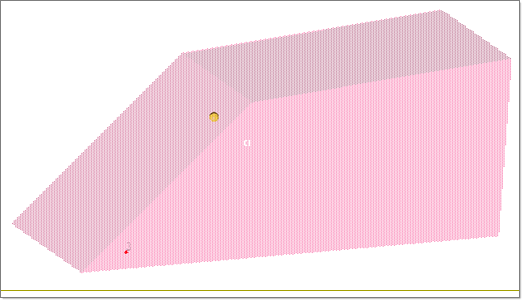

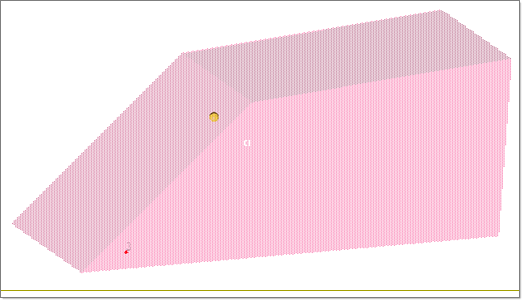

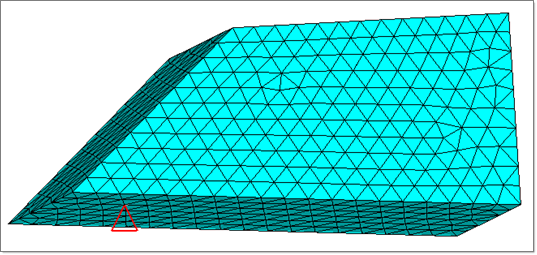

The purpose of this tutorial is to evaluate the vibration characteristics of a half car model subjected to Fluid – Structure interaction. The fluid that is being referred to is air. Essentially, the noise level or the sound level is evaluated inside the car at a location near the ear of the driver which is the main response location inside the fluid (shown below).

Half Car Model

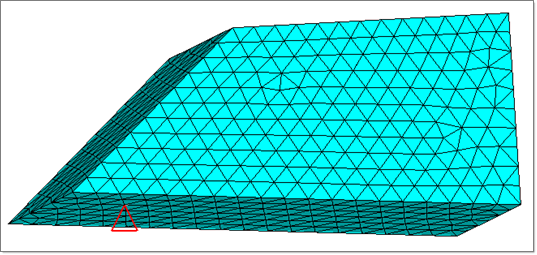

The half car model is excited at the bottom of the car, as shown by a red constraint symbol (triangle) in the above figure. The excitation provided is with the application of a unit load along the direction of the height of the car (Z-axis).

Process Overview

| • | Retrieve the HyperMesh model |

| • | Create material and geometric properties |

| • | Create modal frequency response subcase in order to perform acoustic analysis |

| • | Perform the finite element analysis and view the results |

Exercise

Step 1: Launch HyperMesh, set the OptiStruct User Profile and retrieve the file

| 2. | Select OptiStruct in the User Profiles dialog. |

| 3. | Click OK. This loads the user profile. It includes the appropriate template, macro menu and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct. |

| 4. | Click File > Open. An Open file browser opens. |

| Note: | If HyperMesh Desktop was launched, use: File > Open > Model. |

|

| 5. | Select the Half_Car.hm file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. |

Step 2: Create isotropic and fluid materials and properties and assign them to their structural and fluid elements

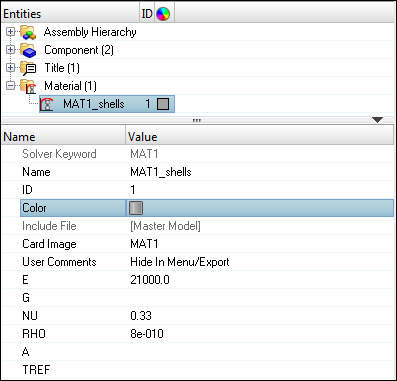

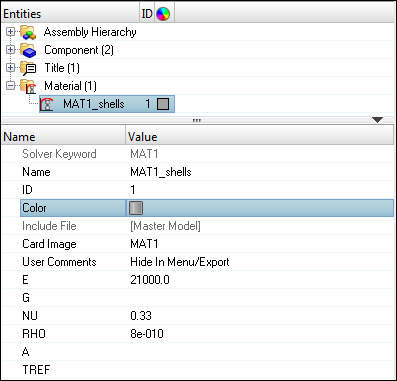

| 1. | In the Model browser, right-click and select Create > Material. |

| 2. | For Name, enter MAT1_shells. |

| 3. | For Card Image, select MAT1 from the drop-down menu. |

| 4. | Fill in the fields for E, Nu and Rho respectively as 2.1e04, 0.33 and 8.0e-10. |

