If it is not, the optimization has not progressed far enough. Allow more iterations and/or decrease the OBJTOL parameter (also set in the opti control panel).

If adjusting the discrete parameter, refining the mesh, and/or decreasing the objective tolerance does not yield a more discrete solution (none of the elements progress to a density value of 1.0), review the set up of the optimization problem. Some of the defined constraints may not be attainable for the given objective function (or vice versa).

| 4. | Move the slider below Current value: to change the density threshold. |

The iso value appears in the graphics window update interactively when scrolling to a new value. Use this tool to get a better look at the material layout and the load paths from OptiStruct.

| 5. | From the File menu, select Exit to quit HyperView. |

Review

Has the volume been minimized for the given constraints?

Have the displacement constraints been met?

See Also:

OptiStruct Tutorials