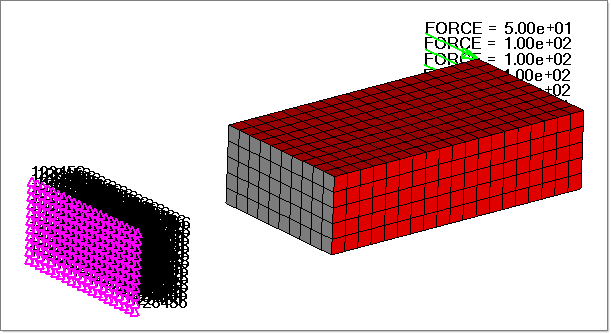

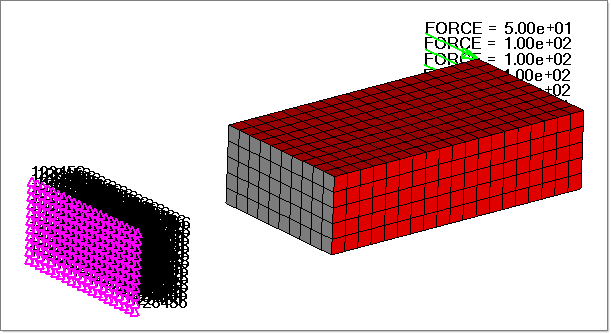

In this tutorial, an existing finite element model of a simple cantilever beam is used to demonstrate how to connect dissimilar meshes using CWELD elements.

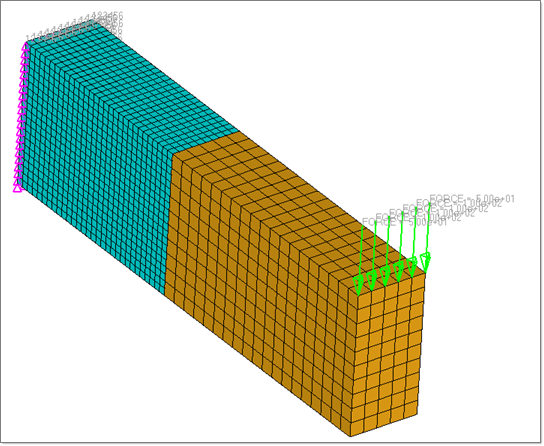

Figure 1: Cantilever beam with dissimilar meshes.

The following exercises are included:

| • | Setting up the problem in HyperMesh |

| • | Comparing results with a control example |

Exercise

Step 1: Launch HyperMesh and set the OptiStruct User Profile

| 1. | Launch HyperMesh. The User Profiles dialog appears. |

| 2. | Select OptiStruct and click OK. This loads the user profile. It includes the appropriate template, macro menu, and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct. |

| 3. | Click File > Open. An Open Model browser window opens. |

| Note: | If HyperMesh Desktop was launched, use: File > Open > Model. |

|

| 4. | Select the dissimilar.hm file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. |

| 5. | Click Open. The dissimilar.hm database is loaded into the current HyperMesh session, replacing any existing data.- 6) |

Step 2: Create membrane elements

The database contains two unconnected components: solid_fine and solid_coarse. These unconnected components are to be connected by CWELD elements using the "grid to element" option. In order to achieve this, membrane elements need to be created on the matching faces of the solid_coarse and solid_fine components.

