Modeling Errors |

|

|

|

|

|

Modeling Errors |

|

|

|

|

RBE3 using 123456 DOF coupling at the independent GRID points can produced unexpected results.

OptiStruct will issue the following warning:

*** WARNING #340

RBE3 element 6300346 has nonzero weight at rotational (456) dofs of independent grids.

This practice may result in undesirable load distribution - use with caution.

Use of very thin plate elements (.001 thickness or less) on surfaces of solid elements will produce near singularities, if MID2 and MID3 are specified on the PSHELL data. OptiStruct will issue the following warning.

*** WARNING #1265

PSHELL 10003383 has thickness 0.001 or less and bending properties defined. This can lead to matrix singularities, causing message 153.

If this element is intended to be only a membrane element, please leave MID2 and MID3 blank on the PSHELL data.

For thin skin elements, leave MID2 and MID3 blank on the PSHELL data.

Confirm that Field 9, CID is specified with either 0 (zero) or the appropriate local coordinate system on CELAS GRID points. Below is an example of the OptiStruct output for the two types of modeling errors:

For CELAS grids having different local coordinate systems.

*** WARNING # 1942

CELAS2 8820024 references GRID data with different CD.

This may constrain rigid body motion

Do not connect CBEAM or CBAR to skin elements that have MID2 and MID3 blank on the PSHELL data, as this will cause mechanisms. Use RBE2 elements instead with 123 DOFs specified.

Do not use welding methods that use MPC equations. This, in general, will give very poor rigid body modes that are not equal to zero. Use rigid elements instead.

Do not use an RBE3 using 123456 DOF on the dependent GRID to only 1 or 2 GRID points with 123456 DOF on the independent points. Use of these types of elements can produce extra rigid body modes.

If you use just on independent GRID, OptiStruct will issue the following warning:

*** WARNING #341

RBE3 element 10159308 has only two nodes.

This practice may result in undesirable load distribution - use with caution.

Use at least 3 non co-linear grid points with only 123 DOF on the independent GRID.

CELAS elements between two non-coincident points will produce poor rigid body modes. Use CBUSH elements instead. The use of GROUNDCHECK will catch misaligned CELAS elements.

Below is a list of elements that have non-zero rigid body strain energies:

These elements can cause GROUNDCHECK to FAIL

CELAS elements in this list are probably misaligned.

Elem no: 1 type: CELAS1 Six rigid mode energies and ratios:

energy - 0.000E+00 0.000E+00 0.000E+00 0.000E+00 0.000E+00 0.000E+00

ratio - 0.000E+00 0.000E+00 0.000E+00 0.000E+00 0.000E+00 4.000E+00

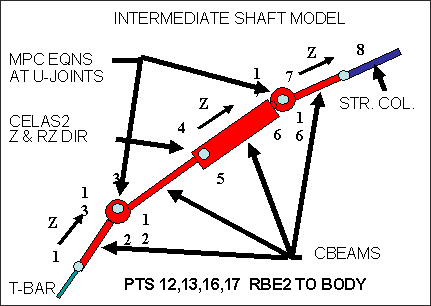

When representing torsion motion through a ball joint connection, like the intermediate shaft to steering column using MPC equations, be sure to remove the rigid body reaction from the MPC equations. Otherwise, the model will have poor rigid body modes.