Transfer Path Analysis on an Automobile |

|

|

|

|

|

Transfer Path Analysis on an Automobile |

|

|

|

|

The function of the transfer path analysis is to determine which body interface dominates the critical NVH response in the interior of the body for a given type of vehicle loading.

The first step is to determine all the transfer functions at all the body interfaces, such as the front and rear cradle mounts, front and rear suspension attachments, powertrain mounts, exhaust hangers and steering system. The major component file in this first run is the fully trimmed body.

One issue that needs to be determined is whether or not the steering column and steering wheel are part of the body model to start with. This would determine to which component these attachments belong. If one of the critical response points is the steering wheel response, then both the steering column and steering wheel must be included with the body model.

The front cradle can also be included in the model and the paths from the front suspension to the front cradle can also be evaluated.

Another requirement is that the body model is in its fully trimmed state and that it contains all bolt-on components that belong to the body, such as the doors, deck lid, hood, seats, instrument panel, etc.

Also the body model will need to include the air cavities, if the transfer path can determine the critical paths causing interior noise problems in the vehicle.

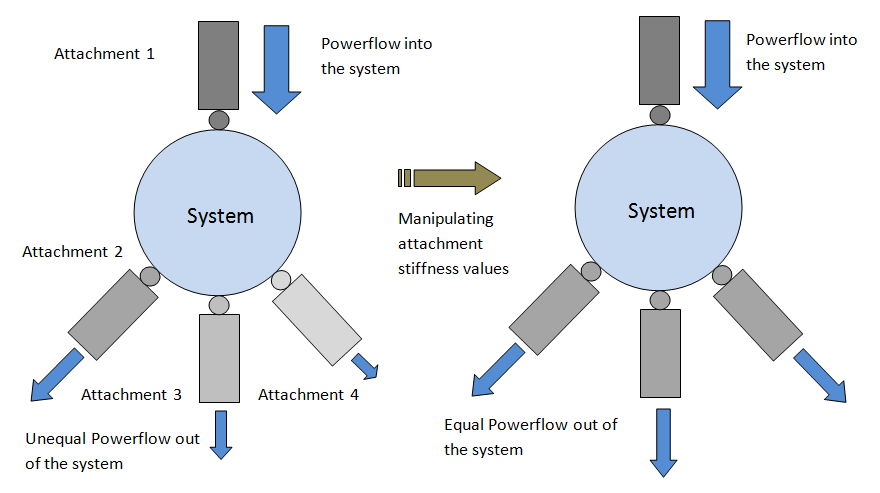

Powerflow can be defined as the flow of energy through a system in a certain amount of time. Powerflow output can be requested by using OptiStruct's POWERFLOW I/O Options Entry. The Powerflow study is useful as it can quantify the amount of energy (magnitude and direction) flowing through various parts of a system. This quantified energy flow can then be correlated with the strain energy levels and other factors, which can help determine the response of a system to applied loading. Consider a system as shown in Figure 1.

Figure 1: Improving Powerflow through various attachments by manipulating their stiffness values.

A real world example, like a body side engine mount bracket can be used to explain Powerflow based on Figure 1. Consider the bracket as the system and that it is connected to the engine mount by the Attachment-1. Additionally, the bracket is also connected to the body at multiple points by the attachments 2, 3 and 4 (called “Legs”). Energy flows into the bracket (system) from the engine mount through Attachment-1 and flows out through the legs (attachments 2, 3 and 4). Energy is also lost through internal damping within the bracket. Strain energy indicates the capacity of each part of the system or attachment to store energy.

Powerflow indicates the rate at which energy is leaving the bracket via structural connections through the legs. This energy flow can be non-uniformly distributed among the legs, due to structural/material differences between them. The amount of energy flowing through each leg is typically proportional to the strain energy level. Additionally, it can also be influenced by other factors, such as impedance (or stiffness) mismatch at the attachment point of each leg. As a result, the stiffness of the legs can be manipulated to redirect the Powerflow from one leg to another, to reduce the response level.

Powerflow can be used in various applications, for example, it can also be used to redirect load paths into the body structure by manipulating body attachment stiffness values.

Below is an example of how to set up the first deck to obtain the required attachment results. The results from this run are used later to determine the transfer load paths for a full vehicle model subjected to a powertrain loading.

OUTPUT, H3D OUTPUT, MASSPROP PARAM, AMLS, YES PARAM, AMLSNCPU, 4 PARAM, AUTOSPC, YES PARAM, CHECKEL, NO TITLE = TRIM BODY MOBILITY ANALYSIS SUBTITLE = WITH CAVITY RESPONSE METHOD(FLUID) = 2 METHOD(STRUCTURE) = 3 FREQUENCY= 1 $ DRIVER'S EAR ACOUSTIC RESPONSE SET 2 = 80000000 ACCELERATION(PUNCH,PHASE) = 1 $ $ UNIT INPUT LOAD AT EACH ATTACHEMENT POINT IN ALL 6 DOF'S $ SUBCASE 2 LABEL = 4003003:+X<>3003:+X<>Frt Susp.:LCA - Frt Bush:LHS:+X DLOAD = 101 DISPLACEMENT (PUNCH,PHASE) = 2 SET 3 = 4003003 VELOCITY (PUNCH,PHASE) = 3 $ SUBCASE 3 LABEL = 4003003:+Y<>3003:+Y<>Frt Susp.:LCA - Frt Bush:LHS:+Y DLOAD = 102 DISPLACEMENT (PUNCH,PHASE) = 2 SET 4 = 4003003 VELOCITY (PUNCH,PHASE) = 4 $ SUBCASE 4 LABEL = 4003003:+Z<>3003:+Z<>Frt Susp.:LCA - Frt Bush:LHS:+Z DLOAD = 103 DISPLACEMENT (PUNCH,PHASE) = 2 SET 5 = 4003003 VELOCITY (PUNCH,PHASE) = 5 $ SUBCASE 5 LABEL = 4003003:+RX<>3003:+RX<>Frt Susp.:LCA - Frt Bush:LHS:+RX DLOAD = 104 DISPLACEMENT (PUNCH,PHASE) = 2 SET 6 = 4003003 VELOCITY (PUNCH,PHASE) = 6 $ SUBCASE 6 LABEL = 4003003:+RY<>3003:+RY<>Frt Susp.:LCA - Frt Bush:LHS:+RY DLOAD = 105 DISPLACEMENT (PUNCH,PHASE) = 2 SET 7 = 4003003 VELOCITY (PUNCH,PHASE) = 7 $ SUBCASE 7 LABEL = 4003003:+RZ<>3003:+RZ<>Frt Susp.:LCA - Frt Bush:LHS:+RZ DLOAD = 106 DISPLACEMENT (PUNCH,PHASE) = 2 SET 8 = 4003003 VELOCITY (PUNCH,PHASE) = 8 $ $ Not all subcases are shown in this example ------------------------------------------------------------------- SUBCASE 273 LABEL = 9005852:+RX<>9011999:+RX<>Frt Susp.:Int. Shaft to Col.::+RX DLOAD = 372 DISPLACEMENT (PUNCH,PHASE) = 2 SET 274 = 9005852 VELOCITY (PUNCH,PHASE) = 274 $ SUBCASE 274 LABEL = 9005852:+RY<>9011999:+RY<>Frt Susp.:Int. Shaft to Col.::+RY DLOAD = 373 DISPLACEMENT (PUNCH,PHASE) = 2 SET 275 = 9005852 VELOCITY (PUNCH,PHASE) = 275 $ SUBCASE 275 LABEL = 9005852:+RZ<>9011999:+RZ<>Frt Susp.:Int. Shaft to Col.::+RZ DLOAD = 374 DISPLACEMENT (PUNCH,PHASE) = 2 SET 276 = 9005852 VELOCITY (PUNCH,PHASE) = 276 $ $ BEGIN BULK $ $ PARAM CARDS FOR ANALYSIS PARAM WTMASS 1. $==01==><==02==><==03==><==04==><==05==><==06==><==07==><==08==><==09==><==10==> $ FREQ1 1 5.0 1.0 195 $==01==><==02==><==03==><==04==><==05==><==06==><==07==><==08==><==09==><==10==> EIGRL 2 600. EIGRL 3 300. ACMODL 4.0 1.0 1.0 1.0 $==01==><==02==><==03==><==04==><==05==><==06==><==07==><==08==><==09==><==10==> $ $ 4003003 +X DLOAD 101 1.0 1.0 401 RLOAD1 401 1001 0 0 400 0 DAREA 1001 4003003 1 1.0 $ 4003003 +Y DLOAD 102 1.0 1.0 402 RLOAD1 402 1002 0 0 400 0 DAREA 1002 4003003 2 1.0 $ 4003003 +Z DLOAD 103 1.0 1.0 403 RLOAD1 403 1003 0 0 400 0 DAREA 1003 4003003 3 1.0 $ 4003003 +RX DLOAD 104 1.0 1.0 404 RLOAD1 404 1004 0 0 400 0 DAREA 1004 4003003 4 1.0 $ 4003003 +RY DLOAD 105 1.0 1.0 405 RLOAD1 405 1005 0 0 400 0 DAREA 1005 4003003 5 1.0 $ 4003003 +RZ DLOAD 106 1.0 1.0 406 RLOAD1 406 1006 0 0 400 0 DAREA 1006 4003003 6 1.0 $ $ Not all load cards are shown in this example ---------------------------------------------------------------------------- $ $==01==><==02==><==03==><==04==><==05==><==06==><==07==><==08==><==09==><==10==> TABLED1 400 +400A +400A 20.0 1.0 400.0 1.0 ENDT $ INCLUDE '/ANALYSIS/TRIM_BODY_CONNECTIONS.dat' INCLUDE '/MODELS/CAVITY/CAVITY.dat' INCLUDE '/ANALYSIS/TRIM_BODY_FILES.dat' INCLUDE '/MODELS/FRONT_CRADLE/FRONT_CRADLE.dat' INCLUDE '/MODELS/STEERING/STEERING_COLUMN.dat' INCLUDE '/MODELS/STEERING/STEERING_WHEEL.dat' ENDDATA |

