The purpose of this tutorial is to demonstrate how to carry out Fluid-Structure Interaction analysis i.e., with OptiStruct nonlinear transient analysis coupling within AcuSolve fluid dynamic analysis.

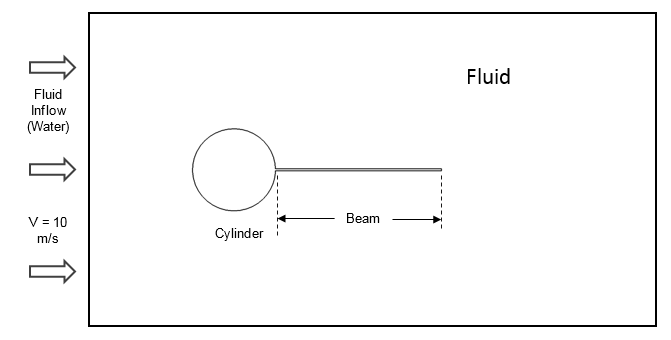

In this tutorial, you explore the possibility of using piezoelectric based fluid flow energy harvesters. These harvesters are self-excited and self-sustained in the sense that they can be used in steady uniform flows. The configuration consists of a piezoelectric cantilever beam with a cylindrical tip body (which is the structure model) which promotes sustainable, aero-elastic structural vibrations induced by vortex shedding and galloping. The structural and aerodynamic properties of the harvester alter the vibration amplitude and frequency of the piezoelectric beam and the fluid flow. As you may know, the Piezoelectric energy harvesting using fluid flow involves the mutual interaction of three distinct dynamic systems, namely the fluid, the structure and the associated electrical circuit. Note that this tutorial is limited to study only fluid and the structure domain.

