RD-3599: Gasket with HyperMesh |

|

|

|

|

|

RD-3599: Gasket with HyperMesh |

|

|

|

|

This tutorial demonstrates how to simulate a rubber gasket in sequential loading, given the following load sequence:

| • | Translation Transverse (10 mm) |

| • | Translation Longitudinal (5 mm) |

| • | Torsion (20 Degrees) |

| • | UNITS: Length (mm), Time (ms), Mass (kg), Force (kN) and Stress (GPa) |

| • | Simulation time: |

| o | Engine [0 – 1.501] in steps of 0.5 ms for each load case |

| • | The outer circumference area is fixed on all degrees of freedom (VX, VY, VZ) and the center node is fixed on X direction and the X and Y rotation (VX, WX, Wy) |

| • | The gasket dimensions are: Thickness = 100 mm, External Diameter = 200 mm and Internal Diameter = 50 mm. |

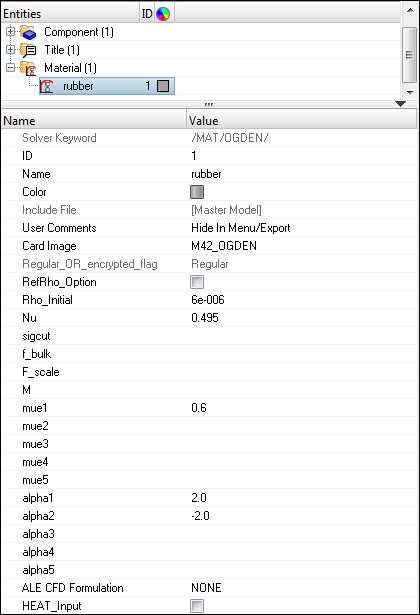

| • | Hyper-Elastic Material /MAT/LAW42 (Rubber) |

[Rho_I] Initial density = 6.0-6 Kg/mm3 [nu] Poisson’s ratio = 0.495 [mue1] ( [alfa1] ( (alfa2] ( |

Step 1: Load the RADIOSS (Block) User Profile

| 1. | Launch HyperMesh Desktop. |

| 2. | From the Preferences menu, select the User Profiles or click the |

| 3. | Select RADIOSS (Block140) and click OK. |

Step 2: Load the gasket.hm file

| 1. | From the toolbar, click the Open Model icon |

| 2. | Click Open. The model loads into the graphics area. |

Step 3: Define and assign material, property to Rubber

| 1. | In the Model browser, right-click and select Create > Material to create material. |

| 2. | For Name, enter rubber. |

| 3. | For Card Image, select M42_OGDEN and click Yes in the confirmation window. |

| 4. | Input the values, as shown below: |

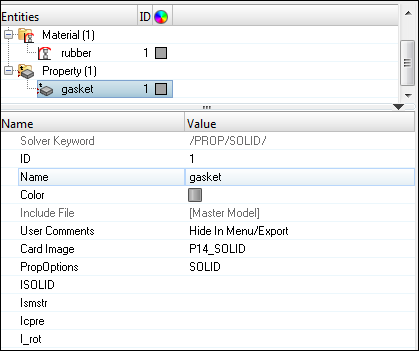

| 5. | In the Model browser, right-click and select Create > Property to create property. |

| 6. | For Name, enter gasket. |

| 7. | For Card Image, select P14_SOLID and click Yes to confirm. |

| 8. | In the Model browser, expand the Component folder and select GASKET. Right-click and Assign (or use the Entity Editor) the newly created property and material. |

