Static Ride Analysis |

|

|

|

|

|

Static Ride Analysis |

|

|

|

|

The Static Ride analysis is a simulation of both wheels moving up and down, in phase, with the steering wheel held fixed. The chassis is fixed-to-ground. The displacement of the wheel center is prescribed by the user. The suspension moves via a simple control system and a “suspension test rig”. The wheel is constrained at the tire patch location to the suspension test rig using an in-plane joint. Standard suspension requests (Caster, Camber, Toe, etc.) are included as part of the ride analysis and are described here. The Front and Rear suspension ride analyses are similar.

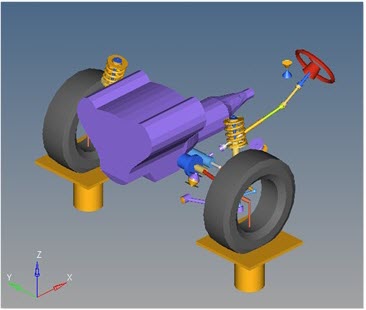

Front Suspension Static Ride Analysis

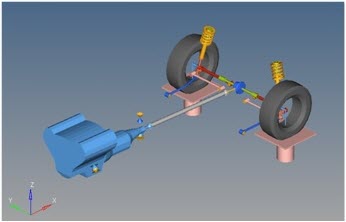

Rear Suspension Static Ride Analysis

The Static Ride analysis is designed to work with front and rear half vehicle models that have been built through the MotionView Assembly Wizard. The analysis should attach to the model automatically when added through the Task Wizard. The analysis can be used with models built by hand, as long as the attachment scheme in the analysis is strictly followed.

The analysis begins at Zero displacement (design position).

Time (in Seconds) |

Action |

|---|---|

0 to 2.5 |

Wheels moves from Design Position to Jounce Position |

2.5 to 5.0 |

Wheels moves from Jounce Position to Design Position |

5.0 to 7.5 |

Wheels moves from Design to Rebound Position |

7.5 to 10.0 |

Wheels moves from Rebound Position to Design Position |

10.0 |

Analysis Ends |

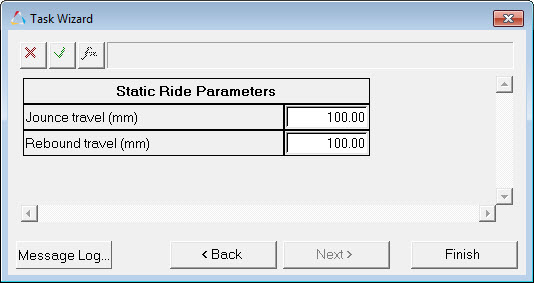

Suspension travel is entered on the Static Ride Parameters form in the analysis. Travel is assumed to be symmetric. The suspension displacement follows a simple harmonic function (sin wave) pattern.

Static Ride Parameters Dialog (Front Half)

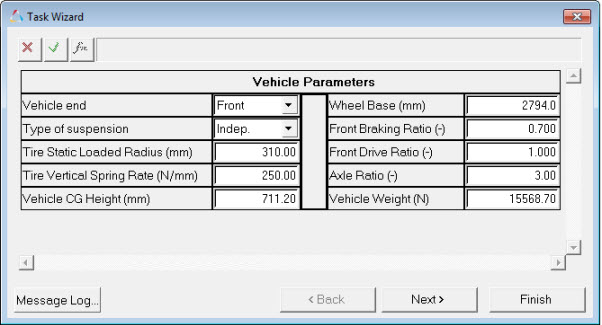

A total of forty-seven outputs are calculated, including all of the Suspension Design Factors. Input data for the SDF’s are entered on the Vehicle Parameters form in the Static Ride analysis (shown below).