Model Description

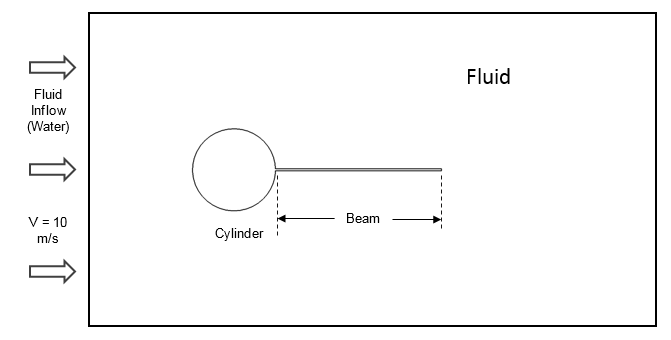

Figure 1: Schematic of the problem

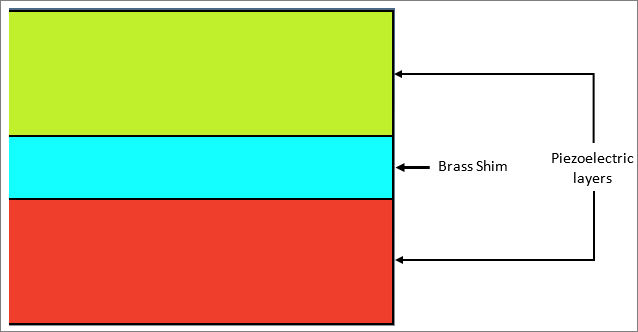

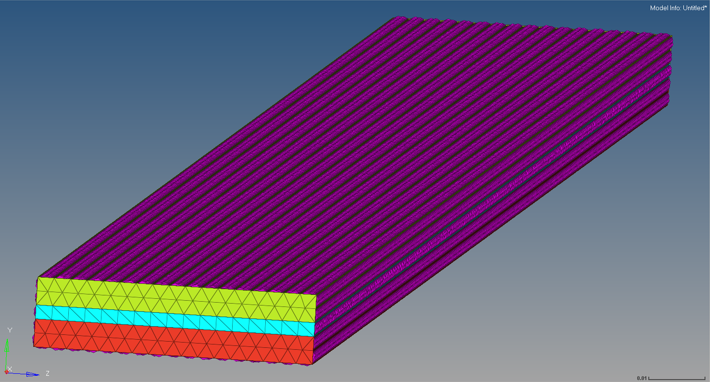

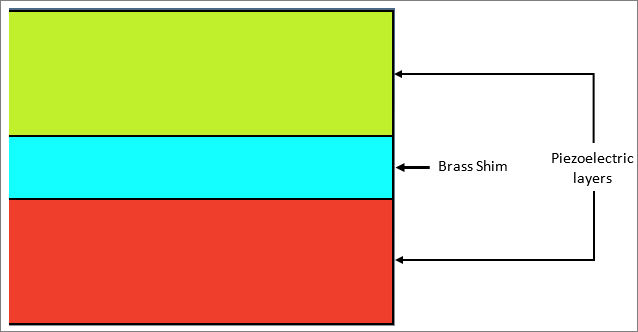

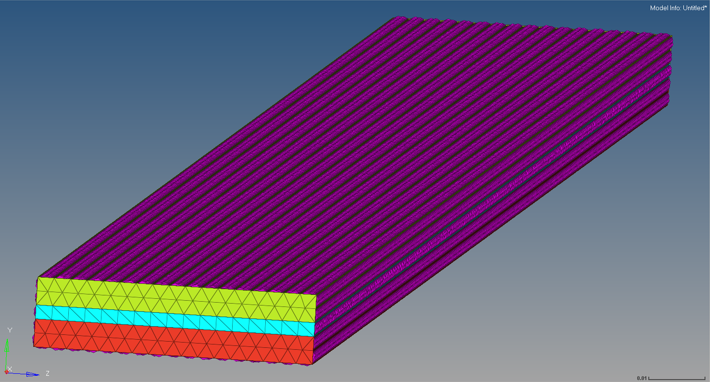

The figure below illustrates the fluid structural model used for this tutorial: the dimensions of the beam are shown in Figures 1 and 2.

The AcuSolve fluid model (slab_dcfsi.inp) and the OptiStruct structural beam model (Slab.fem) are located in the fsi_models.zip file. Refer to Accessing the Model Files.

Figure 2: Beam with its various layers

The following exercises are included in this tutorial:

| • | Set up Contact Surface, which is fluid-structure interaction surface. |

| • | Set up Nonlinear parameters, TSTEP, NLOUT and FSI cards. |

| • | Set up Nonlinear transient sub-case. |

| • | Submit job and view result |

Exercise

Step 1: Import the model

| 1. | Launch HyperMesh Desktop. The User Profiles dialog appears. |

| 2. | Select OptiStruct and click OK. This loads the user profile. |

| 3. | Click File > Import > Model. |

Step 2: Create Contact Surface

| 1. | In the Model browser, right-click and select Create > Contact Surface. |

| 2. | For Name, enter FSI_Interaction_Surf. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select SURF from the drop-down menu. |

| 5. | For Elements, click on elements and pick all the faces of the beam, as shown below. |

Tip: All sides of the beam except in the front, as shown below.

| 6. | Click add to add the faces to the contact surface. |

| 7. | Click return to exit from this panel. |

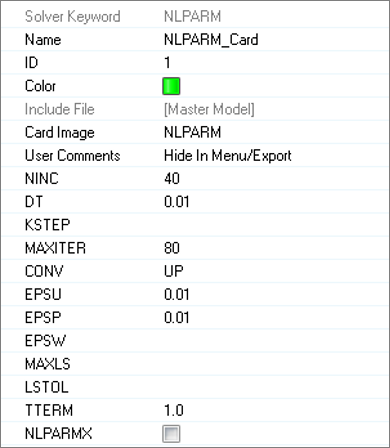

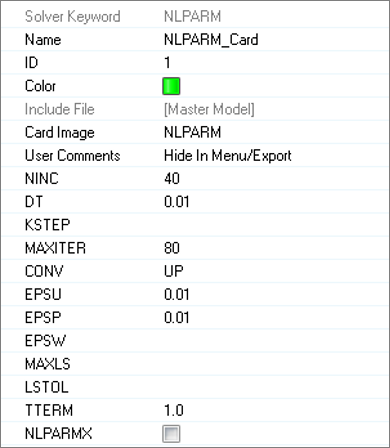

Step 3: Define Nonlinear parameters

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter NLPARM_Card. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select NLPARM from the drop-down menu. |

| 5. | Input the values, as shown below. See NLPARM Bulk Data Entry for more information. |

