Multi-Point Constraints (/MPC) |

|

|

|

|

|

Multi-Point Constraints (/MPC) |

|

|

|

|

Gear type joints are more complex than other kinematic joints. They use the Lagrange Multiplier method and are compatible with all other Lagrange Multiplier kinematic conditions and incompatible with all classical kinematic conditions.

Three examples of these joints are explained:

| • | rotational gear type joint |

| • | rack and pinion joint |

| • | differential gear joint |

Mass and inertia may be added to all nodes. MPC joints impose relations between nodes velocities. The MPC cannot be applied to the translational degrees of freedom of a node without mass or the rotational degrees of freedom of a node without inertia.

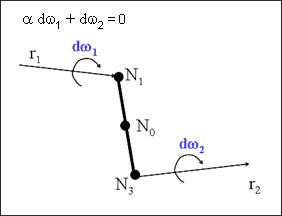

This joint is used to impose a rotational velocity relation between input and output node as:

Fig. 4.21: Rotational type joint

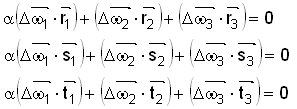

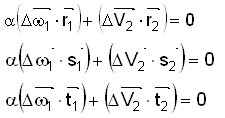

Translational velocities of gear joint nodes are constrained by a rigid link relation. For the rotational degrees of freedom, a scale factor is imposed between velocities of nodes N1 and N2, measured in their local coordinates. The corresponding constraint equations are the following:

Where, ![]() ,

, ![]() are relative rotational velocities of nodes N1 and N2 in respect of the rigid body rotational velocity.

are relative rotational velocities of nodes N1 and N2 in respect of the rigid body rotational velocity.

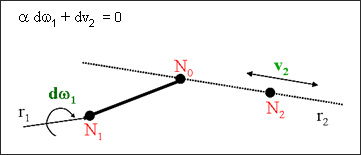

This joint allows the rotational velocity of node to be transformed to a translational velocity as:

Fig. 4.22: Rack and Pinion type joint

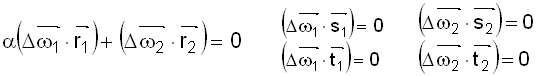

The constraint equations for these velocities are:

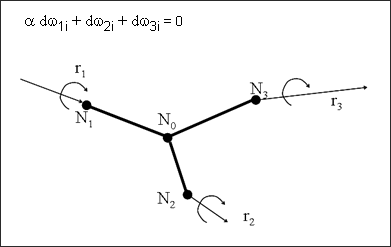

This joint is used to impose rotational velocity relations between an input node and two output nodes as:

Fig. 4.23: Differential joint type

The rotational velocities of a differential gear joint are constrained by the relations: