In this tutorial, an existing finite element model of a bracket is used to demonstrate how to perform direct transient dynamic analysis using OptiStruct. HyperGraph is used to post-process the deformation characteristics of the bracket under the transient dynamic loads.

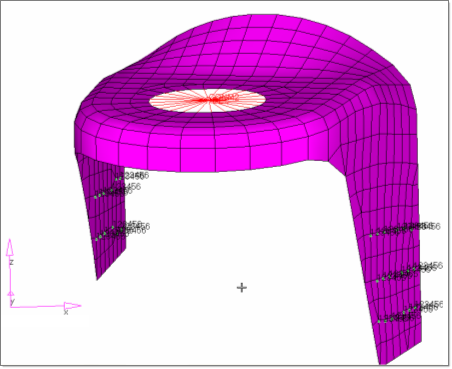

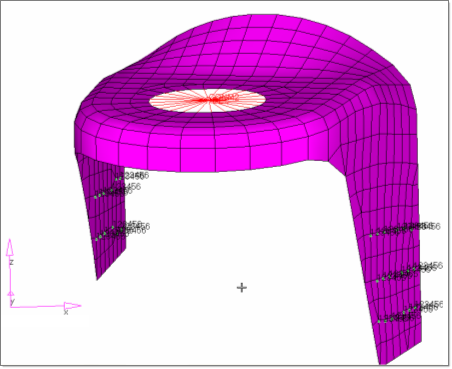

Finite element model of the bracket

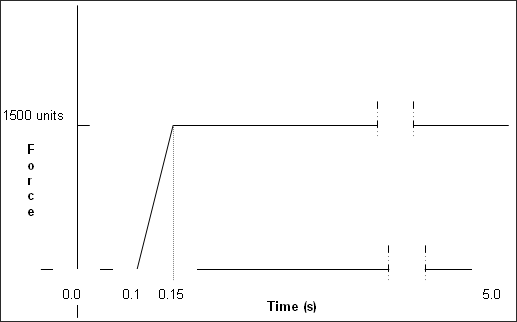

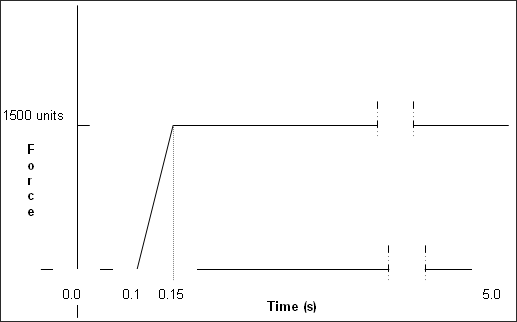

The bracket is constrained at the bottom of the two legs. Transient dynamic loads are to be applied at the grid points of the top, flat surface of the bracket around the hole in the negative z direction. The time history of the loading is shown in the next figure. The direct transient analysis is run for a total time of 4 seconds with the time being divided into 800 increments (that is time step is 0.005). Structural damping has been considered for the model. A concentrated mass element is defined at the center of the spider and z displacements are monitored at the concentrated mass at the center of this hole.

Time history of applied loading

This tutorial uses the following exercises to set up a direct transient dynamic analysis:

| • | Create the time dependent dynamic load or the variation of load vs time |

| • | Create the time step for transient analysis |

| • | Create the grid point forces on the top flat surface of the bracket |

| • | Create the transient response dynamic excitation |

| • | Create the subcase to include all the necessary loads as defined above |

| • | Specify structural damping and output requests |

| • | Run direct transient dynamic analysis |

| • | Post-process results using Altair HyperGraph |

Exercise

Step 1: Launch HyperMesh and set the OptiStruct User Profile

| 1. | Launch HyperMesh. The User Profiles dialog appears. |

| 2. | Select OptiStruct and click OK. This loads the user profile. It includes the appropriate template, macro menu, and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct. |

Step 2: Retrieve the file

| 1. | Click File > Open. An Open Model browser window opens. |

| Note: | If HyperMesh Desktop was launched, use: File > Open > Model. |

|

| 2. | Select the bracket_transient.hm file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. |

Setting up the Transient Dynamic Analysis Problem (Steps 3 - 9)

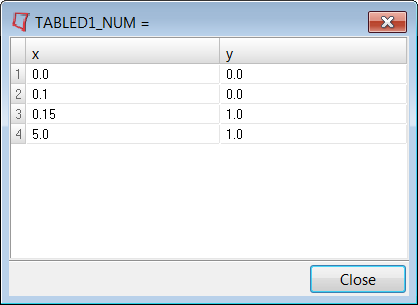

Step 3: Create a TABLED1 (Table to define time dependent dynamic load)

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter tabled1. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select TABLED1 from the drop-down menu. |