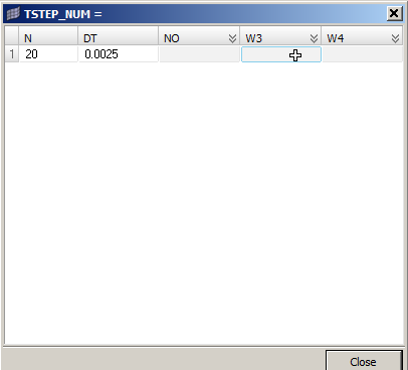

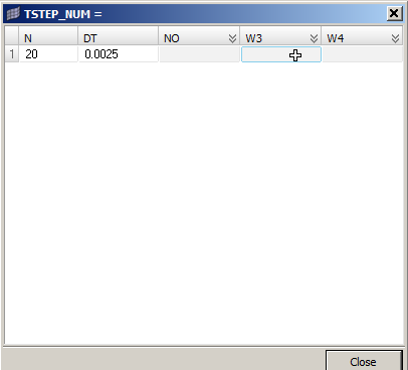

Step 4: Define Transient Time Step Parameters

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter TSTEP_Card. |

| 3. | For Card Image, select TSTEP. |

| 4. | For TSTEP NUM, enter 1. |

| 5. | Click the icon  and input the values, as shown below. See NLPARM Bulk Data Entry for more information. and input the values, as shown below. See NLPARM Bulk Data Entry for more information. |

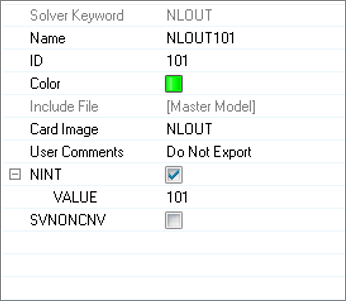

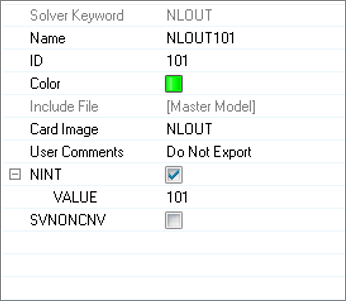

Step 5: Define incremental result output for Nonlinear Analysis

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter NLOUT101. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select NLOUT from the drop-down menu. |

| 5. | Input the values, as shown below. See NLPARM Bulk Data Entry for more information. |

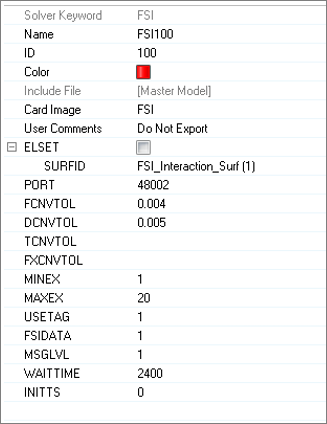

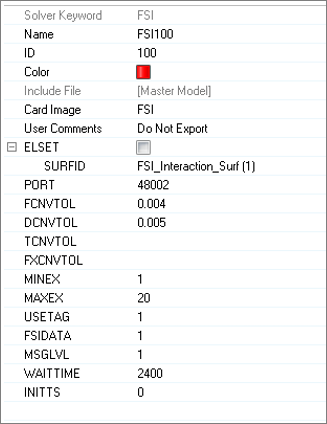

Step 6: Define Fluid-Structure Interaction Parameters

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter FSI100. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select FSI from the drop-down menu. |

| 5. | Input the values, as shown below. See NLPARM Bulk Data Entry for more information. |

Step 7: Define Output Control parameters

| 1. | From the Analysis page, select control cards. |

| 2. | Click on GLOBAL_OUTPUT_REQUEST. |

| 3. | For DISPLACEMENT, ELFORCE, OLOAD, STRESS, and STRAIN, set Option to Yes. |