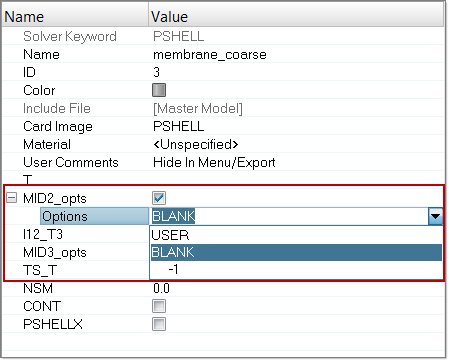

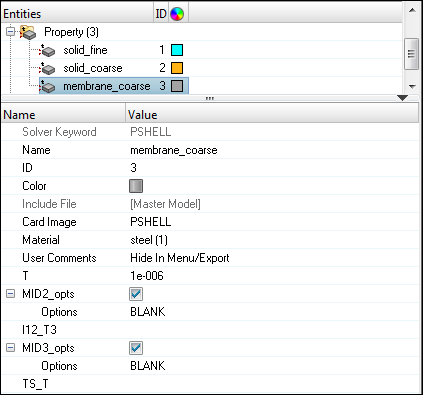

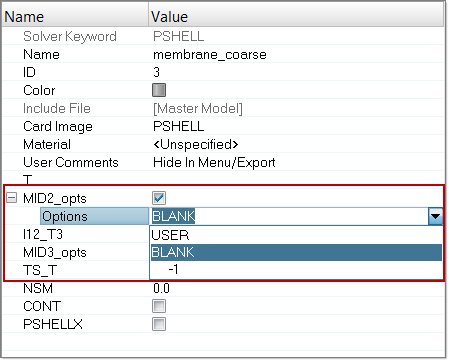

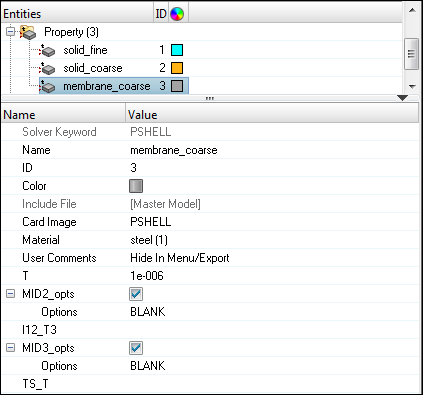

| 1. | In the Model browser, right-click and select Create > Property. A default PSHELL property template displays in the Entity Editor. |

| 2. | For Name, enter membrane_coarse. |

| 3. | For Card Image, select PSHELL from the drop-down menu. |

| 4. | For Material, click Unspecified > Material. |

| 5. | In the Select Material dialog, select steel and click OK. |

| 6. | Check the box next to MID2_opts. An option list appears beneath MID2_opts. |

| 7. | Click the switch next to USER and select BLANK from the pop-up menu. Notice the MID2 field disappears from the card image. |

| 8. | Check the box next to MID3_opts. An option list appears beneath MID3_opts. |

| 9. | Click the switch next to USER and select BLANK from the pop-up menu. Notice the MID3 field disappears from the card-image. |

| 10. | For T (thickness), enter 1E-6. |

| 11. | In the Model browser, right-click and select Create > Property. A default PSHELL property template displays in the Entity Editor. |

| 12. | For Name, enter membrane_fine. |

| 13. | Input the corresponding values for membrane_fine exactly the same as for membrane_coarse. |

| 14. | In the Model browser, right-click and select Create > Component. |

| 15. | For Name, enter membrane_coarse. |

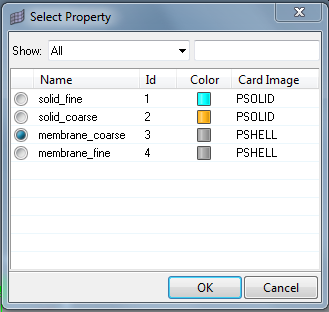

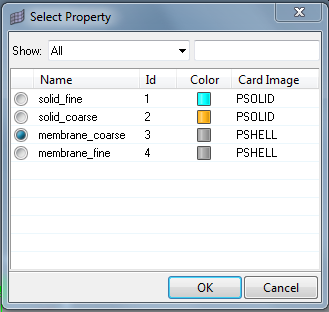

| 16. | For Property, click Unspecified > Property. |

| 17. | In the Select Propety dialog, select membrane_coarse and click OK. |

| 18. | From the Tool page, click faces. |

| 19. | Click comps, select the solid_coarse component, click select > find faces. Membrane elements are created on the faces of solid_coarse component and they appear on the graphic window. |

| 20. | In the Model browser, right-click the component ^faces and click Isolate. This displays only ^faces component. |

| 21. | From the Tool page, click organize. |

| 22. | Select only the elements that lie on the matching face. |

(Rotate the model so you can see the matching face, then, after making sure elems is selected, click on any one of the elements on the matching face. Then, click elems >> by face. This selects all the elements on the matching face).