| 5. | In the Model browser, right-click and select Create > Material. |

| 6. | For Name, enter MAT10_Solids. |

| 7. | For Card Image, select MAT10 from the drop-down list. |

| 8. | Fill in the fields for Rho and C respectively as 1.2e-13 and 3.4e5. |

| 9. | In the Model browser, right-click and select Create > Property. |

| 10. | For Name, enter Shells. |

| 11. | For Card Image, select PSHELL from the drop-down menu. |

| 12. | For Material, click Unspecified > Material. |

| 13. | In the Select Material dialog, select MAT1_shells from the list of materials and click OK to complete the selection. |

| 14. | Enter the thickness for the shell component by clicking T, and entering 2.0. |

| 15. | In the Model browser, right-click and select Create > Property. |

| 16. | For Name, enter Solids. |

| 17. | For Card Image, select PSOLID from the drop-down menu. |

| 18. | For Material, click Unspecified > Material. |

| 19. | In the Select Material dialog, select MAT10_Solids. |

| 20. | For FCTN, select PFLUID. |

| 21. | Click on the fluid component, the component entry is displayed in the Entity Editor. |

| 22. | For Property, click Unspecified > Property. |

| 23. | In the Select Property dialog, select the property solids. |

| 24. | Click on the structure component, the component entry is displayed in the Entity Editor. |

| 25. | For Property, click Unspecified > Property. |

| 26. | In the Select Property dialog, select the property shells. |

Step 3: Apply Loads and Boundary Conditions to the Model

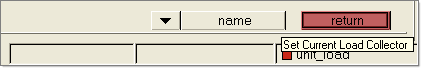

In the following steps, the model is unconstrained and a unit vertical load is applied acting upwards in the positive z-direction at a point on the base of the car (shown in page 1). The model can be unconstrained as the solver applies PARAM, INREL -2 by default to avoid the model from experiencing a rigid body motion.

First, the load collector (unit-load) is created.

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter unit-load. |

| 3. | Click Color and select a color from the color palette. |

| 4. | Leave the Card Image set to None. |

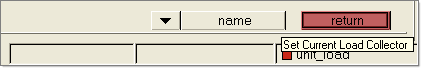

| 5. | Make sure the current load collector is set to unit_load by clicking the Set Current Load Collector field at the bottom right corner on HyperMesh window. |

This opens a panel that displays the list of load collectors.

| 6. | Click unit-load > return. |

Step 4: Create a Unit Load at a Point on the bottom of the car

| 1. | From the Analysis page, click constraints. |

| 2. | Select the create subpanel using the radio buttons on the left-hand side of the panel. |

| 3. | Select node number 19072 on the car model by clicking nodes >> by id. |

| 4. | Uncheck all dofs, except dof3 and click the = to the right of dof3 and enter a value of 1. |

| 5. | For Load Types =, select DAREA from the extended entity selection menu. |

| 6. | Click create. This applies a unit load to the selected node. |

Step 5: Create a Frequency Range Table

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter tabled1. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select TABLED1 from the drop-down menu. |

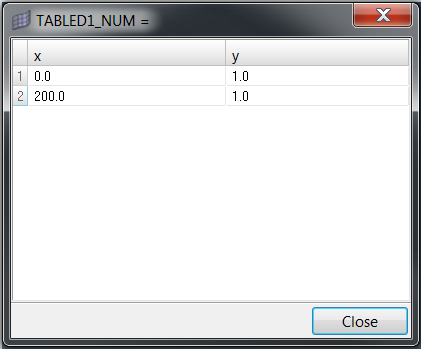

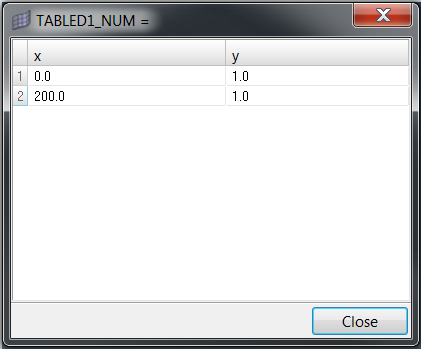

| 5. | For TABLED1_NUM, enter a value of 2, press enter. |

| 6. | Click the Table icon  next to Data field and enter x(1) = 0.0, y(1) = 1.0, x(2) = 200.0 and y(2) = 1.0 in the pop-out window. next to Data field and enter x(1) = 0.0, y(1) = 1.0, x(2) = 200.0 and y(2) = 1.0 in the pop-out window. |

This provides a frequency range of 0.0 to 200.0 with a constant 1.0 over this range and it would appear, as shown below on the GUI.

