Subcase Specific Modeling |

|

|

|

|

|

Subcase Specific Modeling |

|

|

|

|

Subcase specific modeling in OptiStruct allows you to analyze multiple structures in a single solver run. The structures can be completely independent; can represent different regions of the same model, or different assemblies sharing common parts. Subcase specific modeling is also known as submodeling. In a traditional modeling scenario without submodeling capabilities, the entire model will be solved for each solver run, regardless of the boundary conditions and multiple models will have to be created to solve structures with variable sections. Submodeling allows specific sections of the model to be solved independently without affecting the rest of the structure.

There are various advantages to subcase specific modeling for both analysis and optimization. The primary motivation for submodeling is the ability to solve independent structures with common parts. For example, in the case of a pickup truck, various cabin shapes can be solved for, by allowing the bed and the chassis to remain unchanged. This is accomplished by assigning elements belonging to different cabin types to different sets. The constant chassis and bed can be a defined as another element set. These element sets can now be combined to allow various structural submodels to be modeled without having to repeat the common parts of the structure for each solution.

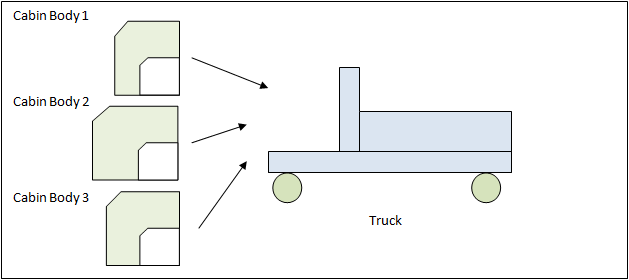

Figure 1: Illustration depicting an application of subcase specific modeling.

In Figure 1, each cabin body can be defined as a specific element set and the common parts will make up one element set. These can be independently combined under three different subcases with different boundary conditions and solved in one single solver run.

The subcase specific modeling functionality is realized with the use of element sets and the subcase selector entry SUBMODEL. The SUBMODEL entry can be used within a specific subcase in the Subcase Information section to select a certain element set for the solution.

The full model may consist of several common or shared sections which remain constant while other sections are changed to find the best fit for a particular application. In such cases, the SUBMODEL entry can be used to choose a set of elements for selective solution. The element set identification number is the only input required for this entry.

SUBMODEL, SID, SID_r

The fields “SID” and “SID_r” specify the identification numbers of the element and rigid element sets, respectively defining the submodel that is solved within this subcase. The “SID_r” field is optional. Refer to the OptiStruct Reference Guide for detailed information.

$ Subcase Information Section

SUBCASE 1

$ Submodel specific SPC’s and LOAD’s can be defined here.

SUBMODEL, 11

SUBCASE 2

$ Submodel specific SPC’s and LOAD’s can be defined here.

SUBMODEL, 12

$ Bulk Data Section

SET, 1, ELEM $ defines the shared/common part, for example, the chassis, bed and wheels in Figure 1

SET, 2, ELEM $ defines the individual part, for example, cabin body 1 in Figure 1

SET, 3, ELEM $ defines the individual part, for example, cabin body 2 in Figure 2

SET, 11, ELEM, OR, 1, 2 $ defines the full truck model with cabin body 1 and the common parts

SET, 12, ELEM, OR, 1, 3 $ defines the full truck model with cabin body 2 and the common parts

| 1. | Single Point Constraints (SPC), Loads (LOAD), Multi Point Constraints (MPC) and other similar subcase selectors should define attributes only applicable to the specific submodel or substructure. These attributes should apply exclusively to the subcase-specific model defined via SUBMODEL. The SUBMODEL entry does not trim the specified attributes (loads, constraints and so on) to the defined subcase. |

| 2. | This functionality is currently available for linear static analysis only. All optimization types with responses from Linear Static analysis are supported (except SPCFORCE/residual force responses). |

| 3. | There is no restriction on the use of GRID’s. If two submodels have a GRID at the same location, you can use the shared GRID entry or two separate GRID entries. |

| 4. | For subcase specific configuration, definition of all rigids and CONNECT entries are processed with INSTANCE-based relocations. |

Global-local analysis is a technique in which a full model is solved using two (or more) submodels; one submodel represents the full structure but at a lower accuracy (for example, a larger mesh size) and the second submodel represents only a part of the structure (for example, using a smaller mesh size). The global structure is solved first and the displacements from the selected zone are interpolated and applied to the local structure. Global-local analysis is implemented with the use of the subcase specific modeling technique defined above.

Global-local modeling is only an approximation, and its use depends on the assumption that a more accurate local model will not significantly affect the displacements of the global structure. This process should not be used whenever small stiffness changes in the local submodel may have a large impact on the solution outside of it.

Global-local analysis may help improve results in models with local stress concentrations. Parts of the structure with small details which require relatively higher accuracy can be modeled as local submodels with a fine mesh and the full structure can be modeled using a coarse mesh. This allows for faster solution times as only a part of the structure is being solved with a fine mesh.

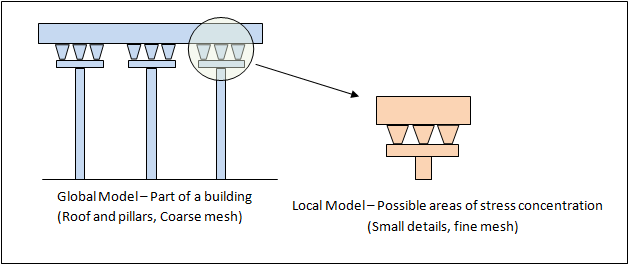

Figure 2: Illustration depicting an application of global-local analysis.