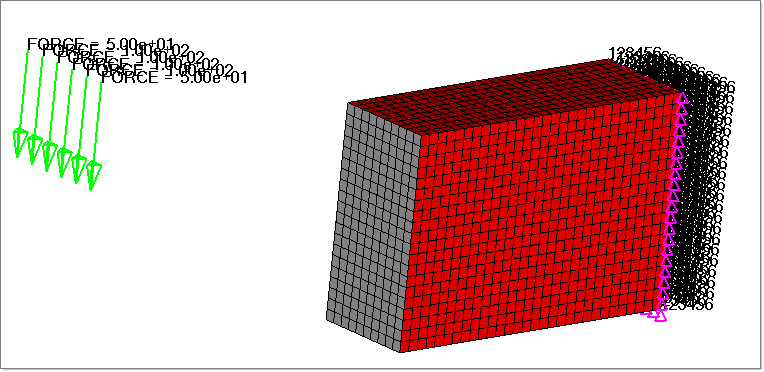

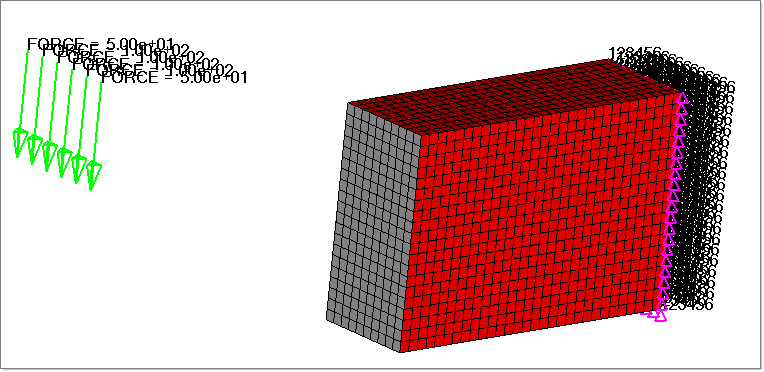

Figure 4: Selecting elements on matching face for solid_coarse component

| 23. | Click dest component = and select membrane_coarse from the list of components. |

| 24. | Click move. The elements are now part of the membrane_coarse component. |

| 26. | On the Tool page, select faces. |

| 28. | Click return to exit the panel. |

| 29. | In the Model browser, right-click and select Create > Component. |

| 30. | For Name, enter membrane_fine. |

| 31. | For Property, click Unspecified > Property. |

| 32. | In the Select Property dialog, select membrane_fine and click OK. |

| 33. | On the Tool page, select faces. |

| 34. | Click comps, select the solid_fine component, and click select > find faces. Membrane elements are created on the faces of solid_fine component and they appear on the graphics window. |

| 36. | Right-click ^faces component and click Isolate. This displays only ^faces component in the graphics window. |

| 37. | From the Tool page, select the organize panel. |

| 38. | Select only the elements that lie on the matching face as shown below. (Use a method similar to the one mentioned in Step 2.22 of this section). |

Figure 5: Selecting elements on matching face for solid fine component.

| 39. | Click dest component= and select membrane_fine from the list of components. |

| 40. | Click move. The elements are now part of the membrane_fine component. |

| 42. | From the Tool page, select the faces panel. |

| 43. | Click delete faces and click return to return to the main menu. |

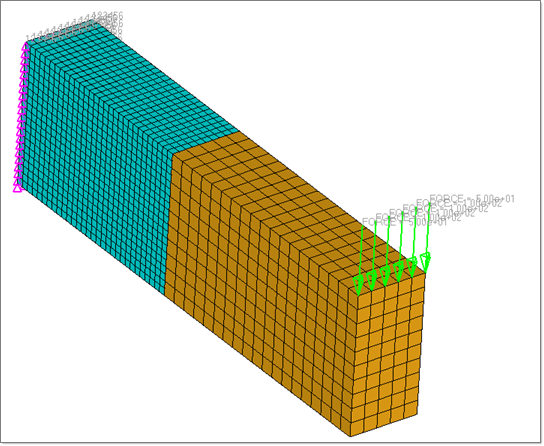

| 44. | In the Model browser, right-click and select Components > Hide. |

| 45. | Click the icon highlighted in red below to keep only the membrane elements in display. |

Figure 6: Displaying only membrane elements

Step 3: Create CWELD elements

A PWELD property must be created for the CWELD elements.

