Rear Trailing Arm |

|

|

|

|

|

Rear Trailing Arm |

|

|

|

|

A Rear Trailing Arm suspension is included in the Vehicle Library. The Trailing Arm suspension is an independent rear suspension system in which the wheel is attached to the trailing end of an arm that pivots on a bushing (this allows the wheel to move up and down). The suspension design requires a trailing arm that is flexible in order to work. A flexbody is normally used to simulate the trailing arm body.

Rear Trailing Arm Suspension

The Rear Trailing Arm suspension offers a standard set of attachments, options, and properties that you can set by selecting the suspension system in the Project Browser to display the System/Assembly panel.

Attachments determine how the suspension system attaches to the remainder of the vehicle system. The Rear Trailing Arm includes attachments for the trailing arm, the upper link, and the lower link:

| - | The trailing arm, the upper link, and the lower links attach to the sub-frame by default. When a sub-frame is not present in the model, the Assembly Wizard attaches the trailing arm and both links to the vehicle body. If the vehicle body is not present, for example in a half vehicle model, then the Assembly Wizard will attach them to ground. You can set the attachment for the trailing arm and the upper and lower links using the Attachment Wizard from the Model menu, or by selecting the Rear Trailing Arm suspension system in the Project Browser and revising the attachments within the Attachments tab on the System/Assembly panel. |

The Rear Trailing Arm suspension like all Vehicle Library suspension systems includes a Compliant option. When the Rear Trailing Arm suspension’s Compliant option is set to No, the trailing arm bushings are replaced with ball joints, the stiffness panel gets activated, and the rotational axis directed along the line from the left bushing to the right bushing.

The Rear Trailing Arm suspension also includes a Spindle compliance option. When the Spindle compliance option is set to Yes, the wheel body connects to the wheel hub via a universal joint and bushing. The wheel hub bushing’s Kx and Ky rates determine the amount of spindle compliance introduced.

The Rear Trailing Arm suspension includes a static alignment dataset and form holding toe and camber variables that determine the orientation of the wheel relative to the knuckle and body in the Global coordinate system. The toe and camber variable values control the location of the spindle align point relative to the wheel center point through parametric expressions. You can view these expressions by selecting the spindle align point and examining its X, Y, and Z locations.

To set the values for toe and camber, select either the static alignment dataset or form and alter the values of the toe and camber variables. Note that the left and right wheels’ toe and camber values must be symmetric. You cannot set the toe and camber angles independently for the two wheels.

Select options using the Assembly Wizard to include stabilizer bar, spring, shock-absorber, jounce bumper, or rebound bumper subsystems in the model.

When you finish creating your model using the Assembly Wizard, the subsystems you have chosen show in the Project Browser as children of the Rear Trailing Arm suspension. The table below shows the optional subsystems available with the Rear Trailing Arm suspension:

Subsystem |

Options |

Stabilizer Bar |

None |

Stabilizer Bar with Links |

Two (2) Piece Bar with Links |

Spring |

None |

Coil Springs |

---- |

Shock Absorber |

None |

Two (2) Inline Joints |

One (1) Cylindrical Joint |

Jounce Bumper |

None |

Internal Jounce Bumper |

External Jounce Bumper |

Rebound Bumper |

None |

Internal Rebound Bumper |

External Rebound Bumper |

| • | Internal jounce and rebound bumpers act between the shock tube and the shock rod. |

| • | External jounce and rebound bumpers act between the lower lateral link and the Vehicle Body. |

| • | Suspensions created without a spring or a shock absorber subsystem will not function in a full vehicle analysis. |

| • | You can alter how optional subsystems attach to the suspension by selecting the subsystem in the Project Browser and altering the subsystem’s attachments. |

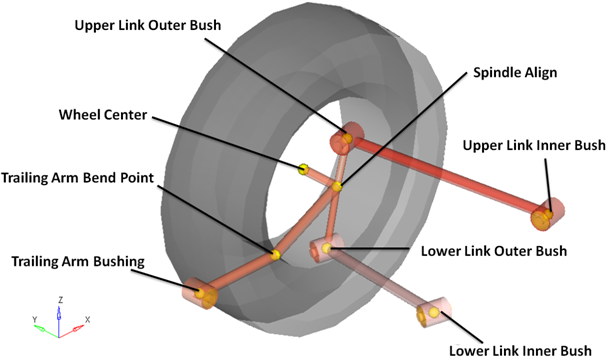

Points locate the joints and bushings in the suspension. The image below shows the principal points for the Rear Trailing Arm suspension:

Right Side Principal Points – Rear Trailing Arm Suspension

| Note | The image above omits the left side of the suspension, points locating body centers of mass, and points that locate the optional subsystems (springs, dampers, bump stops and stabilizer bar) for clarity. |

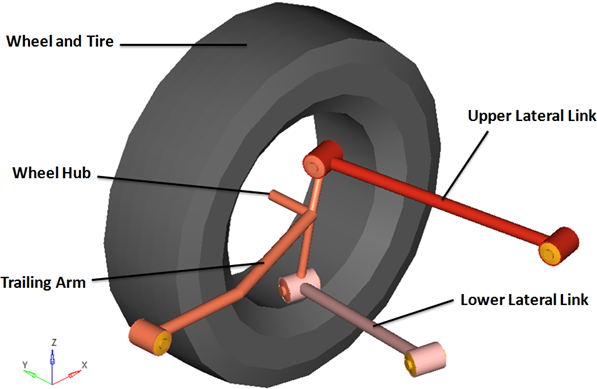

The Rear Trailing Arm suspension is comprised of the bodies shown in the image below:

Right Side Bodies – Rear Trailing Arm Suspension

| Note | The wheel hub body has no associated graphics and therefore is not visible in the image above. |

Optional subsystems may add bodies to the suspension, for example the shock absorber adds two bodies: a shock rod and shock tube. Any bodies added by optional subsystems have been omitted from the image above for clarity.