Vehicle Parameters Dialog (Front Half)

The Static Ride analysis is a vertical displacement of the suspension, with the wheels moving in phase. The mechanism to perform this is described below:

| • | A Jack body is included in the analysis. |

| • | The Jack body is constrained to ground with a Translational joint, allowing the Jack body to only move in the vertical direction. |

| • | An Inplane joint constrains the jack to the wheel at the SLR distance entered in the Vehicle Parameters form. |

| • | The Solver Variables “Left Command Variable” and “Right Command Variable” define the desired displacement of the Jack bodies. |

| • | The Solver Variables “Left Feedback Variable” and “Right Feedback Variable” measure the distance in the Z direction between the wheel center point on the wheel, and the wheel center point on the ground. |

| • | Solver Differential Equations “diff left jack” and “diff right jack” are defined as the difference between the Feedback and Command variables. An IF statement and the MODE function is used to turn the Solver Differential Equation on during Statics and Quasi-statics and set it to zero (turning off the Solver Differential Equation) during the remaining analysis modes (Kinematics, Initial Conditions, Dynamics, and Linear Analysis). |

| • | A Force “Jack Vertical Actuator” is defined to be the DIF (value) of the Solver Differential Equation “diff left jack” using an expression. |

| • | The Jack Vertical Actuator force moves the suspension through jounce and rebound. The force magnitude is determined by the Differential Controller value. |

The control diff (a simple control system) is used for two reasons:

| - | The control system and test rig mechanism does not add constraints to the suspension. This allows the wheel center compliance matrix to be calculated easily, which is used in the suspension design factor calculations. |

| - | A Force is applied on the test rig “Jack” to move the wheel center vertical (Z) displacement through a prescribed motion. A control system is required for this type of system. |

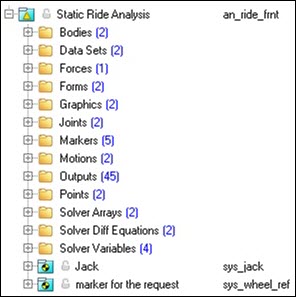

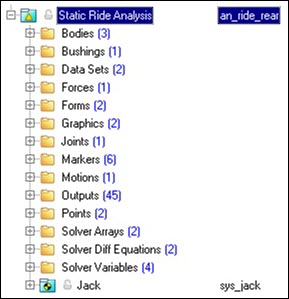

The entities in the analysis are displayed in the MotionView Project Browser as shown in the image below:

Project Browser View - Front Half - Static Ride Analysis

Project Browser View - Rear Half - Static Ride Analysis

Nine types of modeling element containers are used to define the analysis. One sub-system (a Drive torque controller) is also included in the analysis.

Thirteen modeling element types are used in the front analysis and fourteen modeling element types are used in the rear suspension analysis (see below). The sub systems “Jack” and “Marker for Request” are also described below.

The analysis uses the standard analysis attachment. The attachments resolve automatically if the model is built through the Model Wizard. The attachments contain the minimum data the analysis needs to run the analysis. The attachments are standard for most analyses.

Front Half Static Ride Analysis - Attachments

Rear Half Static Ride Analysis - Attachments |

Two bodies are used in the Front Half Static Ride analysis, “Jack” and “Dummy body”. The “Jack” is used to simulate a platform moving vertically to displace the suspension. The "Dummy body" is included in the analysis to make the system compatible with ADAMS modeling. The "Dummy body" is attached to the knuckle with a fixed joint and has no role in the analysis when it is run in MotionSolve.

Project Browser View - Bodies - Front Half Static Ride Analysis The Rear suspension analysis is shown below. The “Dummy body for DOF” body is included to make the Degrees of Freedom work out for certain suspensions. The Dummy body is constrained to ground with a soft bushing.

Project Browser View - Bodies - Rear Half Static Ride Analysis |

There are no bushings in the Front suspension analysis. One bushing is included in the Rear Half suspension analysis, “Dummy bush for DOF”. The ‘Dummy bush for DOF” constrains the “Dummy Body for DOF” body to ground with a soft bushing rate. The bushing is used to make the Degrees of Freedom work properly for certain models.