Step 6: Create a Frequency Dependent Dynamic Load

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter rload1. |

| 3. | Click Color and select a color from the color palette. |

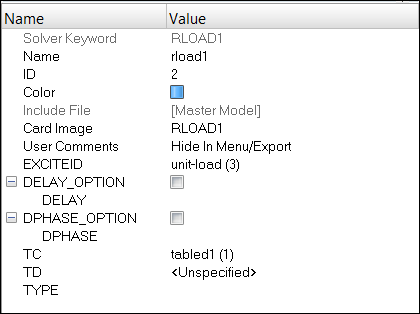

| 4. | For Card Image, select RLOAD1 from the drop-down menu. |

| 5. | For EXCITEID, click Unspecified > Loadcol. |

| 6. | In the Select Loadcol dialog, select unit-load from the list of load collectors and click OK to complete the selection. |

| 7. | Similarly select the load collector tabled1 for the TC field. |

The type of excitation can be an applied load (force or moment), an enforced displacement, velocity, or acceleration. The field TYPE in the RLOAD1 card image defines the type of load. The type is set to applied load by default.

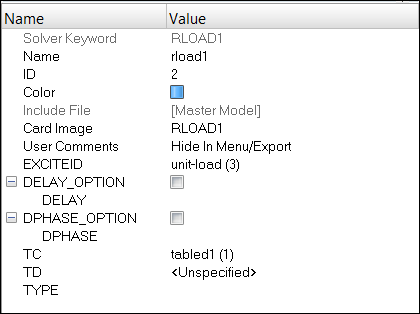

A typical RLOAD1 card appears, as shown below.

Step 7: Create a Set of Frequencies to be used in the Response Solution

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select FREQi from the drop-down menu. |

| 5. | Check the box next to FREQ1. |

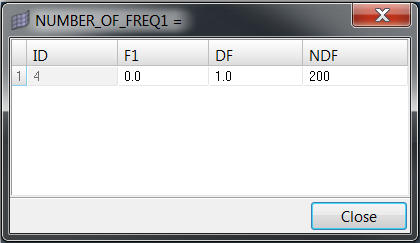

| 6. | For NUMBER_OF_FREQ1, enter a value of 1, press enter. |

| 7. | Click  next to the Data field and enter, F1= 0.0, DF= 1.0,and NDF= 200. next to the Data field and enter, F1= 0.0, DF= 1.0,and NDF= 200. |

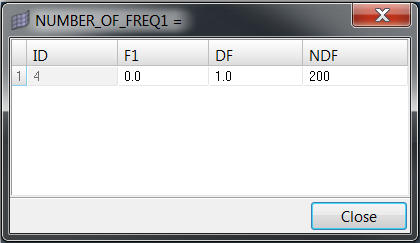

This provides a set of frequencies beginning with 0.0, incremented by 1.0 and 200 frequencies increments and the card appears as shown below on the GUI.

Step 8: Create the modal method for eigenvalue analysis using the Lanczos method and specify the frequency range for eigenvalue extraction

| 1. | In the Model browser, right-click and select Create > Load Collector. |

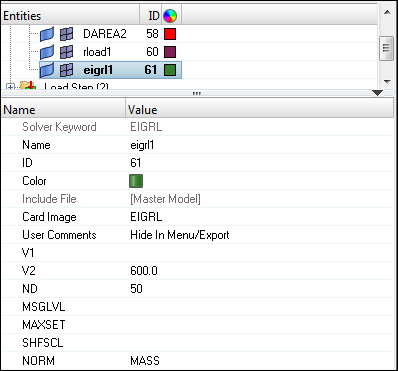

| 2. | For Name, enter eigrl1. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select EIGRL from the drop-down menu. |

| 5. | For V2, enter a value of 600.0. |

| 6. | For ND, enter a value of 50. |

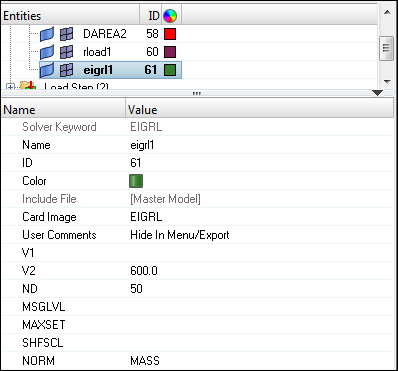

This specifies a range of frequency between an initial frequency and 600 Hz for eigenvalue extraction using the Lanczos method.

