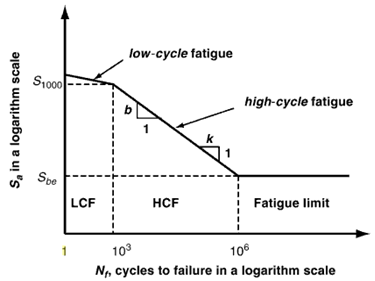

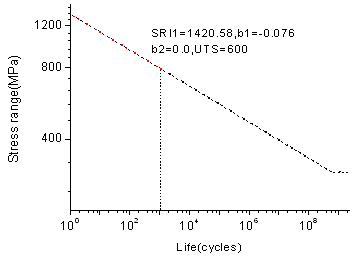

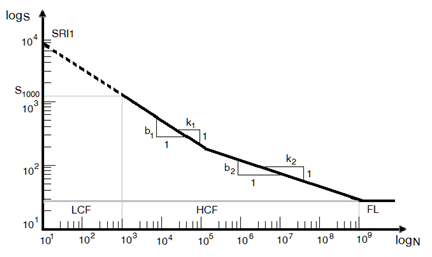

OptiStruct uses the S-N approach for calculating the fatigue life. The S-N approach is suitable for high cycle fatigue, where the material is subject to cyclical stresses that are predominantly within the elastic range. Structures under such stress ranges should typically survive more than 1000 cycles.

The S-N approach is based on elastic cyclic loading, inferring that the S-N curve should be confined to numbers greater than 1000 cycles. This ensures that no significant plasticity is occurring. This is commonly referred to as high-cycle fatigue.

Figure 1: Low Cycle and High Cycle regions on the S-N curve

Since S-N theory deals with uniaxial stress, the stress components need to be resolved into one combined value for each calculation point, at each time step, and then used as equivalent nominal stress applied on the S-N curve.

In OptiStruct, various stress combination types are available with the default being “Absolute maximum principle stress”. In general “Absolute maximum principle stress” is recommended for brittle materials, while “Signed von Mises stress” is recommended for ductile material. The sign on the signed parameters is taken from the sign of the Maximum Absolute Principal value.

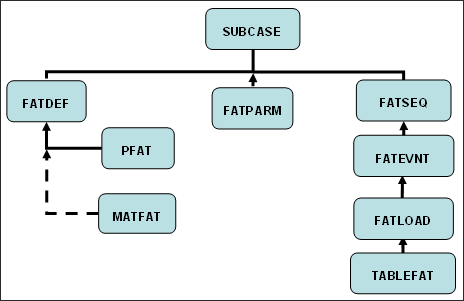

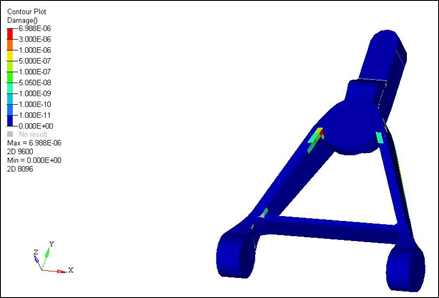

A flowchart of the fatigue setup in HyperMesh can be described as shown in the image below.

Figure 2: Fatigue analysis flowchart.

The three aspects to the fatigue definition are the fatigue material properties, the fatigue parameters and the loading sequence and event definitions.

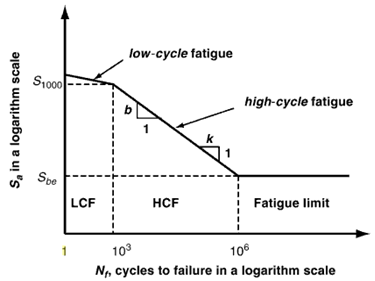

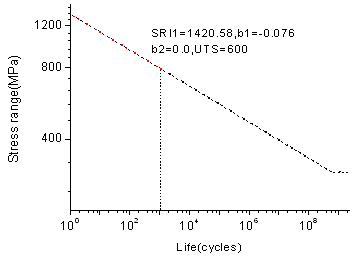

The fatigue material properties: (S-N curve)

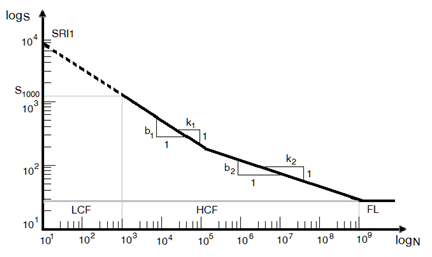

Figure 3: Two segment S-N curve

FATDEF: Defines the elements and associated fatigue properties that will be used for the fatigue analysis.