Project Browser View - Bushings - Rear Half Static Ride Analysis |

Two datasets are used in the system, "Vehicle Parameters" and "Suspension travel". The "Suspension travel" dataset is used to store the suspension travel inputs for jounce and rebound. Edit the parameters on the “Suspension travel” form. The "Vehicle Parameters" dataset is used to store data used to calculate the Suspension Design Factors. Edit the input values on the “Vehicle Parameters” form. The input values, and their use is described in depth in the Suspension Design Factors section.

Project Browser View - Datasets - Front Half Static Ride Analysis

Project Browser View - Datasets - Rear Half Static Ride Analysis

Dataset Property Dialog - Datasets "Vehicle Parameters"

Dataset Property Dialog - Datasets "Suspension Travel" |

The Front and Rear Static Ride analyses include one force pair, the “Jack Vertical Actuator”. This force applies a vertical force on the jack which moves the suspension into jounce and rebound. The Force is controlled by a DIF statement. The browser view of the force is shown below:

Project Browser View - Force - Front Half Static Ride Analysis

Project Browser View - Force - Rear Half Static Ride Analysis |

Two Forms are included in the Static Ride Analysis. These Forms are used to modify the inputs into the analysis. The “Vehicle Parameters” form is used to edit the inputs used to calculate the Suspension Design Factors. The Suspension Design Factors are described in detail in here. The “Static Ride Parameters” are the jounce and rebound travels used in the analysis. Modify the values to match the desired Wheel Center vertical travel in your suspension. The front and rear forms are the same.

Project Browser View - Forms - Front Half Static Ride Analysis

Project Browser View - Forms - Rear Half Static Ride Analysis

Vehicle Parameters Dialog - Forms - Front Half Static Ride Analysis

Static Ride Parameters Dialog - Forms - Front Half Static Ride Analysis |

Two Graphics are defined in the Front and Rear Static Ride Analysis, “Jack Cylinder” and “Jack Patch”. The graphics represent test apparatus used to exercise the front suspension.

Project Browser View - Graphics - Front Half Static Ride Analysis

Jack Graphics Example |

Two joints, “Dummy Fixed to Knuckle” and “Rack Dummy Ball” joints are included in the Front Half Static Ride analysis; one joint, “Dummy Fixed to Knuckle” is included in the Rear Half Static Ride analysis. "Dummy Fixed to Knuckle" is a fixed joint which attaches the Knuckle to the Dummy body. The dummy joints are included to constrain dummy bodies. The dummy bodies are used to make certain analyses work with ADAMS.

Project Browser View - Joints - Front Half Static Ride Analysis

Project Browser View - Joints - Rear Half Static Ride Analysis

Joints Panel - Dummy Fixed to Knuckle Joint - Front Half Static Ride Analysis

Joints Panel - Rack Dummy Ball Joint - Front Half Static Ride Analysis |

Five markers are included in the Front Half Static Ride; six markers are used in Rear Half Static Ride analysis. The markers are described in the tables located below: Front Suspension Markers

Rear Suspension Markers

Project Browser View - Markers - Front Half Static Ride Analysis

Project Browser View - Markers - Rear Half Static Ride Analysis |

|---|

Two motions are included in the Front Half Static Ride analysis, and a single motion is included in the Rear Half Static Ride analysis. The “Wheel spindle motion” is used in both front and rear, and the “Steering wheel motion” is used in front analysis. The "Wheel spindle motion" fixes the wheel to the knuckle to prevent wheel rotation. The "Steering wheel motion" is used to hold the steering wheel during most analyses, and is used to turn the steering wheel during a steering analysis. The "Wheel spindle motion" is deactivated and not used in both the front and rear ride analyses.

Project Browser View - Motions - Front Half Static Ride Analysis

Project Browser View - Motions - Rear Half Static Ride Analysis |

Forty Five Outputs are included in both Front and Rear Static Ride analyses.

