Swept Sine |

|

|

|

|

|

Swept Sine |

|

|

|

|

A Swept Sine event simulates a vehicle driving at a constant speed with a sinusoidal steering input of constant magnitude but increasing frequency applied. Output Requests are included to measure the vehicle state variables, tire forces, and tire state variables. A Drive torque controller is used maintain the constant velocity of the vehicle. A plot template is available to plot the results.

Some Automotive OEM’s refer to this test as a frequency response test. The test is designed to measure the dynamic response of the vehicle to sinusoidal steering input.

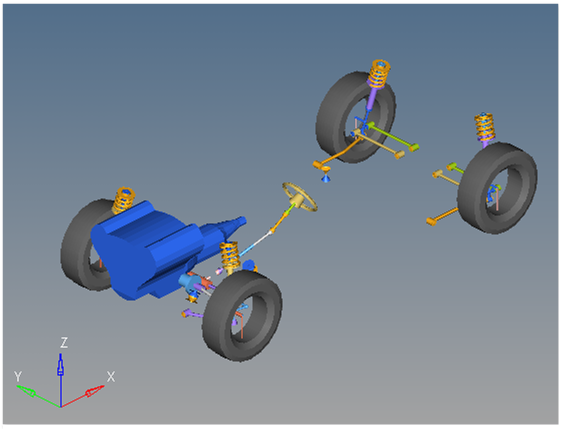

Swept Sine Event

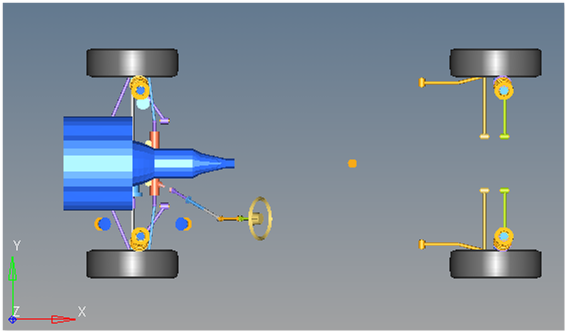

Top View of a Swept Sine Event

The Swept sine event is designed to work with a full vehicle model that has been built through the MotionView Assembly Wizard. The event should attach to the model automatically when added through the Task Wizard. The event can be used with models built manually, as long as the attachment scheme in the event is strictly followed.

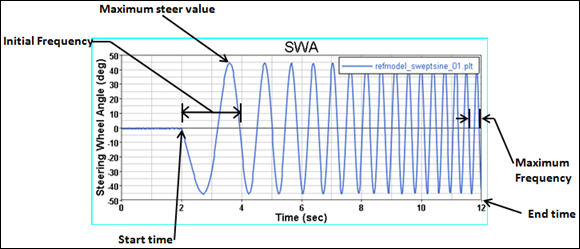

A sinusoidal steering input at the steering wheel determines the frequency response characteristics of the vehicle. The Vehicle velocity of 45 mph is kept constant throughout the event. After 2 seconds, the vehicle steers from its initial value to its maximum steering value, which is 45 degrees with a frequency increase rate of 0.2750 Hz/sec. This event covers a minimum frequency range of 0.25 to 3 Hz. This event helps to determine the steering wheel angle, yaw rate, roll angle, and lateral acceleration.

The initial Vehicle velocity, Initial and Maximum steer value, Initial and Maximum frequency, Frequency rate, Start and End time, and Time step can be modified via the event Form (shown below). The wheel rotational velocities are calculated values and should not be changed.

The simplified equation used to define the steering wheel angular input is:

![]()

Where:

![]() = Input steering wheel angle

= Input steering wheel angle

![]() = Maximum steer value

= Maximum steer value

![]() = Initial steer frequency

= Initial steer frequency

![]() = Frequency rate

= Frequency rate

![]() = Simulation time

= Simulation time

The actual equation used to define the steering wheel angle has additional terms to translate from degrees to radians, to limit the input frequency to the defined Maximum frequency, and to transition from the initial zero steer value to the sin function. The Templex expression for the equation is:

`{ds_swept_sine.max_str.value}*DTOR

*STEP(TIME, {ds_swept_sine.st_tim.value}, 0.0, {ds_swept_sine.st_tim.value}+0.001, 1.0)

*SIN(2*PI

*(min({ds_swept_sine.max_frq.value},{ds_swept_sine.ini_frq.value}+(({ds_swept_sine.frq_rt.value}/2)

*(TIME-{ds_swept_sine.st_tim.value}))))*(TIME-{ds_swept_sine.st_tim.value}))`

The equation evaluates to the following:

45*DTOR*STEP(TIME, 2, 0.0, 2+0.001, 1.0)*SIN(2*PI*(min(3,0.25+((0.275/2)*(TIME-2))))*(TIME-2))

The expression performs the following function, broken down by line:

ds_swept_sine.max_str.value is the symbolic representation of the Maximum steer values from the dataset named “ds_swept_sine”, found in the Swept sine event. .value indicates the input value should be used in the expression. DTOR is the conversion factor from degrees to radians. |

The STEP function evaluates to zero before ds_swept_sine.st_tim.value (swept sine start time) and evaluates to one when the solution time is (swept sinestart time + .001). The step is used to transition from a zero steering wheel angle to the increasing frequency sine wave. |

The sin(2*PI takes the sin of the remainder of the equation. 2*PI converts frequency to radians. |