PFAT: Defines the finish, treatment, layer and the fatigue strength reduction factors for the elements.

MATFAT: Defines the material properties for the fatigue analysis. These properties should be obtained from the material’s S-N curve (Figure 3). The S-N curve, typically, is obtained from completely reversed bending on mirror polished specimen. S-N curves can be one segment or two segments.

The fatigue parameters

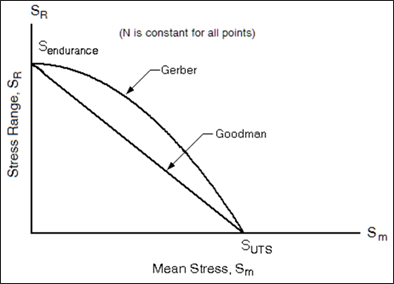

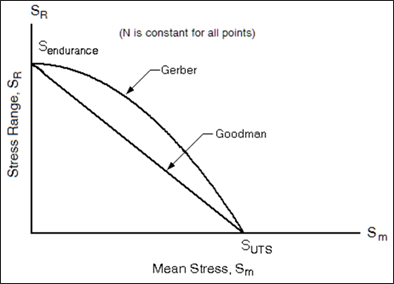

Figure 4: Mean Stress correction

FATPARM: Defines the parameters for the fatigue analysis. These include stress combination method, mean stress correction method (Figure 4), Rainflow parameters, Stress Units.

The fatigue sequence and event definition

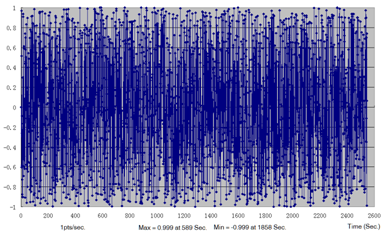

Figure 5: Load Time History

FATSEQ: Defines the loading sequence for the fatigue analysis. This card can refer to another FATSEQ card or a FATEVNT card.

FATEVNT: Defines loading events for the fatigue analysis.

FATLOAD: Defines fatigue loading parameters.

The following files found in the optistruct.zip file are needed to perform this tutorial. Refer to Accessing the Model Files.