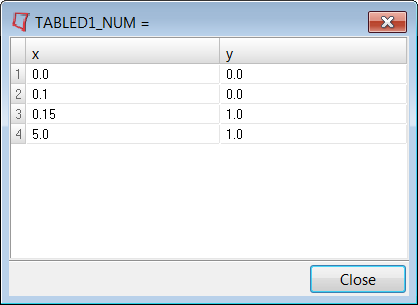

| 5. | For TABLED1_NUM, enter a value of 4 and press enter. |

| 6. | Click the table icon  below TABLED1_NUM and enter the values in the pop-out window, as shown in the figure below. below TABLED1_NUM and enter the values in the pop-out window, as shown in the figure below. |

| 7. | Click Close. The load collector TABLED1 that defines the time history of the loading has been created. |

Step 4: Create a TSTEP (Transient time step to define the time step intervals at which solution is generated and output)

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select TSTEP on the pop-up menu. |

| 5. | For TSTEP_NUM, enter 1 and press ENTER. |

| 6. | For N, enter the number of time steps as 800. |

| 7. | For DT, enter the time increment of 0.005. The total time applied to the load is: 800 x 0.005 = 4 seconds. |

NO has a default value of 1.0. This is the time step at which output is requested.

Step 5: Create a DAREA to define forces on the top surface of the bracket

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select None. |

| 5. | Click BCs > Create > Constraints to open the Constraints panel. |

| 7. | Two sets are displayed, select force and click select. The nodes that belong to the set force get selected. |

| 8. | Uncheck all degrees of freedom (dof); except dof3 by clicking the box next to each, indicating that dof3 is the only active degree of freedom. |

| 9. | For dof3, enter a value of -1500. |

| 10. | For load types=, select DAREA. |

| 11. | Click create. This creates a force of 1500 units applied to the selected nodes in the negative z direction. |

| 12. | Click return to go back to the main menu. |

Step 6: Create a TLOAD1 (the transient dynamic response excitation)

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter tload1. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select TLOAD1 from the drop-down list. |

| 5. | For EXCITEID , click Unspecified > Loadcol. |

| 6. | In the Select Loadcol dialog, select darea from the list of load collectors (created in the last section to define the forces on the top surface of the bracket). |

| 7. | Click OK to complete the selection. |

| 8. | Similarly select the tabled1 load collector for the TID field (to define the time history of the loading). |

The type of excitation can be an applied load (force or moment), an enforced displacement, velocity, or acceleration. The field [TYPE] in the TLOAD1 card image defines the type of load. The type is set to applied load by default.

Step 7: Create a Load Step to perform Direct Transient Analysis

| 1. | In the Model browser, right-click and select Create > Load Step. |

| 2. | For Name, enter transient. |

| 3. | For Analysis type, select Transient (direct) from the drop-down menu. |

| 4. | For SPC, select spc from the Select Loadcol pop-out window. |

| 5. | For DLOAD, select tload1 from the Select Loadcol pop-out window. |

| 6. | Activate TSTEP(TIME) and select the load collector tstep created previously. A subcase is created that specifies the loads and boundary conditions for direct transient dynamic analysis. |

Step 8: Create Damping parameters for transient dynamic analysis

| 1. | Click Setup > Create > Control Cards to enter the Control Cards panel. |

| 2. | Click next to see more cards. |

| 3. | Click PARAM to define parameter cards. |

| 4. | Scroll down to activate G, click on G_V1, and enter 0.2. |

This parameter specifies the uniform structural damping coefficient for the direct transient dynamic analysis.

| 5. | Scroll down to activate W3, click on W3_V1, enter 300. |

This parameter is used in transient analysis to convert structural damping to equivalent viscous damping.

Step 9: Create Output requests for Transient Dynamic Analysis

| 1. | Click GLOBAL_OUTPUT_REQUESTS and select DISPLACEMENT and leave the space beneath FORMAT blank. |

| 2. | For FORM(1), select BOTH. |

| 3. | For OPTION(1), select SID. A yellow button labeled SID appears. |

| 4. | Double-click on SID and select center. |

| 5. | Select the option for center. |

This set represents the node at the center of the spider attached to the mass element that is node 395.

| 8. | Under number_of_outputs =, enter 2. |

| 9. | For KEYWORD, select H3D and HGTRANS. |

| 10. | For FREQ, select ALL for both. |

| 11. | Click return twice to exit from the Control Cards panel. |

Submit the Job

Step 10: Save the database

| 1. | Click File > Save as > Model to set the directory in which to save the file. |

| 2. | In File name:, enter bracket_transient_direct.hm. |

Step 11: Running direct transient dynamic analysis

| 1. | From the Analysis page, click OptiStruct. |

| 2. | Click save as. A Save As browser window opens. |

| 3. | Select the directory where you would like to write the file and enter the name bracket_transient_direct.fem in the File name: field. |

The name and location of the bracket_transient_direct.fem file displays in the input file: field.

| 5. | Set the export options: toggle to all. |

| 6. | Set the run options: togle to analysis. |

| 7. | Set the memory options: toggle to memory default. |

| 8. | Click OptiStruct. This launches the OptiStruct job. |

If the job was successful, new results files can be seen in the directory where the OptiStruct model file was written. The bracket_transient_direct.out file is a good place to look for error messages that will help to debug the input deck if any errors are present.