The min function takes the minimum of either the maximum frequency value or the product of the two. |

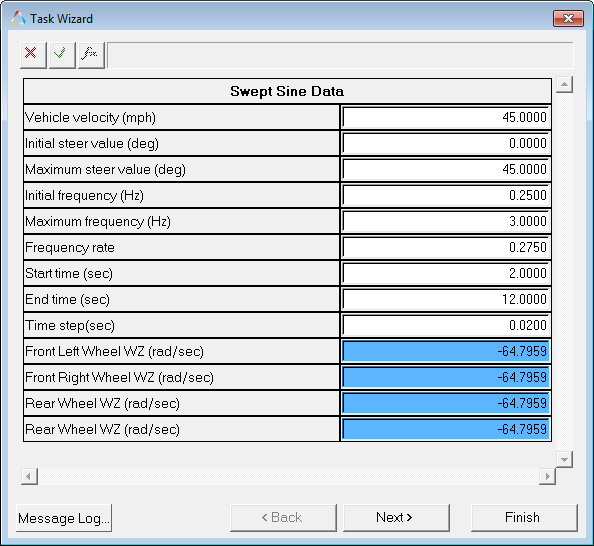

Swept Sine Data Dialog

Input |

Description |

|---|---|

Vehicle Velocity |

The constant speed that the vehicle attempts to maintain during the event. |

Initial Steer Value (deg) |

Not currently used in the event. |

Maximum Steer Value (deg) |

The maximum steering angle of the sine wave function applied to the steering wheel. |

Initial Frequency (Hz) |

The initial input frequency of the steering wheel sine wave. |

Maximum Frequency (Hz) |

The maximum frequency sine wave that can be applied to the steering wheel. |

Frequency Rate |

The rate of change of frequency (hz/sec) of the sine wave function applied to the steering wheel. |

Start Time (sec) |

The start time of the sine wave steering function application to the steering wheel. |

End Time (sec) |

End time of the simulation. |

Time Step (sec) |

The output data time step. |

Note that the Maximum frequency is a frequency limit only. The actual maximum frequency obtained in the simulation is a function of the Initial frequency, the Frequency rate, and the Start and End time. The steering wheel sine wave begins at the Initial frequency at the Start time and increases by the Frequency rate each second until the event ends at the End time. The maximum frequency only comes in to effect if the End time is mismatched with the Frequency rate.

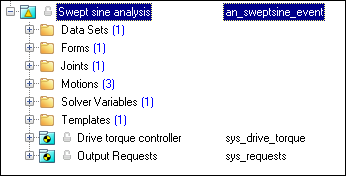

The entities in the event are displayed in the MotionView Project Browser as shown in the image below:

Project Browser View - Forms - Swept Sine Analysis

Six types of modeling element containers are used to define the event (see below). Two sub systems (a Drive torque controller and Output Requests) are also included during the event.

The event uses the standard event attachment. The attachments resolve automatically if the model is built through the Model Wizard. The attachments contain the minimum data the event needs to run the analysis. The attachments are standard for most events.

Swept Sine Event - Attachments |

One dataset is used in the system, which contains the data used to describe the Swept sine event. The event allows you to set the initial Vehicle velocity, Initial And Maximum steer value, Initial and Maximum frequency, Frequency rate, Start time, End time and Time step. The wheel rotational velocities and ground height are calculated values and should not be changed.

Project Browser View - Datasets - Swept Sine Analysis

Dataset Property Data Dialog - Swept Sine Analysis |

The Form is the only place that you should change the Swept sine event. Initial Vehicle velocity, Initial steer value, Maximum steer value, Initial frequency, Maximum frequency, Frequency rate, Start time, End time and Time step are the parameters that can be changed. The wheel rotational velocities are calculated values and should not be changed.

Project Browser View - Forms - Swept Sine Analysis

Swept Sine Data Analysis - Form Dialog |

A ball joint is included in the Swept sine event. The joint attaches a dummy body to the steering rack. The joint is included to make certain events work in ADAMS. Attach the dummy body to the steering rack if building a model manually.

Project Browser View - Joints - Swept Sine Analysis

Joints Panel - Swept Sine Analysis |

Three motions are included in the event. The steering motion is used in the template which gives the input for the vehicle to steer and acts on a revolute joint that connects the steering wheel to the vehicle body. If a steering column is not included in the model, the motion acts on the joint between the steering rack input shaft and the vehicle body. The Front and Rear Wheel Motions act on the wheel spindle revolute joints that connect the wheel hub to the knuckle. The motion is initially zero (fixing the wheels to the knuckle) so the model converges statically. The wheel locking motions get deactivated after the convergence of the static analysis to allow the tires to rotate during dynamic analysis.

Project Browser View - Motions - Swept Sine Analysis |

The Swept sine consists of only one solver variable, the Swept Sine Variable, which is an expression. It is used in the templates.

Project Browser View - Solver Variables - Swept Sine Analysis

Solver Variable Panel - Steer Path Variable |

A template is included in the Swept sine event task. The template is solver specific and only the MotionSolve template is documented. The template is inserted in the solver deck after the </Model> command and controls the execution of the event.

Project Browser View - Templates - Swept Sine Analysis The template for this event is shown below:

|

ISO +7401-2003 - Road vehicles — Lateral transient response test methods — Open-loop test methods.