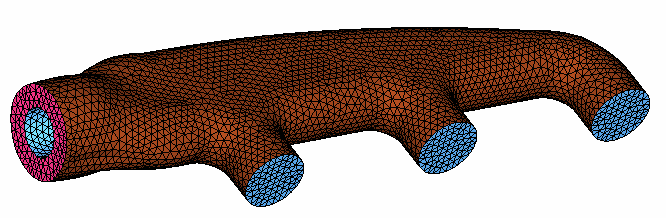

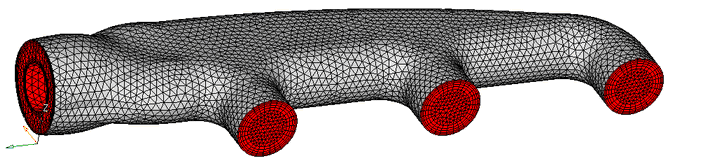

| 1. | Click Mesh > Volume Mesh 3D > CFD Tetramesh. |

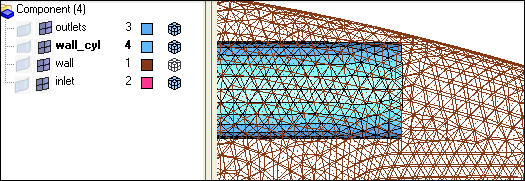

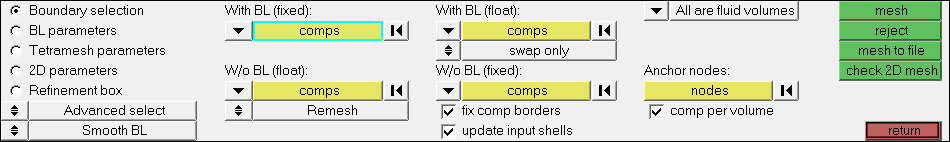

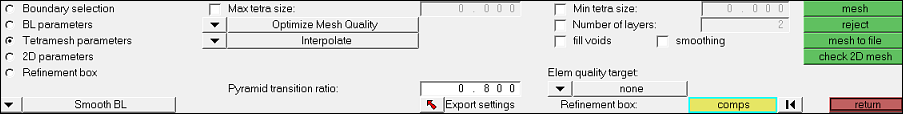

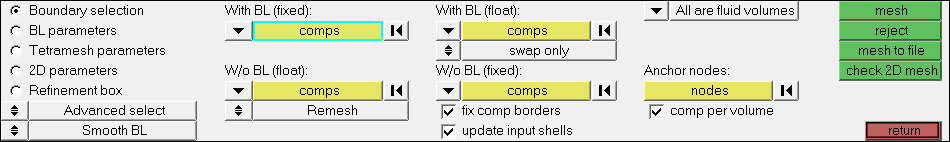

| 2. | Click the Boundary selection subpanel. |

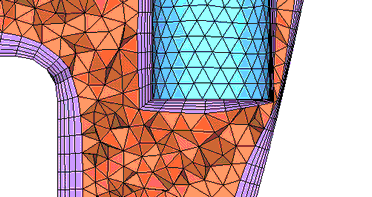

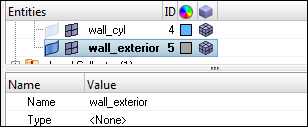

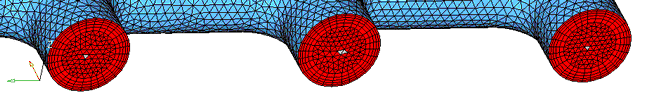

| 3. | Under the heading With BL (fixed), click comps and select the collectors wall and wall_cyl. |

| 4. | Under the heading W/o BL (float), click comps and select the collectors inlet and outlets. |

| 5. | Ensure that the switch below the W/o BL (float) selector is set to Remesh. This means that the surface meshes associated with those components will be remeshed or rebuilt after shrinking due to boundary layer growth from adjacent boundary layer components. |

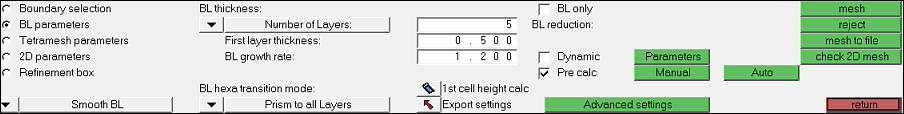

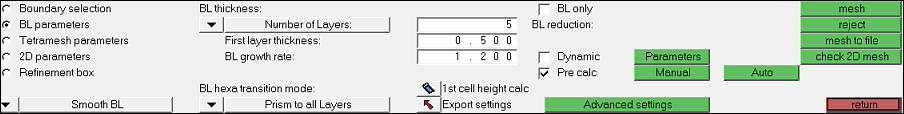

| 7. | Click the BL parameters subpanel. |

| 8. | Set the following fields: |

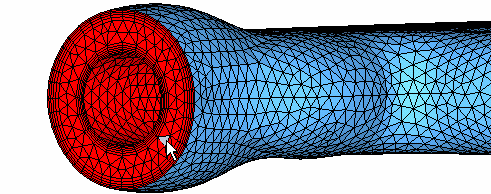

| • | First layer thickness = 0.5 |

| • | BL growth rate = 1.2 (This non-dimensional factor controls the change in layer thickness from one layer to the next). |

