Mesh Recommendations |

|

|

|

|

|

Mesh Recommendations |

|

|

|

|

Mesh recommendations in crash worthiness and in implicit analysis are covered.

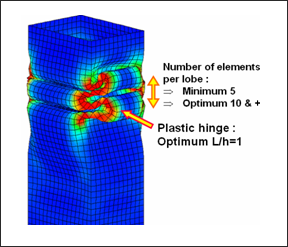

It is recommended to set a minimum of five to 10 elements in a structural working length. For buckling situation, five to 10 elements along one buckle wave length is also recommended (Fig. 2.13).

Fig. 2.13: Number of elements along a buckle wave

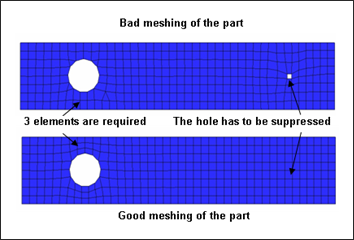

On the other hand, due to the direct relation between the size of the smallest element in the mesh and the time step, it is valuable to suppress geometry details, if they are smaller than the average size of elements (Fig. 2.14). A uniform mesh allows you to optimize time step and to ensure the consistency of the momentum transmission during shock wave propagation to avoid parasite reflections. A minimum of three elements along the width is required for better elasto-plastic behavior.

Fig. 2.14: Surface mesh generation for part with holes

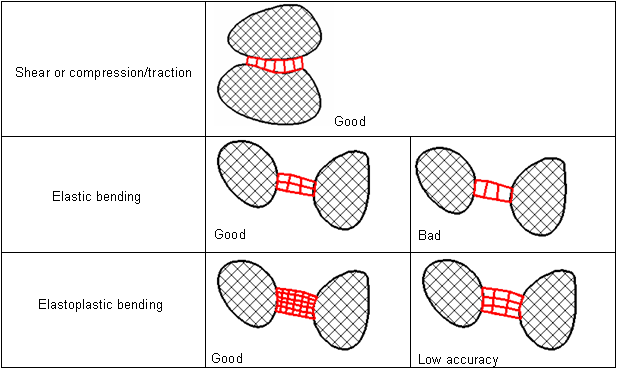

Observe the minimum number of elements, taking into account the mechanical behavior. The minimum number of elements in the width is:

| • | 1 for the parts working with quasi-uniform stress distribution as pressure and shear loading without bending |

| • | 2 for elastic behavior, including bending |

| • | 3 for low accuracy elastoplastic behavior |

| • | 5 for good accuracy elastoplastic behavior |

| • | 10 for good accuracy elastoplastic behavior, including local loading or local discontinuities |

Fig. 2.15: Minimum number of elements

It is not recommended to use different kinds of element formulation in a given physical part. Fully-integrated and under-integrated elements do not have the same stiffness matrices; but they do have the same mass matrix. The transition of momentum between these two kinds of elements may be a problem.

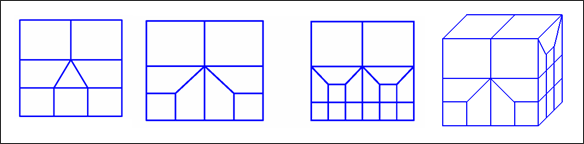

To reduce the number of triangles and to improve the consistency of the mesh, the transition patterns illustrated in Fig. 2.16 can be used.

Fig. 2.16: Mesh transition examples

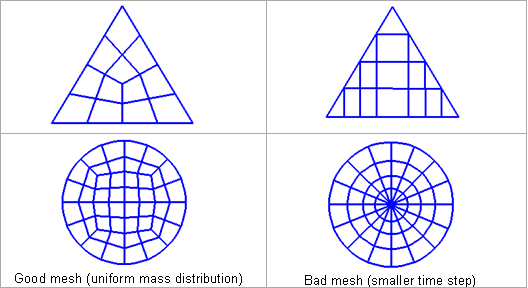

With one integration point, there are no element shapes for which the element formulation becomes completely wrong (elements with angles larger than 180 degrees are still working with bad accuracy, but without numerical problems). It is recommended to use elements as regular as possible with an angle typically between 45 and 120 degrees. The ratio between the largest and smallest edge is not critical for explicit formulation. A uniform mesh is recommended to distribute mass uniformly over the structure. It is possible to avoid triangle creation, even for a triangular geometry or a circle (Fig. 2.17).

Fig. 2.17: Mesh transition examples

In RADIOSS what kind of mesh quality given often depends on the robustness of the elements. Often, an explicit run has different exigencies than an implicit one, for example, homogeneous mesh is more important for explicit (due to time step), than implicit and positive Jacobi warpage, skewness and aspect ratio are more important for implicit (due to convergence), than explicit. Initially, getting a good mesh quality condition is necessary for a good simulation result.