ctrlarm.fem, load1.csv and load2.csv

Exercise

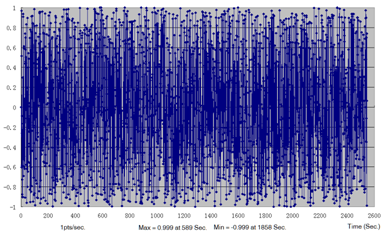

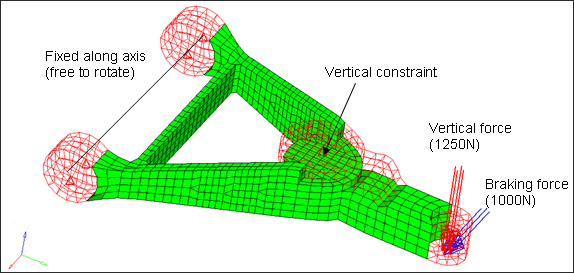

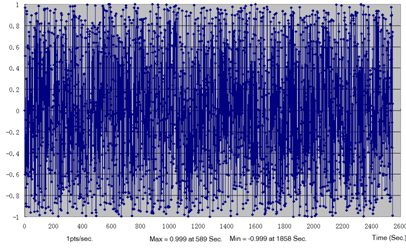

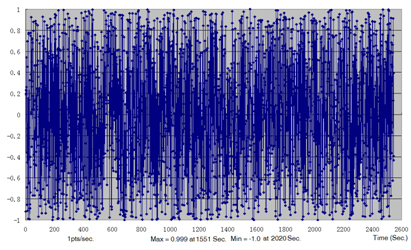

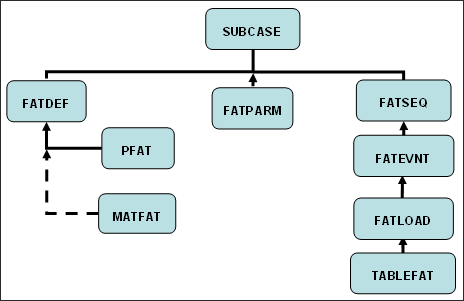

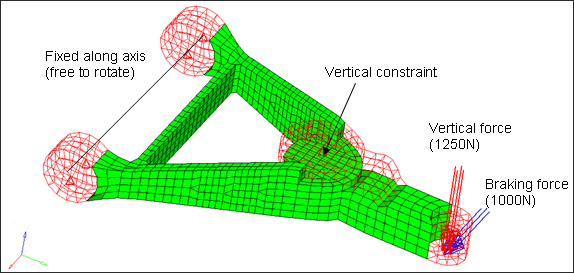

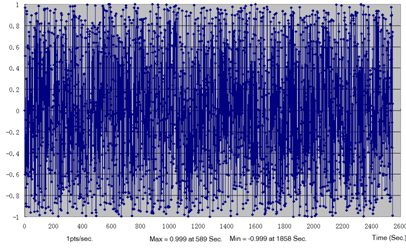

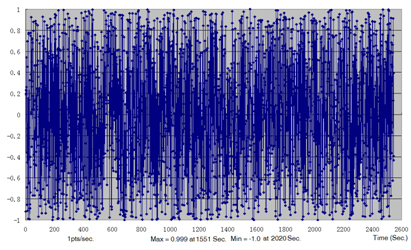

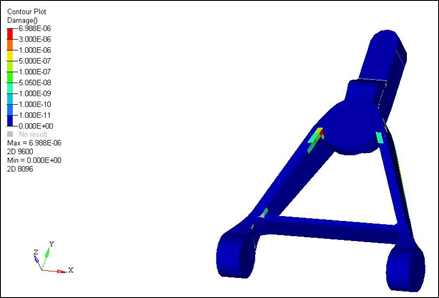

In this tutorial, a control arm loaded by brake force and vertical force is used, as shown in Figure 6. Two load time histories acquired for 2545 seconds with 1 HZ, shown in Figure 7(a) and 7(b), are adopted. The SN curve of the material used in the control arm is shown in Figure 8. Because a crack always initiates from the surface, a skin meshed with shell elements is designed to cover the solid elements, which can improve the accuracy of calculation as well.

Figure 6: Model of the control arm for fatigue analysis

(a)

(b)

Figure 7: Load time history (a) for vertical force (b) for braking force

Figure 8: SN curve

Step 1: Load and review the model

The model being used for this exercise is that of a control arm, as shown in Figure 6. Loads and boundary conditions and two static loadcases have already been defined on this model.

| 2. | Select OptiStruct in the User Profiles dialog. |

| 3. | Import the ctrlarm.fem file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. |

Step 2: Define TABFAT cards

The first step in defining the loading sequence is to define the TABFAT cards. This card represents the loading history.

| 1. | Make sure the Utility menu is selected in the View menu. Click View > Browsers > HyperMesh > Utility. |

| 2. | Click on the Utility tab beside the Model tab in the browser. In the Tools section, click on TABLE Create. |

| 3. | Set Options: to Import table. |

| 6. | Browse for the loading file. |

| 7. | In the Open the XY data File dialog box, set the Files of type filter to CSV (*.csv). |

| 8. | Open the load1.csv file you saved to your working directory from the optistruct.zip file. Refer to Accessing the Model Files. |

| 9. | Create New Table with Name: table1. |

| 10. | Click Apply to save the table. The load collector “table1” with TABFAT card image is created. |

| 11. | Browse for a second loading file load2.csv. |

| 12. | Create New Table with Name: table2. |

| 13. | Click Apply to save the table. The load collector “table2” with TABFAT card image is created. |

| 14. | Exit from the Import TABFAT window. |

Tables appear under Load Collector in the Model browser.