| 4. | Click return twice to go to the main menu. |

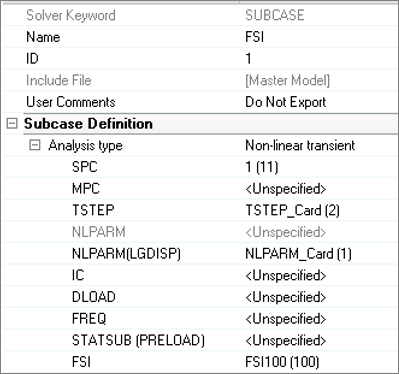

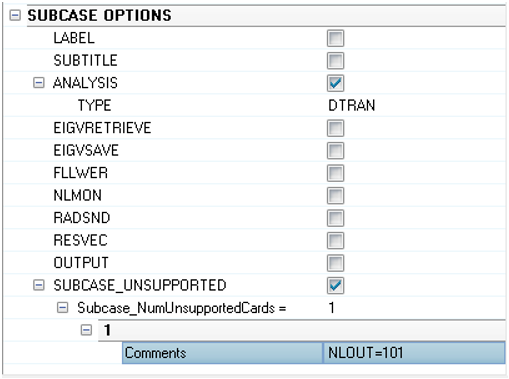

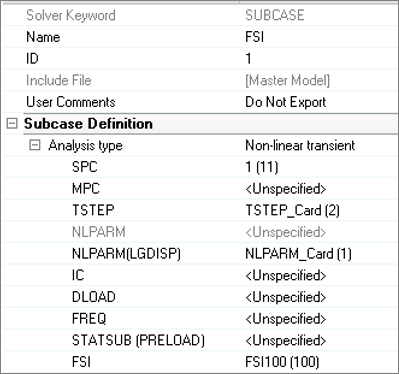

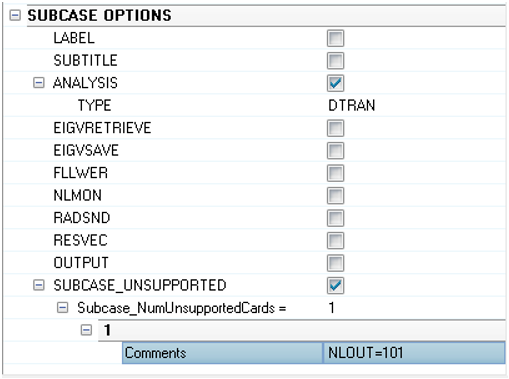

Step 8: Create Nonlinear Transient Analysis subcase

| 1. | In the Model browser, right-click and select Create > Load Step. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Analysis type, select Non-linear transient from the drop-down menu. |

| 5. | Input/Select the Load Collector, as shown below. |

| 6. | Reference the NLOUT bulk data entry as a SUBCASE_UNSUPPORTED entry as follows: |

Step 9: Export the OptiStruct Input file

| 1. | From the Analysis page, select OptiStruct. |

| 2. | Click save as and select the directory where you want to write the file. |

| 3. | For File Name, enter Slab.fem and click Save. The file extension .fem is necessary for OptiStruct to recognize it as an input file. |

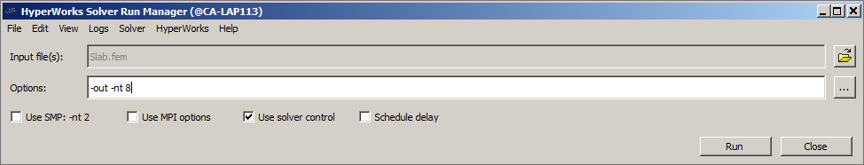

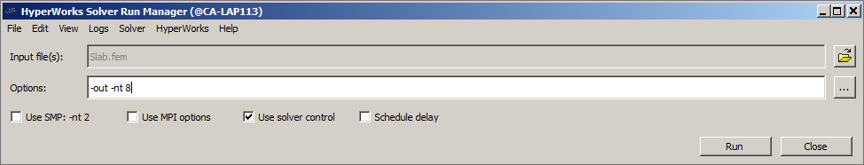

Step 10: Submit the job with HyperWorks Solver Run Manager

| 1. | Launch the HyperWorks Solver Run Manager and select the Slab.fem file. |

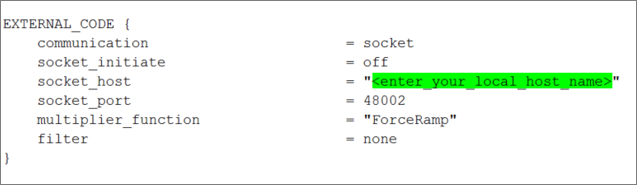

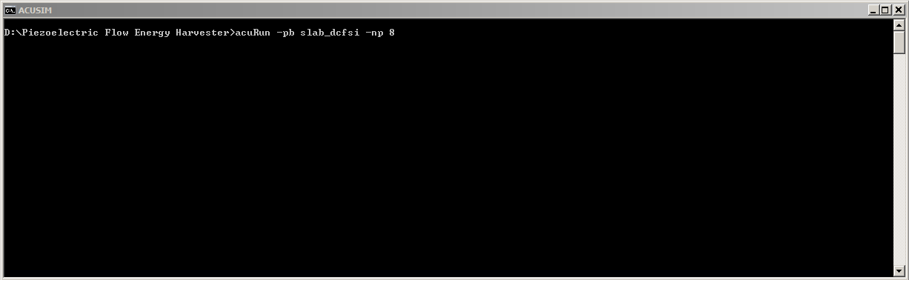

Step 11: Prepare and Submit the AcuSolve job with AcuSolve command prompt

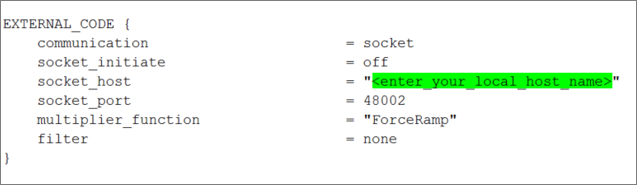

| 1. | Open the AcuSolve input file (slab_dcfsi.inp) in a text editor and change the socket_host parameter in the EXTERNAL_CODE block to your machines hostname and save the file. |

| 2. | Open the AcuSolve Cmd Prompt application and enter the command: acuRun-pb slab_dcfsi -np 8 (shown below). |

If the job is successful, you will see new results files in the directory where HyperMesh was invoked. The Slab.out file is where you will find error messages that will help you debug your input deck, if any errors are present.