| 7. | Similarly, follow steps 8.1 to 8.6 to create another load collector named eigrl2. |

Step 9: Create an OptiStruct Loadstep

| 1. | In the Model browser, right-click and select Create > Load Step. |

| 2. | For Name, enter subcase1. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Analysis type, select Freq.resp (modal) from the drop-down menu. |

| 5. | For METHOD(STRUCT), select eigrl1 from the list of load collectors. |

| 6. | For METHOD(FLUID), select eigrl2 from the list of load collectors. |

| 7. | For DLOAD, select rload1 from the list of load collectors. |

| 8. | For FREQ, select freq1 from the list of load collectors. |

An OptiStruct subcase has been created which references the constraints, the unit load in the load collector rload1 with a set of frequencies defined in load collector freq1 and modal method defined in the load collector eigrl.

Step 10: Create a node set for output of results

| 1. | In the Model browser, right-click and select Create > Set. |

| 3. | For Card Image, select None from the drop-down menu. |

| 4. | Leave the Set Type switch set to non-ordered type. |

| 5. | For Entity IDs, click the yellow Nodes panel and select nodes with ID 18881. |

Step 11: Create a set of outputs specific to frequency response analysis

| 1. | From the Analysis page, click control cards. |

This defines the model parameters for fluid-structure interface.

| 3. | Click [INTER] and select DIFF. |

| 4. | Click [INFOR] and select ALL. |

| 5. | Click return to exit this menu. |

| 6. | Select GLOBAL_OUTPUT_REQUEST. Then check the box to the left of DISPLACEMENT. A new window appears in the work area screen. |

| 7. | Click the field box FORM and select PHASE from the pop-up menu. |

| 8. | Click the field box OPTION and select SID from the pop-up menu. A new field appears in yellow. |

| 9. | Double-click the yellow SID box and select SETA from the pop-up selection on the bottom left corner. A value of 1 now appears below the SID field box. This sets the output for only the nodes in set 1. |

| 10. | Click return to exit this menu. |

| 11. | Select GLOBAL_CASE_CONTROL. |

| 12. | Check the box next to FREQ. |

| 13. | Click FREQ and select the load collector freq1. |

| 14. | Click return to exit this menu and click next. |

| 15. | Select the OUTPUT subpanel. A new window appears in the work area. |

| 16. | Specify number of outputs = 4. |

| 17. | Verify KEYWORD is set to HGFREQ. |

Using HGFREQ results in a frequency output presentation for HyperGraph.

| 18. | Double-click on the box beneath FREQ and select ALL from the pop-up selection. |

Choosing ALL outputs results for all frequencies.

| 19. | Verify KEYWORD is set to OPTI. |

| 20. | Double-click on the box beneath FREQ and select ALL from the pop-up selection. |

| 21. | Similarly under KEYWORD select PUNCH and H3D. |

| 22. | Click return to exit this menu. |

| 25. | Scroll down and check the box next to G. A new window appears in the work area screen. |

| 26. | Click below G_V1, and input a value of 0.06 into the field box. |

This value specifies a uniform structural damping coefficient and is obtained by multiplying the critical damping [C/C0] ratio by 2.0.

| 27. | Check the box next to GFL. |

| 28. | Click below [VALUE] and enter 0.12. |

| 29. | Click return to exit the PARAM menu. |

| 30. | Click return to exit the control cards menu. |

Submitting the Job

Step 12: Submit the Job

| 1. | Click Applications > OptiStruct. |

| 2. | Following the input file: field text box and click save as. |

| 3. | Select the directory where you would like to write the OptiStruct model file, enter the name Half_car.fem in the File name: field, and click Save. |

| 4. | Set the run options: toggle to analysis. |

| 5. | Click OptiStruct. This launches the OptiStruct job. |

If the job is successful, new results files can be seen in the directory where the OptiStruct model file was written. The Half_car.out file is a good place to look for error messages that will help to debug the input deck if any errors are present.