Project Browser View - Outputs - Front and Rear Half Static Ride Analysis |

Two point pairs are defined in the Front and Rear Half Static Ride analyses. The points are used to create the Jack graphics and are referred to by the analysis markers. The points contain parametric logic to define their X, Y, and Z locations. No user modification of any points should be necessary. The point pairs for both the Front and Rear analyses are described in the table below:

Project Browser View - Points - Front Half Static Ride Analysis

Project Browser View - Points - Rear Half Static Ride Analysis |

There are two solver arrays in the Front and Rear Half Static Ride analyses; "Vehicle parameter array" and "Testrig parameter array". The "Vehicle parameter array" contains vehicle information that is used to calculate the SDF’s. Some of the data is also used in the analysis to create point locations and forces. The data is entered in the Vehicle Parameter Form. The "Testrig parameter array" contains point, force and motion data, and is passed to the SDF subroutine and used to run the SDF calculation analysis. The "Testrig parameter array" is symbolically defined and should not require editing.

Testrig Parameter ArrayThe Testrig array is populated by the analysis using the symbolic logic provided by MotionView and should not require editing. The Testrig parameters are defined in the table below:

Project Browser View - Solver Array - Front Half Static Ride Analysis

Project Browser View - Solver Array - Rear Half Static Ride Analysis |

The Front and Rear Half Static Ride include two solver differential equations, Differential left jack and Differential right jack. The Solver Differential Equations are part of the control system used to move the suspension through the requested travel. The Solver Differential Equations are similar for both the front and rear suspensions. The front left equation is as follows: IF(mode-4:0,0,1)*IF(mode-7:1,0,0)*(VARVAL(31000200)-VARVAL(31000100)) A break down of the equation is provided below:

As a result:

The Solver Differential Equation maintains the wheel displacement due to the following property of Solver Differential Equations: For static and quasi-static solutions, the derivative of the dynamic state is set to zero. This converts the Control_Diff to an algebraic equation for these two analyses. See the Control_Diff topic in the MotionSolve Reference Guide for additional information.

Project Browser View - Solver Differential Equations - Front Half Static Ride Analysis

Project Browser View - Solver Differential Equations - Rear Half Static Ride Analysis

Panel View - Solver Differential Equations - Front Half Diff Left Jack

Panel View - Solver Differential Equations - Front Half Diff Right Jack |

The Static Ride analysis consists of four solver variables:

Solver variables are part of the wheel displacement control system. Each Solver variable is described in the table below:

Plot of the Left WC Command Variable vs. Time

Project Browser View - Solver Variables - Front Half Static Ride Analysis

Project Browser View - Solver Variables - Rear Half Static Ride Analysis

Panel – Solver Variable - Front Half Left Feedback Variable

Panel – Solver Variable - Front Half Left Command Variable |

Many of the half car analyses use a control system to displace the wheels in Jounce and Rebound. The system applies a Force on the Jack to move the wheel center through a displacement defined by the “Left Command Variable” and “Right Command variable”. The control system only works while running Statics and Quasi-statics solutions. A diagram of the system is shown below. The solver statements that are written for some MotionView entities are shown in the diagram. The system is symmetric, and the front and rear suspensions use a similar scheme.

A description of the system is as follows (from top to bottom of the diagram):

Element DescriptionA detailed description of the elements included in the Wheel Control System are provided below:

How The Wheel Control System WorksThe wheel control system works as follows:

|

The Jack has two joints and three vectors in it. The joints connect the jack to ground and to the wheel. The vectors are parallel to the Global axes and are used as reference vectors. The graphics of the Jack are in the analysis template, which in this case is the ride analysis.

Figure-Jack system Modeling Entities

|

The “Marker for the request” system contains four markers that are used for output requests. The markers are at the wheel center and at the Tirepatch (GeomU) for the Left and Right wheels. All markers are on ground and are oriented to be parallel to the global coordinate frame. The markers are used to measure wheel center or tirepatch travel in output requests.

Left Wheelcenter Marker |