| Note: | A file in DAC format can very easily be imported in Altair HyperGraph and converted to CSV format to be read in HyperMesh. |

|

Step 3: Defining FATLOAD cards

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter FATLOAD1. |

| 3. | Click Color and select a color from the color palette. |

| 4. | For Card Image, select FATLOAD from the drop-down menu. |

| 5. | For TID (table ID), select table1 from the list of load collectors. |

| 6. | For LCID (load case ID), select SUBCASE1 from the list of load steps. |

| 7. | Set LDM (load magnitude) to 1. |

| 9. | Repeat the process to create another load collector named FATLOAD2 with FATLOAD as card image and pointing to table2 and SUBCASE2. |

| 10. | Set LDM to 1 and Scale to 3.0. |

Step 4: Defining FATEVNT card

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter FATEVENT,. |

| 3. | For Card Image, select FATEVNT. |

| 4. | Set FATEVNT_NUM_FLOAD to 2. |

| 5. | Click on the Table icon  next to the Data field and select FATLOAD1 for FLOAD(1) and FATLOAD2 for FLOAD(2) in the pop-out window. next to the Data field and select FATLOAD1 for FLOAD(1) and FATLOAD2 for FLOAD(2) in the pop-out window. |

Step 5: Defining the FATSEQ card

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter FATSEQ. |

| 3. | For Card Image, select FATSEQ. |

| 4. | For FID (Fatigue Event Definition), select FATEVENT from the list of load collectors. |

Defining the sequence of events for the fatigue analysis is completed. The Fatigue parameters are defined next.

Step 6: Defining the Fatigue parameters

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter fatparam,. |

| 3. | For Card Image, select FATPARM. |

| 4. | Make sure TYPE is set to SN. |

| 5. | Set STRESS COMBINE to SGVON (Signed von Mises). |

| 6. | Set STRESS CORRECTION to GERBER. |

| 7. | Set STRESSU to MPA (Stress Units). |

| 8. | Set RAINFLOW RTYPE to LOAD. |

| 9. | Set CERTNTY SURVCERT to 0.5. |

Step 7: Defining the Fatigue material properties

The material curve for the fatigue analysis can be defined on the MAT1 card.

| 1. | In the Model browser, click on the Aluminum material. The Entity Editor opens. |

| 2. | In the Entity Editor, set MATFAT, as SN from the list. |

| 3. | Set UTS (ultimate tensile stress) to 600. |

| 4. | For the SN curve set (these values should be obtained from the material’s SN curve). |

SRI1 = 1420.58

B1 = -0.076

NC1 = 5.0e8

SE = 0.1

Step 8: Defining the PFAT card

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 3. | For Card Image, select PFAT. |

Step 9: Defining the FATDEF card

| 1. | In the Model browser, right-click and select Create > Load Collector. |

| 2. | For Name, enter fatdef. |

| 3. | For Card Image, select FATDEF. |

| 4. | Check the box next to PSHELL. |

| 5. | Click  next to the Data field and select shell for PID(1), and pfat for PFATID(1) in the pop-out window. next to the Data field and select shell for PID(1), and pfat for PFATID(1) in the pop-out window. |

Step 10: Defining the fatigue load case

| 1. | In the Model browser, right-click and select Create > Load Step. |

| 2. | For Name, enter Fatigue. |

| 3. | Set the Analysis type to fatigue. |

| 4. | For FATDEF, select fatdef. |

| 5. | For FATPARM, select fatparam. |

| 6. | For FATSEQ, select FATSEQ. |

Step 11: Submitting the OptiStruct analysis and reviewing the results

| 1. | From the Analysis page, go to the OptiStruct panel. |

| 2. | Click save as following the input file: field. A Save As browser window opens. |

| 3. | In File name field, enter the name ctrlarm_hm.fem. |

| 4. | Click Save. The field input file: is set to the location of ctrlarm_hm.fem. |

| 5. | Submit the analysis by clicking on OptiStruct. |

| 6. | When the analysis process completes, click HyperView to launch the results. |

| 7. | In the Results tab, select Subcase 3 (Fatigue) from the subcase field. |

| 8. | Go to the Contour panel in HyperView. |

| 9. | Set Result type to Damage and click Apply to contour the elements. |

Figure 9: Elemental damage results

See Also:

OptiStruct Tutorials