Time Step Scale Factor |

|

|

|

|

|

Time Step Scale Factor |

|

|

|

|

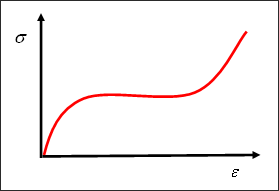

The time step scale factor value is set to 0.9 by default to ensure the stability, taking into account the approximations made in its evaluation. However, in some special cases, a smaller value is required. For example, if the structure becomes stiff suddenly (Fig. 1), due to the material behavior, the critical time step computed for the next step will be smaller than the current one. Therefore, the critical value computed by RADIOSS may be greater than the theoretical critical time step.

Fig. 1: Typical behavior of foam

To avoid this problem, the time step scale factor is reduced. The numerical experience shows that a scale factor around 0.66 may be small enough to avoid time disretization stabilities.

Another typical case is when only one element is used in the model. The shock wave propagation for a mesh with only one element cannot be studied correctly, the time step approximation by RADIOSS may return a higher value, which can be found by theory. In this case, the use of ![]() = 0.1 is recommended.

= 0.1 is recommended.

| 1. | For foams: |

| 2. | Model with one element: |

| 3. | Model with two finite elements: |

| 4. | Model with more than three finite elements: |

| 5. | Never use a scale factor greater than 1.0 |