The default files written to the directory are:

Half_car.html

|

HTML report of the analysis, giving a summary of the problem formulation and the analysis results.

|

Half_car.out

|

OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for all optimization iterations, and compute time information. Review this file for warnings and errors.

|

Half_car.h3d

|

HyperView binary results file.

|

Half_car.stat

|

Summary of analysis process, providing CPU information for each step during analysis process.

|

Review the Results (HyperMesh and HyperGraph)

Step 13: Review the results

This step describes how to view displacement results (.mvw file) in HyperGraph. The HyperView results file (.h3d) contains only the displacement results for the node specified in the node set output.

| 1. | When the analysis process completes, click HyperView to open a HyperView session. |

| 2. | Close the Message log menu, if one appears, by clicking Close. |

| 3. | In the HyperView window, click File > Open > Session. An Open Session File window opens. |

| 4. | Select the directory where the job was run and select the file Half_Car_freq.mvw. |

| 5. | Click Open. A discard warning appears. |

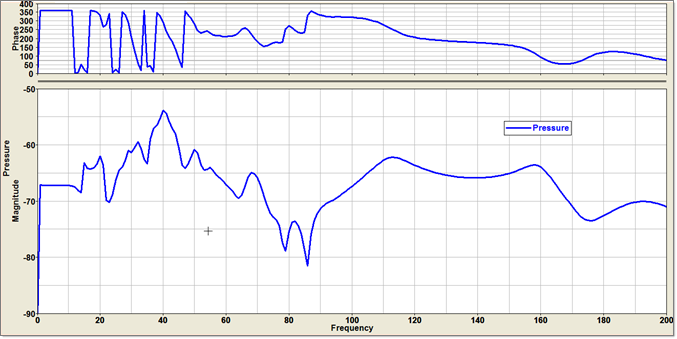

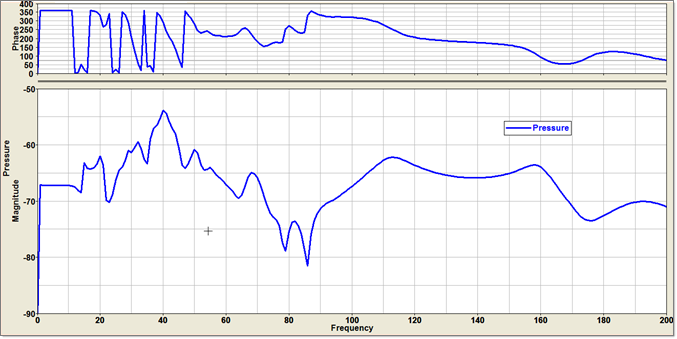

Two graphs per page and a total of one page are displayed in HyperGraph. The graph title shows Subcase 1 (subcase 1) pressure at grid 18881.

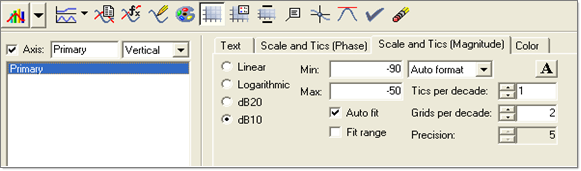

| 7. | Click the Axis toolbar icon  . . |

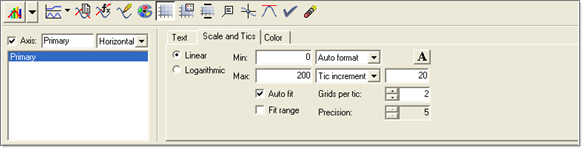

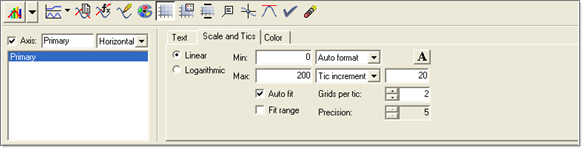

| 8. | Make sure the Axis is set to Primary and Horizontal. |

| 9. | Click the Scale and Tics tab. |

| 10. | Make sure the toggle is set to Linear. |

| 11. | In the Axis, toggle from Horizontal to Vertical. |

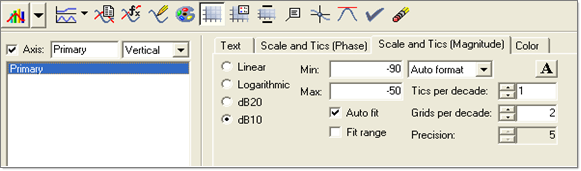

| 12. | Click on the Scale and Tics (Magnitude) tab. |

| 13. | Make sure the toggle is set to dB10. |

There are two sets of results on this page. The top graph shows Phase Angle verses Frequency (log). The bottom graph shows Magnitude verses Frequency (log) (see figure below) for Pressure at grid 18881.

This concludes the HyperGraph results processing.

See Also:

OptiStruct Tutorials