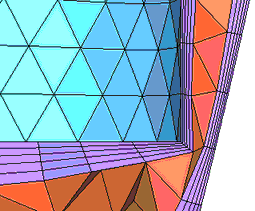

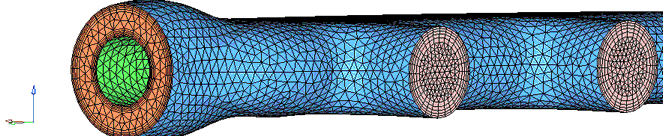

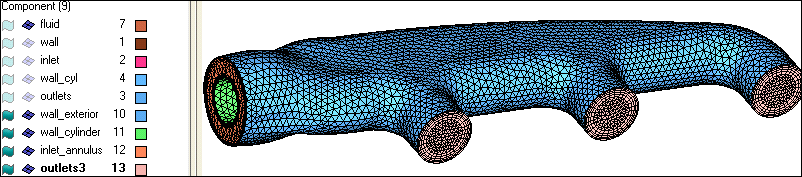

| • | BL hexa transition mode = All Prisms (Prism to all Layers). This means that if there are any quad elements in the surface mesh, those will be split into two trias each so that there is no need to transition from quad faces to tria faces when transitioning from the last boundary layer to the tetrahedral core. This option is very important when there are quad elements on areas with (low) distributed BL thickness ratio, because in such areas the thickness of the transition elements (for example, simple pyramid) was not taken into account when doing the interference study to assign distributed BL thickness ratio to those elements. |

| 9. | Check the box for Pre calc and then click Auto. The Generate Boundary Layer distributed thickness values dialog opens. Notice that the four components selected in the Boundary selection subpanel are already added. |

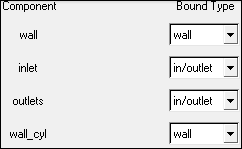

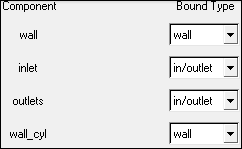

| 10. | Set the correct Bound Type for each one of the selected components. You want to generate a boundary layer from components wall and wall_cyl, therefore, you will leave wall as their Bound Type. Also verify that the Bound Type of components inlet and outlets is set to in/outlet as shown, following: |

A component with Bound Type: wall indicates that you are going to generate a boundary layer mesh on the component later on when you generate the mesh. Therefore, the same component should be consistently specified with the comps selector for the With BL (fixed or float) in the Boundary selection subpanel.

A component with a Bound Type: slip, symmetry, in/outlet, or farfield indicates that you are NOT going to generate a boundary layer mesh on the component. Therefore, when you generate the mesh this component should be consistently specified with the comps selector for the W/o BL (fixed or float) in the Boundary selection subpanel.

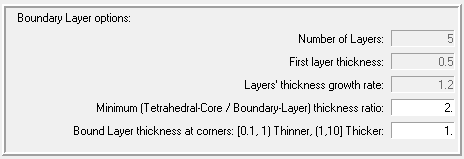

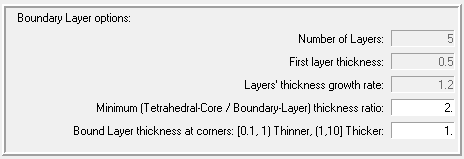

11. Specify the Boundary Layer options as shown in the following image.

| • | The first three fields are set in the BL parameters subpanel and cannot be changed here. All layers will have the same thickness except in area affected by the distributed thickness "loading" and also mesh smoothing operations such as hyperbolic smoothing at corners. |

| • | Specify a Minimum (Tetrahedral-Core / Boundary-Layer) thickness ratio value of 2.0. This means that in areas where there is not enough room to grow the nominal BL (5 layers starting with a thickness of 0.5 and increasing with a grow rate of 1.2), the boundary layers’ thickness will be reduced so that the tetrahedral core thickness is approximately at least 2.0 times the total boundary layer thickness, except for mesh smoothing operations such as hyperbolic smoothing at corners and convex/concave areas. |

| • | The last option, Bound Layer thickness at corners, is a coefficient that controls the hyperbolic growth where walls make an angle. The smaller this value is, the thinner the total BL thickness is in such areas; values less than 1 produce thinner layers and values greater than 1 produce thicker layers. |

Now you are ready to generate the Distributed BL Thickness loading. Make sure that none of the elements specified in the boundary collectors are masked. If they are masked an error message will indicate that there is a discrepancy between the total number of elements in the components that you specified and the number of tria3/quad4 elements found (displayed). If you have masked elements, you can use mask (F5), and press unmask all.

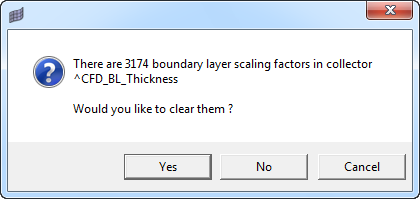

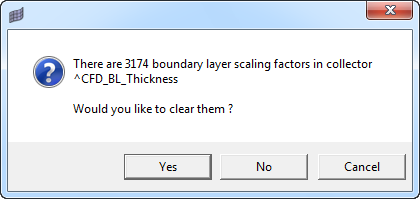

12. Click Generate Distributed BL Thickness Ratio. If the model already contains boundary layer thickness ratios, then a pop-up message box will ask you if you want to keep such loads or if you want to clear/discard them. Most of the time you will want to clear the existing boundary layer thickness ratios; click Yes. In some special cases you may want to keep them, if more than one loading value is specified for a node, the minimum value is used when generating the mesh.

13. After a few seconds you will see a pop-up message indicating the number of distributed boundary layer thickness values included in collector ^CFD_BL_Thickness.

14. Click Close in the Generate Boundary Layer distributed thickness values dialog.

|