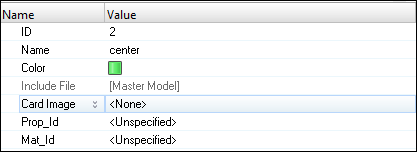

Step 4: Create a component for the rigid body at center of Gasket

| 1. | In the Model browser, right-click and select Create > Component. |

| 2. | For Name, enter center and switch Card Image to None and click Yes to confirm. |

| 3. | Select any color for easy visualization. |

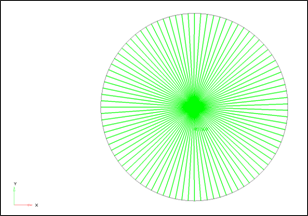

Step 5: Create a rigid body at center of Gasket

| 1. | From the 1D page, select the rigids panel. |

| 2. | For primary node, switch to calculate node. |

| 3. | For nodes 2-n, switch to multiple nodes. |

| 4. | Click the nodes and select a node in the inner face. |

| 5. | Click nodes and select by face. HyperMesh will select all nodes on the inner face. |

| 6. | Click create. |

| 7. | Click return to exit the panel. |

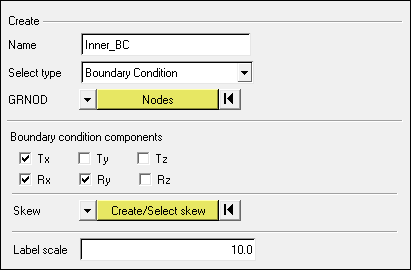

Step 6: Create gasket inner fixed boundary conditions

| 1. | From the Utility page, start the BCs Manager. |

| 2. | For Name, enter Inner_BC, set Select type to Boundary Condition and set the GRNOD to Nodes. |

| 3. | Select the master node of rigid body created in Step 5 and click proceed. |

| 4. | Check the Tx translational and Rx, Ry rotational degrees of freedom. |

| 5. | Click Create to create the inner fixed boundary condition. |

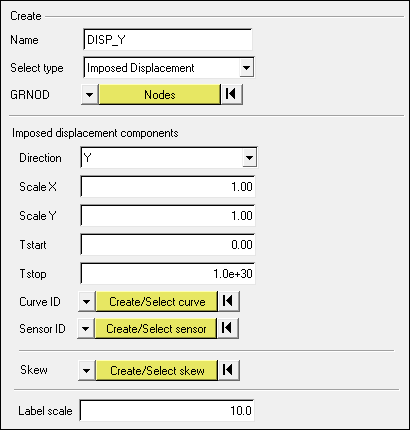

Step 7: Create gasket inner Y displacement boundary conditions

| 1. | From the Utility page, start the BCs Manager. |

| 2. | For Name, enter DISP_Y, set Select type to Imposed Displacement and set the GRNOD to Nodes. |

| 3. | Select the master node of rigid body created in Step 5. |

| 4. | Set Direction as Y. |

| 5. | Click Create/Select curve to go to the XY curve editor. |

| 6. | Click New and enter Name as DISP_Y. Click proceed. |

| 7. | Enter the following values for X and Y: |

X = {0, 0.5, 1.0}

Y = {0, 10, 10}

| 8. | Click Update and Close the XY curve editor GUI. |

| 9. | Click Create to create the boundary condition. |

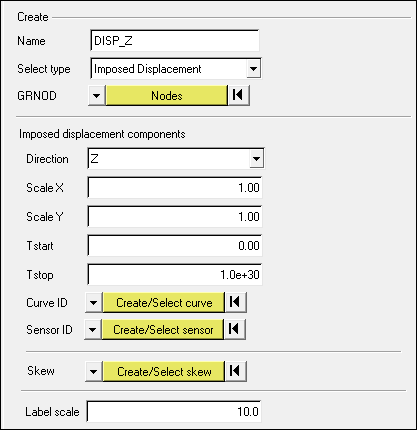

Step 8: Create gasket inner Z displacement boundary conditions

| 1. | From the Utility page, start the BCs Manager. |

| 2. | For Name, enter DISP_Z, set Select type to Imposed Displacement and set the GRNOD to Nodes. |