In Figure 2, an example building is illustrated wherein sections containing the pillar-roof joint are modeled as separate submodels with a refined mesh. The finer mesh allows for better accuracy at regions with high stress concentrations. Using the global-local analysis capability, the results from the coarser global model are interpolated and applied to the finer mesh of the local model at the cut surface. This allows for the local model to be driven by the results of the global model.

The global-local modeling functionality is realized with the help of the subcase specific modeling feature and the subcase selector entry GLOBSUB. This entry is defined in the subcase which contains the local model definition. The GLOBSUB entry in the subcase section for a local model identifies the global model (SUBCASE ID) which is used to drive the specific local model. This global-local relationship applies only to these two subcases. There may be many such pairs in the input deck, multiple subcases can be set as ‘global’, and it is possible to use the local model from one pair as a global for another subcase.

The full model consists of several sections with areas of high stress concentration or regions of interest which require a higher accuracy. In such cases, the entire model can be solved with a coarser mesh and in each local subcase defining the submodel of interest, the global structure can be referenced using the GLOBSUB entry. The set of grids within the local structure at the cut surface of displacement should be specified.

GLOBSUB, SUBID, SID

The field “SUBID” specifies the identification number of the subcase that contains the global structure definition (SUBMODEL) and the field “SID” specifies the set of grid points in the local structure that defines the displacement cut surface. The displacements from the global structure are applied to this set of grid points. All grids in this set should belong to the local substructure. Refer to the OptiStruct Reference Guide for detailed information.

The save/restart functionality of the Global-Local modeling allows you to save results of one or more global subcases. Additionally, you may choose to modify the input deck of local subcases and/or add more local subcases to be solved, and rerun the model without solving the global subcase multiple times. The global subcase results can be recovered from the previously saved restart file. Currently this functionality is available for Linear Static Analysis only.

| Note: | The global subcase still needs to be present even if the restart job is performed with GETDISP. In that case, the solution of global subcase will be skipped and the results are directly recovered with GETDISP. |

Insert the following entry in the control section of the Subcase to be saved:

ASSIGN, SAVEDISP, <Filename>

Insert the following entry in the control section of the Subcase to be recovered:

ASSIGN, GETDISP, <Filename>

Refer to the ASSIGN entry for further information.

$ Subcase Information Section

SUBCASE 1

$ Submodel specific SPC’s and LOAD’s can be defined here.

SUBMODEL, 11

SUBCASE 2

$ Submodel specific SPC’s and LOAD’s can be defined here.

SUBMODEL, 12

GLOBSUB, 1, 15

$ Bulk Data Section

SET, 11, ELEM |

$ defines the global structure, for example, the full building in Figure 2 |

SET, 12, ELEM |

$ defines the local structure, for example, the pillar-roof joint in Figure 2 |

SET, 15, GRID |

$ defines the cut surface, for example, the interface grids of the pillar-roof joint in Figure 2 at which the displacements are interpolated. |

| 1. | Solution transfer between local and global substructures uses 2D and 3D elements in the global model to interpolate the displacements and rotations at each GRID location belonging to the cut surface set SID. It is recommended that no other elements (beams, rods, or rigids) are near the cut surface in the global structure, as the solution of these elements will not affect the local model. More specifically, the cut surface should be selected such that in the global structure there are no GRID’s which are connected only to 1D or rigid elements. |

| 2. | Solution in the elements near the cut surface in the local model may lead to some noise resulting from interpolation from the global substructure, and should be discarded from the results. Actual zone of interest (for example, stress concentration) should be separated from the cut surface grids by a minimum of two layers of elements in the local model. |

| 3. | Cut surface should consist only of grids on the cuts (sections) through the structure. Usually, free edges/surfaces without any loading or support conditions should not be part of the cut surface. |

| 4. | There is no requirement that the cut surface grids exist only on the boundary of the local model. For shell submodels, it may be beneficial to include all grids in the outer layer of elements, as it will improve the transfer of rotations between subcases. |

| 5. | When certain loading and/or support conditions of the global submodel remain in the local submodel, it is recommended to represent them with actual loads in a manner consistent with the accuracy of the local model. For instance, point loading of the global shell structure should be replaced with equivalent by more realistic distributed loading on the local solid substructure. Alternatively, you could decide not to apply the loading/support conditions to the local submodel. In such cases, the grids in the originally loaded/supported area(s) should be included in the cut surface so that the displacements from the global submodel are interpolated and applied to the local structure. However, this technique may significantly reduce accuracy of the local solution. |

| 6. | The cut surface may represent single or multiple cuts (sections) through the structure. Multiple cuts should be separated from each other, that is, they should not exist closer than the element size of the global model. |

| 7. | The GLOBSUB entry should always reference the subcase ID of a global subcase that is defined above its corresponding local subcase. |

| 8. | This functionality is currently available for linear static analysis only. All optimization types with responses from Linear Static Analysis are supported. |

Exceptions:

| • | SPCFORCE/residual force responses are not supported |

| • | Topology must lie outside the local part(s) and, any design variables affecting the local submodel should also be mapped to the global model. |