The table below describes the bodies, bushings, and joints for the Rear Trailing Arm suspension:

| Note | The table omits the left side joints for clarity. |

Label |

Type |

Body 1 |

Body 2 |

Point |

|---|---|---|---|---|

Wheel Spindle Joint |

Revolute |

Wheel Hub |

Trailing arm |

Wheel Center |

Wheel Hub Fix Joint |

Fixed |

Wheel |

Wheel Hub |

Wheel Center |

Trailing arm Bush |

Ball |

Trailing arm |

Vehicle Body |

Trailing arm Bush |

Lower Link Outer Bush |

Ball |

Lower Lateral Link |

Trailing arm |

Lower Link Outer Bush |

Upper Link Outer Bush |

Ball |

Upper Lateral Link |

Trailing arm |

Upper Link Outer Bush |

Lower Link Inner Bush |

Universal |

Lower Lateral Link |

Ground Body |

Lower Link Inner Bush |

Upper Link Inner Bush |

Universal |

Upper Lateral Link |

Ground Body |

Upper Link Inner Bush |

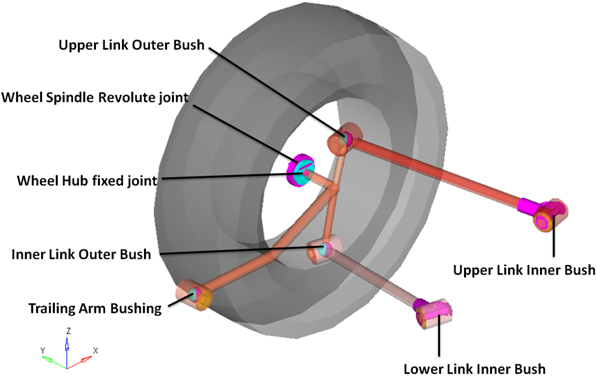

The figure below shows the location of the joints and bushings in the suspension:

Right Side Joints and Bushings: Rear Trailing Arm Suspension

The Rear Trailing Arm suspension system can be used in either a half car or a full vehicle analysis. The default geometry and mass is that of a passenger car or light truck, however the model and data can be revised to reflect any size vehicle, from a large truck to a scale model car.

| • | The wheel body represents the mass and inertia of the tire and the rim. |

| • | The wheel hub body represents the mass and inertia of other rotating bodies such as a brake rotor, but not the half-shafts if the suspension is driven. The wheel hub and brake rotor have no associated graphics. |

| • | The wheel and wheel hub parts use the Wheel CG location as the center of gravity. |

| • | Each body’s Center of Gravity (CG) is estimated from the body’s geometry. The formulas are coded into the point panel and can be seen via the graphical user interface. If more accurate CG locations are available, they should be used. |

| • | A wide variety of combinations of suspensions and subsystems can be built using the Assembly Wizard. You are encouraged to build systems and understand the resulting model using the graphical user interface. |

| • | When building a new suspension model, build the model with all of the optional systems (stabilizer bar, etc) included in the model. Immediately turn off the systems via the Project Browser and run an analysis on the base suspension to ensure it solves properly. As data becomes available for the optional systems, activate those systems and populate them with data. |

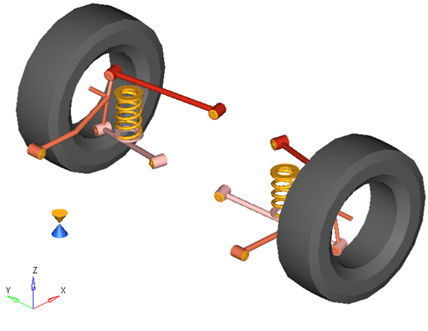

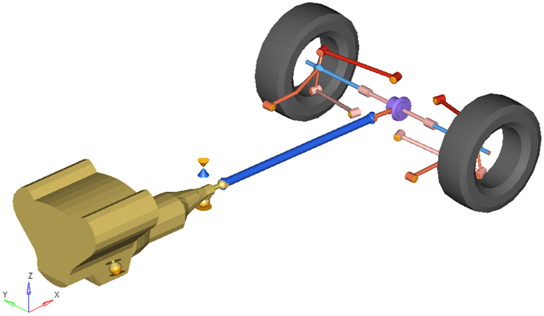

Rear-Half-Vehicle Model Employing a Trailing Arm Suspension

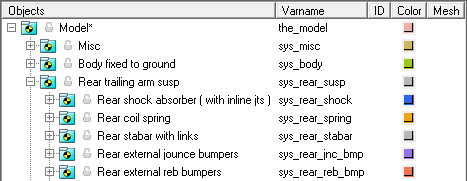

The image below shows the MotionView Project Browser view of the systems in a fully populated rear suspension model. The Rear trailing arm susp system has five “child” systems.

Browser view of a Rear-Half-Vehicle Model Systems and Subsystems Employing a Trailing Arm Suspension