| 3. | Select the master node of rigid body created in Step 5. |

| 4. | Set Direction as Z. |

| 5. | Click Create/Select curve to go to the XY curve editor. |

| 6. | Click New and enter Name as DISP_Z. Click proceed. |

| 7. | Enter the following vales for X and Y: |

X = {0, 0.5, 1, 1.5}

Y = {0, 0, 5, 5}

| 8. | Click Update and Close the XY curve editor GUI. |

| 9. | Click Create to create the boundary condition. |

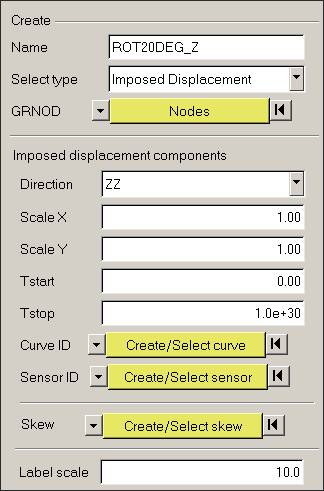

Step 9: Create gasket inner Z rotation boundary conditions

| 1. | From the Utility page, start the BCs Manager. |

| 2. | For Name, enter ROT20DEG_Z, set Select type to Imposed Displacement and set the GRNOD to Nodes. |

| 3. | Select the master node of rigid body created in Step 5. |

| 4. | Set Direction as ZZ. |

| 5. | Click Create/Select curve to go to the XY curve editor. |

| 6. | Click New and enter Name as ROT20DEG_Z. Click proceed. |

| 7. | Enter the following vales for X and Y: |

X = {0, 1, 1.5, 2}

Y = {0, 0, 0.349, 0.349}

| 8. | Click Update and Close the XY curve editor GUI. |

| 9. | Click Create to create the boundary condition. |

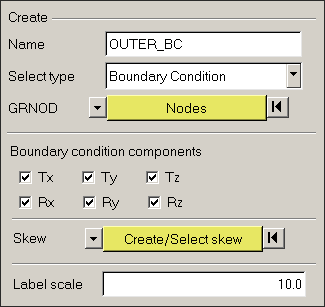

Step 10: Create gasket outer boundary conditions

| 1. | From the Utility page, start the BCs Manager. |

| 2. | For Name, enter OUTER_BC, set Select type to Boundary Condition and set the GRNOD to Nodes. |

| 3. | Click Nodes and select a node on the outer surface. |

| 4. | Click Nodes on the panel and then select by face to select all nodes on the outer surface. |

| 5. | Check all the translational and rotational degrees of freedom. |

| 6. | Click Create to create the outer fixed boundary condition. |

Step 11: Create output request and control cards

| 1. | Launch the HyperMesh Solver browser from View > Browsers > HyperMesh > Solver. |

| 2. | Right-click in the Solver browser general area to create the cards shown below with the given values for each parameter: |

