Use the Spotweld panel to create 1D elements to connect different parts.

Spotwelds can be created by using one of the following subpanels:

|

uses surface geometry obtained from CAD data

|

|

uses finite element model data

|

|

internally remeshes the surrounding elements

|

Spotwelds can be created one at a time or in groups.

The 1-D element types you can create with the Spotweld panel include:

Elem type

|

Elem config

|

Screen display

|

External interfacing

|

bar2

|

60

|

A line between two nodes with BAR2 written at the centroid of the element.

|

Consult HyperMesh Entities and Solver Support section to determine which solvers support bar2 elements.

|

gap

|

70

|

A line between two nodes with GAP written at the centroid of the element.

|

Translates to CGAP element in OptiStruct, Nastran, or *GAP option in Abaqus.

|

plot

|

2

|

A line between two nodes.

|

|

rigid

|

5

|

A line between two nodes with the letter R written at the centroid of the element.

|

Translates to RBE2 in OptiStruct, Nastran, or *MPC in Abaqus

|

rod

|

61

|

A line between two nodes with ROD written at the centroid of the element.

|

Translates to CWELD/ CROD/ CTUBE/ CONROD in OptiStruct, Nastran, or a C1D2 element in Abaqus

|

spring

|

21

|

A line between two nodes with the letter K written at the centroid of the element.

|

Translates to CELAS1/ CELAS2/ CDAMP1/ CDAMP2/ CBUSH/ HMSPRING in OptiStruct, Nastran, or *SPRING in Abaqus

|

weld

|

3

|

A line between two nodes with the letter W written at the centroid of the element.

|

Translates to RBAR in OptiStruct, Nastran, or *MPC in Abaqus

|

Subpanels and Inputs

The Spotweld panel contains the following subpanels and command buttons:

Surfs-surfs option

If more than two surfaces are within the search radius, spotweld elements are not created. To create welds in this situation, select a pair of surfaces at a time.

The local coordinate systems are oriented with the y axis located along the direction between the selected nodes.

Welds are placed in the current component.

surfs-lines option

For all surfs/elems Engineering Solutions attempts to weld together all surfs/elems found within the given search radius. If more than two surfs/elems are found, Engineering Solutions attempts to weld all the layers together. This option is present to allow for 2t and 3t welds.

For ind surfs/elems Engineering Solutions finds the first surf/elem (within tolerance) in each collector via a database lookup.

| Note: | This may not be the closest surf/elem; it is simply the first one that is found. Placing too many elems/surfs in each collector may lead to unexpected results. |

|

The local coordinate systems are oriented with the y axis located along the direction between the selected nodes.

Panel Inputs

Input

|

Action

|

all surfs / ind surfs

|

all surfs: pick the surfaces in one step.

ind surfs: pick individual surfaces defining the independent and dependent regions.

|

surfs selector

|

Pick the independent surfaces.

If you select all surf, pick the two (or more) surfaces between which to create the element(s).

|

element config

|

The type of element to create.

|

weld location

|

The nodes or points located where you want to create spotwelds.

If you selected the lines option, each line is treated independently. This results in welds being located at the beginning and end of each line with the remainder of the welds being spaced evenly along the length of each individual line.

If you selected the line list option, all of the selected lines are combined head-to-tail in the order they were selected, and then treated as a single line. This results in only the beginning of the first line and the end of the last line having weld points, with the rest of the welds being spaced evenly along the length of the combined line.

|

property

|

Assign properties to the spotweld element(s).

Currently, bars, rods, springs, and gap elements are defined with a property ID.

|

search tolerance

|

The tolerance value to use to identify relevant surfaces between which to create the elements at the specified locations.

|

without systems / build systems

|

build systems: the local coordinate systems are built at each end of the spotweld element.

without systems: no systems are built.

|

spacing / density

|

Appears when lines-surfs option is selected.

| • | density: indicate the number of spotweld elements to be created along the line. |

| • | spacing: specify a set distance between the spotweld elements to be created along the line. |

|

offset options

|

You can either explicitly state the offset distance from each end on the line, or you can use the ½ spacing option. The ½ spacing option determines the distance between two welds and sets the explicit offset to ½ of this distance.

|

|

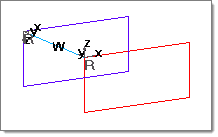

A weld built using build systems is illustrated below.

The illustration below shows a weld built using without systems.

Comments

The local coordinate systems are oriented with the y axis located along the direction between the selected nodes.

The dependent node can be moved to create weld elements that are perpendicular to the surface formed by the elements attached to the independent node. This relocation can occur either with or without pre-existing geometrical surfaces defining the "dependent surface."

Panel Inputs

Input

|

Action

|

indep node selector

|

Pick the independent node.

|

dep node selector

|

Pick the dependent node.

Engineering Solutions builds the element after you select the dependent node.

|

element config

|

The type of element to create.

|

move dep node

|

Activate the move dep node option if you want to move the dependent node along the surface in which it lies and create a spotweld normal to the independent surface. If the quality of the resulting mesh due to the movement of the dependent node is not acceptable, click reject and activate the remesh dep region option to remesh the dependent region. This option remeshes only the dependent region affected by the movement of the dependent node.

|

property

|

Assign properties to the spotweld element(s).

Currently, bars, rods, springs, and gap elements are defined with a property ID.

|

without systems / build systems

|

| • | build systems: the local coordinate systems are built at each end of the spotweld element. |

| • | without systems: no systems are built. |

|

|

If more than two elements are within the search radius, spotweld elements are not created. To create welds in this situation, select a pair of elements at a time.

The local coordinate systems are oriented with the y axis located along the direction between the selected nodes.

Welds are placed in the current component.

Panel Inputs

Input

|

Action

|

all elems / ind elems

|

| • | all elems: pick the elements in one step. |

| • | ind elems: pick individual elements defining the independent and dependent regions. |

|

elems selector

|

Pick the elements.

|

element config

|

The type of element to create.

|

weld location

|

The nodes or points located where you want to create spotwelds.

|

property

|

Select the property collector to be assigned to the element.

Currently, bars, rods, springs, and gap elements are defined with a property ID.

|

search tolerance

|

Enter the tolerance value to use to identify relevant surfaces between which to create the elements at the specified locations.

|

without systems / build systems

|

| • | build systems: the local coordinate systems are built at each end of the spotweld element. |

| • | without systems: no systems are built. |

|

attach to shell elems

|

Create 1-D connection elements and attach them to neighboring shell elements by internally remeshing the surrounding elements.

|

|

Panel Inputs

Input

|

Action

|

elems selector

|

Indicate the weld elements whose dependent and independent nodes you want to switch.

|

|

The following action buttons appear throughout the subpanels:

Input

|

Action

|

create

|

Creates the spotweld element.

|

reject

|

Reverts the most recent changes.

|

review

|

Displays the selected spotweld elements.

|

switch

|

Switches the selected elements.

|

return

|

Exits the panel.

|

|

See Also:

Spotweld Log file

Alphabetical List of Panels