The default files written to the directory are:

bracket_transient_direct.html

|

HTML report of the analysis, giving a summary of the problem formulation and the results.

|

bracket_transient_direct.out

|

OptiStruct output file containing specific information on the file setup, the setup of the problem, estimates for the amount of RAM and disk space required for the run and compute time information. Review this file for warnings and errors that are flagged from processing the bracket_transient_direct.fem file.

|

bracket_transient_direct.h3d

|

HyperView binary results file

|

bracket_transient_direct_tran.mvw

|

HyperView session file. This file is only created when transient analysis is performed. This file automatically creates plots for the displacement, velocity and acceleration results contained in the file.

|

bracket_transient_direct.stat

|

Summary of analysis process, providing CPU information for each step during analysis process.

|

Review the Results using HyperGraph

Step 12: Post-process displacement results of node 395

| 1. | From the OptiStruct panel, click HyperView to launch HyperView. |

| 2. | Click File > Open > Session. |

| 3. | Select the HyperView session file bracket_transient_direct_tran.mvw from the directory in which the input file was run. The following prompt appears: |

| 4. | Click Yes to close the message window. This file automatically creates plots for the displacement results contained in the file. |

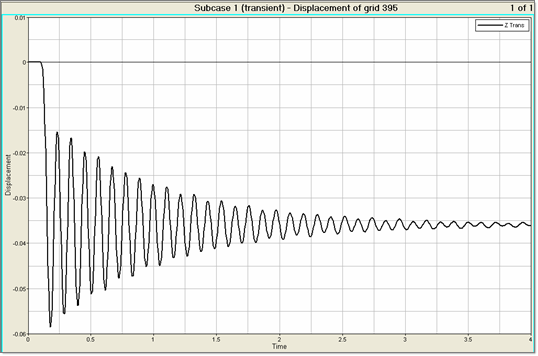

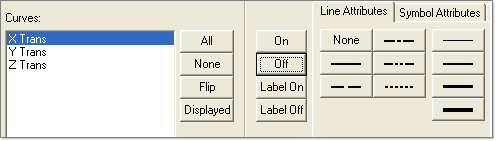

Since the loading is applied only in the z-direction, you are interested in the z-displacement time history of node 395.

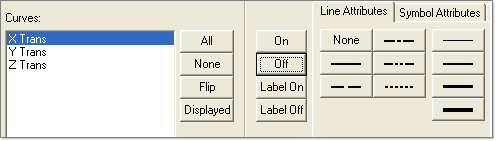

| 5. | Click on the Curve Attributes toolbar icon  and turn off the curves X Trans and Y Trans. This can be done by selecting the individual curves (X Trans and Y Trans) and then by clicking the line attributes Off, as shown below: and turn off the curves X Trans and Y Trans. This can be done by selecting the individual curves (X Trans and Y Trans) and then by clicking the line attributes Off, as shown below: |

| 6. | Click  to fit the y-axis (that is Z displacement) of node 395 in the GUI. to fit the y-axis (that is Z displacement) of node 395 in the GUI. |

| 7. | You can change the color and/or line attributes of the curve if you wish to. |

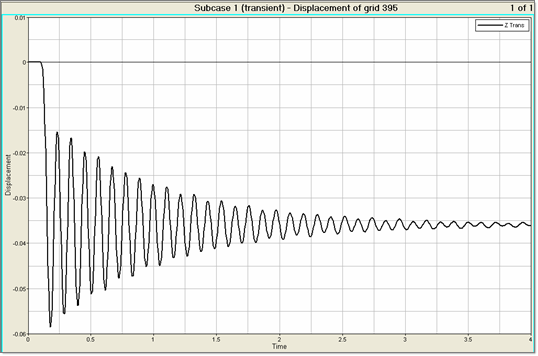

Z-displacement time history of the concentrated mass at center of spider for direct transient dynamic analysis

As can be observed from the above image, the displacements of node 395 are in the negative z-direction as the loading is in the –z direction too. The displacements eventually damp out due to the structural damping present in the model.

See Also:

OptiStruct Tutorials