Keyword Type |

Keyword |

Parameter |

Parameter Value |

|---|---|---|---|

CONTROL CARDS |

TITLE |

Status |

[Checked] |

CONTROL CARDS |

TITLE |

TITLE |

GASKET |

CONTROL CARDS |

MEMORY |

Status |

[Checked] |

CONTROL CARDS |

MEMORY |

NMOTS |

40000 Not needed |

CONTROL CARDS |

SPMD |

Status |

[Checked] |

CONTROL CARDS |

IOFLAG |

Status |

[Checked] |

CONTROL CARDS |

ANALY |

Status |

[Checked] |

ALE-CFD-SPH |

ALE_CFD_SPH_CARD |

Status |

[Checked] |

ALE-CFD-SPH |

ALE_CFD_SPH_CARD |

ALE_Grid_Velocity |

[Checked] |

ALE-CFD-SPH |

ALE_CFD_SPH_CARD |

GridVel_Gamma |

100.00 |

ENGINE KEYWORDS |

RUN |

Status |

[Checked] |

ENGINE KEYWORDS |

RUN |

RunName |

GASKET |

ENGINE KEYWORDS |

RUN |

Tstop |

1.51 |

ENGINE KEYWORDS |

PARITH |

Status |

[Checked] |

ENGINE KEYWORDS |

PARITH |

Keyword2 |

ON |

ENGINE KEYWORDS |

Status |

[Checked] |

|

ENGINE KEYWORDS |

N_Print |

-1000 |

|

ENGINE KEYWORDS |

ANIM/ELEM |

Status |

[Checked] |

ENGINE KEYWORDS |

ANIM/ELEM |

VONM |

[Checked] |

ENGINE KEYWORDS |

ANIM/ELEM |

DENS |

[Checked] |

ENGINE KEYWORDS |

ANIM/ELEM |

PRES |

[Checked] |

ENGINE KEYWORDS |

ANIM/VECT |

Status |

[Checked] |

ENGINE KEYWORDS |

ANIM/VECT |

CONT |

[Checked] |

ENGINE KEYWORDS |

ANIM/DT |

Status |

[Checked] |

ENGINE KEYWORDS |

ANIM/DT |

Tstart |

0 |

ENGINE KEYWORDS |

ANIM/DT |

Tfreq |

0.05 |

ENGINE KEYWORDS |

DT |

Status |

[Checked] |

ENGINE KEYWORDS |

DT |

Tscale |

0.0 |

ENGINE KEYWORDS |

DT |

Tmin |

0.0 |

ENGINE KEYWORDS |

TFILE |

Time frequency |

1.5e-3 |

Step 12: Export the model

| 1. | Click File > Export or click the Export icon |

| 2. | For File:, navigate to the destination directory where you want to export to. |

| 3. | For name, enter GASKET and click Save. |

| 4. | Click the downward-pointing arrows next to Export options to expand the panel. |

| 5. | Click Merge starter and engine file to export solver deck as one file (or export separately). |

| 6. | Click on Export to export solver deck. |

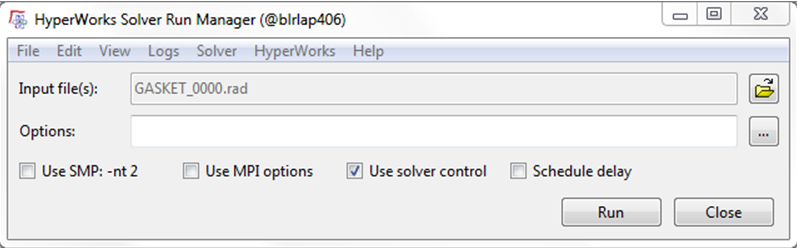

Step 13: Open RADIOSS Manager from windows Start menu

| 1. | Go to Start > Programs > Altair HyperWorks 14.0 > RADIOSS. |

| 2. | For Input file, browse to the exercise folder and select the file GASKET_0000.rad. |

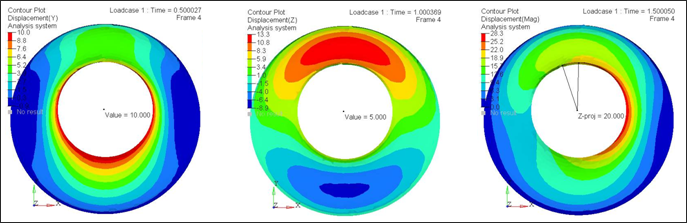

Step 14: Review the listing files for this run and verify on the results

| 1. | See if there are any warnings or errors in .out files. |

| 2. | Using HyperView plot the displacement and strain contour and vectors. |

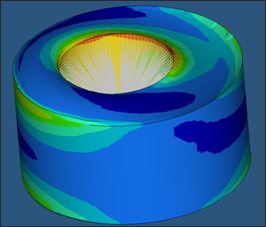

Displacement Contour for the 3 load steps (mm)

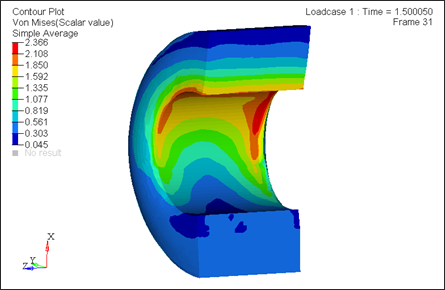

Von Mises Stress Contour at the end of the simulation

See Also: