Deformable Strut |

|

|

|

|

|

Deformable Strut |

|

|

|

|

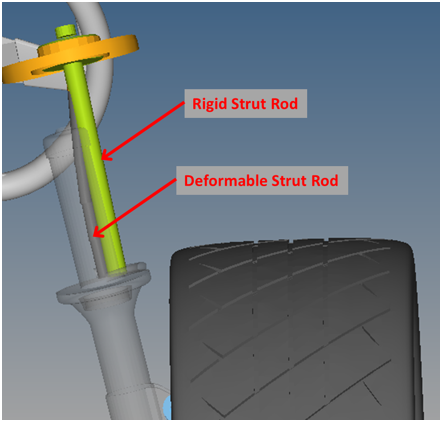

In the Deformable Strut system, the strut rod is modeled by beams and the strut tube to strut rod joint is modeled by a point to deformable curve constraint. This allows the strut to bend under load and captures the camber change due to lateral force common to strut suspensions.

Deformable Strut System

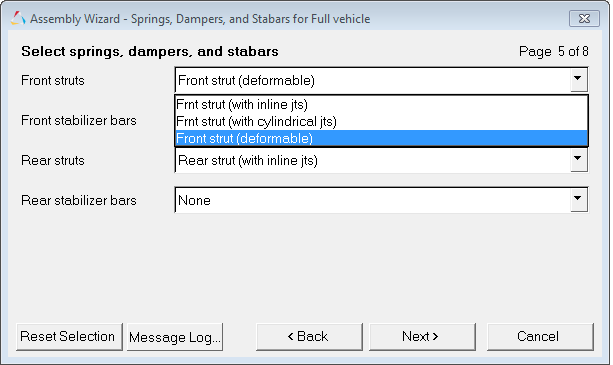

The deformable strut system is available in the MDLLIB’s MacPherson Strut front and rear suspensions and the Quadlink rear suspension. To use deformable struts in a model, simply select Deformable strut from the Front-struts or Rear-struts option menus in the Assembly Wizard as shown below:

Users with existing suspension or full vehicle models that wish to use the deformable strut can import the system definition sysdef_deformable_strut from:

$ALTAIR_HOME/hw/mdl/mdllib/Libs/Models/Frnt_strut/deformable_strut.mdl

You can use MotionView’s system Import feature by following the steps below:

| 1. | Select the model, or system within your model, to which you want to add the deformable strut. |

| 2. | Select the Import/Export tab in the panel area of MotionView. |

| 3. | Pick the Import radio button. |

| 4. | Select the file: $ALTAIR_HOME/hw/mdl/mdllib/Libs/Models/Frnt_strut/deformable_strut.mdl. |

| 5. | Press the Import button. |

The deformable strut includes options for attaching to other systems and an option to set the system compliance.

The Deformable Strut system takes as input bodies and points to which the upper and lower ends of the strut attach to, and points defining the upper and lower strut and spring locations.

|

The Deformable Strut system provides an option called Compliant. Setting this option to No switches the upper strut joints to non-compliant universal joints. The default state is Yes (On).

Deformable Strut System - Options |

The Deformable Strut system includes parameters for setting the strut rod and strut tube lengths. All of the point locations are parametric to these parameters. The length values are set using the Strut rod length and Strut tube length fields found in the dataset within in the deformable strut system. Additionally, the diameter of the strut rod can be set using the field labeled Strut Rod Diameter. The Strut length field is calculated automatically through an expression which uses the strut end points.

|

The points defined in the deformable strut exist primarily to:

All of the points are parametric to the upper and lower strut attachment points, the strut total length, the strut rod length, and the strut tube length. Each of these points are described in detail below.

Principal Points - Deformable Strut Strut Rod LowerThe Strut Rod Lower is a PointPair with the left side being the symmetric side. It is the lowest end of a strut rod in a deformable strut and is located within the strut tube. The expression for calculating the coordinates for this point are shown in the table below:

The variables used in the expression above are described below:

As seen from the above table, the coordinates are determined by the upper and lower strut locations, the total strut length, and the strut rod length. Strut Tube UpperThe Strut Tube Upper is a PointPair with the left side being the symmetric side. It is the top end of the strut tube in a deformable strut. The expression for calculating the coordinates for this point are shown in table below:

The variables used in the expression above are described below:

Flexible Rod - LeftThe Flexible Rod points are a set of five points located equidistant from each other between the strut rod upper and strut rod lower points. The points are used to connect the individual beams in the polybeam –left and also define the control points for the deformable curve - left. Their label is suffixed with a number ranging from 0 to 4. For example, the point “Left Flexible Rod0” is the first point, “Left Flexible Rod1” the second point, and so on with the “Left Flexible Rod4” being the last. Since the polybeam cannot be modeled as a pair, the points are defined individually for each side (instead of being pairs). The expressions used to calculate the coordinate values for the left side are shown below:

The variables used in the expression above are described below:

Flexible Rod - RightThe flexible rod points on the right are defined similar to the flexible rod points on the left. They use the points on the right side to calculate their locations. The expressions used to calculate the coordinate values for the right side are shown below:

The variables used in the expression above are described below:

Strut Tube CGThe Strut Tube CG point is a PointPair used to locate the CG location for the Strut tube body and is a parametric value. The values are symmetric with the values on the LEFT being used on both sides. The coordinates use the following expressions:

The variables used in the expression above are described below:

|

|---|

The Deformable Strut system consists of two polybeams, one for each side, that simulate the behavior of the strut rod. The polybeam is defined with a circular section whose diameter is parametric and is set through the dataset option labeled “Strut rod diameter”.

PolyBeam - Deformable Strut The table below describes the connections for both polybeams:

The table below describes the properties for the polybeams:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Deformable Strut system consists of two deformable curves – one for each side. The curve determines the path followed by the strut tube upper point when connected through an advanced joint. The control points for the curve are determined by markers.

Deformable Curve - Deformable Strut The table below describes the deformable curves:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Deformable Strut system consists of fifteen markers. Fourteen of these are split equally on each side and are used to define the deformable curve. The remaining marker is a pair and is used to orient the coil spring. The table below describes the connections for markers:

|

The Deformable Strut system consists of two advanced joints to connect each side of the strut tube to the deformable curve. The table below describes the advanced joint connections:

|

The Deformable Strut system consists of a two bodies as shown in the figure below:

Bodies - Deformable Strut The Strut Tube (Lower Strut) simulates the tube in a deformable strut that generally stores fluid. When internal bumpstops are included in the suspension, they are attached with the help of the BodyPair - Attachment for internal bumpstops. The default mass and inertia properties for the bodies are shown below:

|

The Deformable Strut system primarily consists of joints connecting the strut tube to the strut rod and the strut tube to the knuckle.

Joints - Deformable Strut The table below describes the joints with the bodies and points they are resolved to:

Note - The cylindrical joints connecting the polybeam strut rod and strut tube, the universal joints connecting the vehicle to the strut rod and the fixed joints connecting the strut rod to the bumpstop attachments are not modeled as pairs. |

The bushings are located at the upper ends of the deformable strut.

Bushings - Deformable Strut The table below describes them:

The stiffness and damping properties for both bushings are shown in the table below:

|

The Deformable Strut system is modeled with a two spring-damper force elements. One acts as a pure damper while the other acts as a coil spring with no damping.

Spring Damper - Deformable Strut The table below describes their connections and properties.

|

The Deformable Strut system consists of four outputs for the strut shock displacement and strut coil spring displacement for each side. The strut shock displacement is measured by the relative displacement of the piston rod joint. The image below shows the output plotted for the left shock strut in the vertical direction:

The coil spring displacement is measured as the relative displacement of the spring damper. The image below shows the output plotted for the left coil spring displacement in the vertical direction:

|

The deformable strut dataset is used to specify the length of the strut rod, strut tube, and the strut rod diameter. The total length of the strut is parametric and is calculated by the coordinates of the upper and lower strut attachment locations.

The dataset “Strut rod/tube dimensions” is used to set the lengths for the following:

Strut lengthThe “Strut length” sets the overall length of the strut and is a parametric expression and is calculated from the location co-ordinates for the upper and lower strut attachments.

Therefore the above formula shows up in the dataset as:

The variables used in the expression above are described below:

The expression can be overridden with a user entered value which affects the location of the following entities:

Strut rod lengthThe “Strut rod length” as the name suggests sets the length of the strut rod. The value is user-defined . Entities that pick values from the “Strut rod length” are:

Strut tube lengthThe “Strut tube length” as the name suggests sets the length of the strut tube. The value is user-defined. Entities that use the value from the “Strut tube length” are:

Strut rod diameterThe “Strut rod diameter” as the name suggests sets the diameter of the strut rod. The value is user-defined. Entities that use the value from the “Strut rod diameter” are:

|

If the jounce or rebound bumper is built as internal, it means the bumper is inside the deformable strut. These bumpers have a lot of parametric equations which define the location and length of the bumper. See the Jounce bumper description for further information. |

The Deformable strut system can be used in either a half vehicle or a full vehicle models for the Macpherson and quadlink suspensions. Usage Notes

|