|

The label card: LABEL = 4003003:+X<>3003:+X<>Frt Susp.:LCA - Frt Bush:LHS:+X

The first parameter defines the input attachment point and its loading direction. The second parameter defines a shortened version of this input attachment point. The third parameter defines the attachment by its name and also includes the loading direction. The creation of the subcases and this labeling information will be automated in a future release of NVH Director.

The major output from this analysis is the displacement and velocity output in the .pch file, which can be around 40 MB in size.

The second run is a full vehicle model analysis with a particular critical loading on one of the non-body components. Below is an example of a P/T type of analysis. A torque loading is applied to the crankshaft and the acoustic response at the driver’s ear is captured.

OUTPUT, H3D OUTPUT, MASSPROP PARAM, AMLS, YES PARAM, AMLSNCPU, 4 PARAM, AUTOSPC, YES PARAM, CHECKEL, NO $MODEL,100 $ TITLE = P/T FULL VEHICLE ANALYSIS SUBTITLE = BASELINE COMPONENTS MPC = 406 SPC = 1 $ Acoustic response output set SET 1 = 80000000, 80000002, 80000004, 80000006 $ Structural response output set SET 2 = 1006001,9106012 $ Body attachment forces SET 3 = 1002001,1002001,1002002,1002003,1002004,1003015,1003016, 1003521,1004503,1004507,1004515,1004523,1005003,1005004, 1005011,1005012,1005013,1005014,1005015,1005016,1005017, 1005018,2005807,2005809,2005810,4003003,4003004,4003005, 4003006,4003007,4003008,4003501,4003511,4003541,4005811, 4005812,9005852 INCLUDE 'display_set.dat' $ This file contains set 200 that has the full vehicle plotel grid points identified. $ SUBCASE 1 $ MODAL DEFLECTION SHAPE LABEL = P over T Modal METHOD(FLUID) = 2 METHOD(STRUCTURE) = 3 DISPLACEMENT(H3D)= 200 $ SUBCASE 2 $ FREQUENCY RESPONSE ANALYSIS LABEL = P over T Baseline METHOD(FLUID) = 2 METHOD(STRUCTURE) = 3 DLOAD = 110 FREQUENCY= 1 GPFORCE (PUNCH,PHASE) = 3 DISPLACEMENT(PUNCH,PHASE)= 1 DISPLACEMENT(H3D,PHASE)= 1 ACCELERATION (PUNCH,PHASE) = 2 ACCELERATION (H3D,PHASE) = 2 $ SUBCASE 3 $ OPERATING DEFLECTION MODE SHAPE LABEL = P over T Post METHOD(FLUID) = 2 METHOD(STRUCTURE) = 3 $ Critical Frequencies specified in set 300 SET 300 = 54.0,64.0,80.0,92.0,104.0,114.0,146.0 OFREQ = 300 DLOAD = 110 FREQUENCY= 1 DISPLACEMENT(H3D)= 200 $ BEGIN BULK $ $ PARAM CARDS FOR ANALYSIS PARAM WTMASS 1. $ $==01==><==02==><==03==><==04==><==05==><==06==><==07==><==08==><==09==><==10==> FREQ1 1 5.0 1.0 195 EIGRL 2 600. EIGRL 3 300. ACMODL 4.0 1.0 1.0 1.0 $ INCLUDE '/ANALYSIS/P_OVER_T/PT_LOADS.dat' $ INCLUDE '/ANALYSIS/P_OVER_T/PT_CONNECTIONS_FULL.dat' $ INCLUDE '/ANALYSIS/FULL_VEHICLE_FILES_W_CAVITY.dat' ENDDATA |

This run also puts out a large .pch file that includes the response and the body attachment forces.

Once these two runs are completed, a transfer patch analysis can be performed in HyperView.

To perform a transfer path analysis on this model, open up HyperView.

| 1. | From the File menu, select Load > Preference File. |

| 2. | From the Preference dialog, select NVH Utilities and click Load. |

| 3. | From the NVH menu, select Transfer Path Analysis. |

| 4. | Click on the file browser icon to select a Transfer Function file. |

This is the PCH from the first run.

| 5. | Click on the file browser icon to select a Force file. |

| 6. | Select Load. |