| 1. | In the Model browser, right-click and select Create > Property. A default PSHELL property template displays in the Entity Editor. |

| 3. | For Card Image, select PWELD from the drop-down menu and click Yes to confirm. |

| 4. | For Material, click Unspecified > Material. |

| 5. | In the Select Material dialog, select steel and click OK. |

| 6. | For D (weld diameter), enter 0.1. This creates a new property definition named welds. |

| 7. | In the Model browser, right-click and select Create > Component. |

| 9. | Click Color and select a color. This creates the new component named welds. |

| 10. | From the 1D page, click spotweld. |

| 11. | Make sure the using elems subpanel is selected. |

| 12. | Click elems >> displayed. |

| 13. | Click the switch under element config: and select rod from the pop-up menu. |

| 14. | Click property = and select welds from the list of properties. |

| 15. | Click search tolerance = and enter 0.1. |

| 16. | Click nodes >> by collector and select the membrane_fine collector. |

| 17. | Click create. A weld element is created at each node on the fine-mesh matching face. A number of plot elements are created too, these are helpful to find the elements attached when looking for the welds. |

| 18. | Click return to return to the main menu. |

Submitting the Job

Step 4: Save the database

| 2. | In the File name field, enter dissimilar.hm. |

Step 5: Running OptiStruct

| 1. | From the Analysis page, click OptiStruct. |

You can also get to the OptiStruct panel from the Applications menu on the toolbar.

| 2. | Click save as and select the directory where you would like to write the OptiStruct model file, enter the file name dissimilar.fem, and click Save. |

| 3. | Set the export options: toggle to all. |

| 4. | Set the run options: toggle to analysis. |

| 5. | Set the memory options: toggle to memory default. |

| 6. | Click OptiStruct. This launches the OptiStruct job. |

If the job is successful, new results files can be seen in the directory where the OptiStruct model file was written. The dissimilar.out file is a good place to look for error messages that will help to debug the input deck if any errors are present.

The default files written to the directory are:

dissimilar.html

|

HTML report of the analysis, giving a summary of the problem formulation and the analysis results.

|

dissimilar.out

|

OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for each of the optimization iterations, and compute time information. Review this file for warnings and errors.

|

dissimilar.h3d

|

HyperView binary results file.

|

dissimilar.stat

|

Summary of analysis process, providing CPU information for each step during analysis process.

|

Post Processing Analysis Results using HyperView

Step 6: View displacement contour

| 1. | When the message Process completed successfully is received in the command window, close the window. |

| 2. | In the OptiStruct panel, click HyperView. This loads the results for the current run into HyperView. |

| 3. | Set the animation type to Linear  . . |

| 4. | Click the Contour icon  . . |

| 5. | Select the first pull-down menu below Result type: and select Displacement (v). |

| 6. | Click Apply. The resulting colors represent the displacement field resulting from the applied loads and boundary conditions. |

| 7. | Click the Page Layout icon  on the toolbar. on the toolbar. |

| 8. | Choose the second layout in the first row of the pop-up window. This changes the graphic area in two separate windows. The left window will have the previously loaded model and the right window will be blank. Load the control example in the right side window to compare the results. |

| 9. | Click the right-hand pane in the display area. A blue line appears around the window to show that it is selected. |

| 10. | Click the Load Result icon  in the toolbar. in the toolbar. |

| 11. | Click Load Model  and select the file control.h3d you saved to your working directory from the optistruct.zip file as both the model and results file. and select the file control.h3d you saved to your working directory from the optistruct.zip file as both the model and results file. |

| 13. | Right-click on the left pane and activate menu over Apply Style To > Current Page > All Selected. This option applies results from the current window to the new window. |

You can now visually compare the displacement results from the dissimilar mesh model with a uniform mesh model.

Step 7: View von Mises Stress results

| 1. | Select the left-hand panel in the display area. |

| 2. | Click  to open the panel. to open the panel. |

| 3. | Under Result type:, select Element Stresses (2D & 3D)(t) and vonMises. |

| 4. | In the field below Averaging method:, select None. |

| 6. | Right-click on the left pane and activate menu over Apply Style To > Current Page > All Selected. |

You can now visually compare the von Mises stress results from the dissimilar model with a uniform mesh model.

See Also:

OptiStruct Tutorials