The default files that will be written to your directory are:

cci.txt

|

Contains information pertaining to model progression. Logs regarding connection establishment, initial external code handshake and subsequent time step data in conjunction with exchange/stagger.

|

slab.html

|

HTML report of the analysis, giving a summary of the problem formulation and the analysis results.

|

slab.out

|

ASCII based output file of the model check run before the simulation begins and gives some basic information on the results of the run.

|

slab.stat

|

Summary of analysis process, providing CPU information for each step during the process.

|

slab.h3d

|

HyperView compressed binary results file.

|

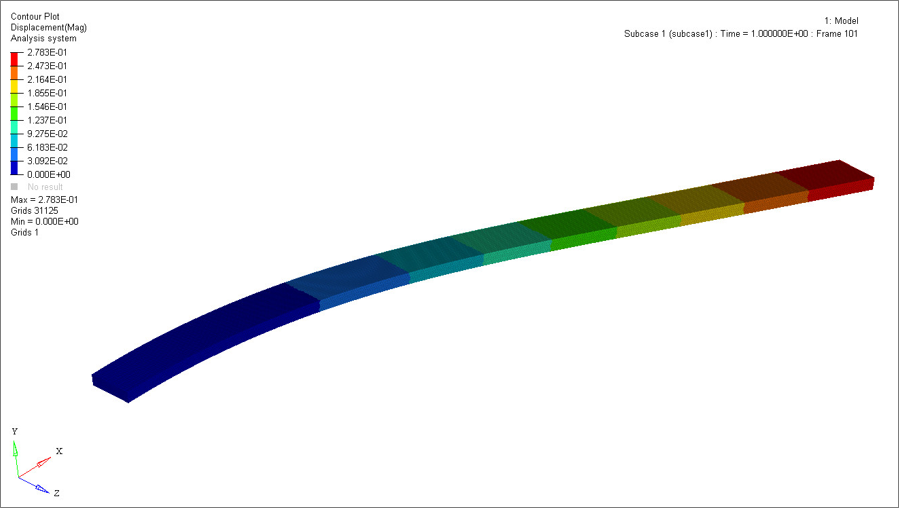

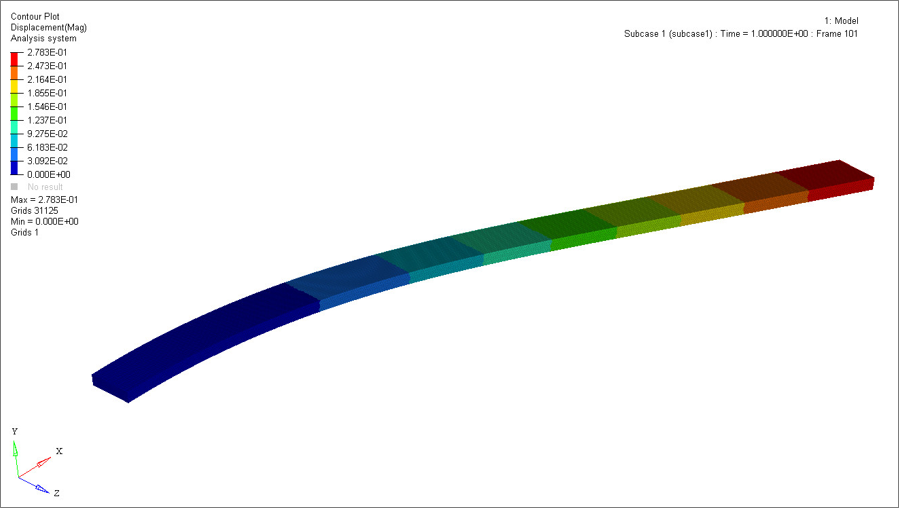

Step 12: View analysis results

| 1. | Using HyperView, plot the Displacement contour at 1.0 s. |

See Also:

OptiStruct Tutorials

Fluid-Structure Interaction