Step 1: Load the Engineering Solutions RADIOSS user profile

| 1. | From the Start menu, select Engineering Solutions > Crash (HyperMesh) or click  on the Standard toolbar. on the Standard toolbar. |

| 2. | Select Crash > RADIOSS. |

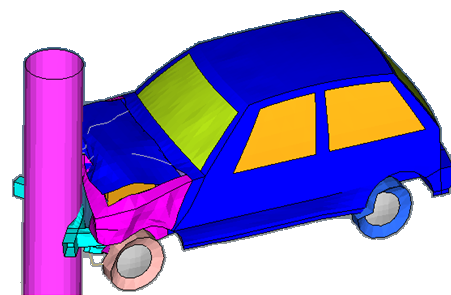

Step 2: Load the model file

| 1. | Click the Open Model icon  on the Standard toolbar. on the Standard toolbar. |

| 2. | In the Open Model dialog, navigate to the fullcar.hm file. |

| 3. | Click Open. The model loads into the graphics area. |

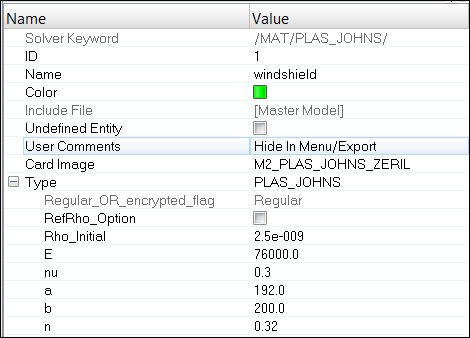

Step 3: Create and assign the material for the windshield components

| 1. | In the Model browser, right-click and select Create > Material. The Entity Editor is displayed below the Model browser. |

| 2. | For Name, enter windshield. |

| 3. | Set Card Image as M2_PLAS_JOHNS_ZERIL and click Yes to confirm. |

| 4. | Input the values, as shown below: |

| 5. | In the Model browser, select components COMP-PSHELL_3 and COMP-PSHELL_16. |

| 6. | Click Mat_Id in the EE, select the material windshield and click OK to update the selected components with the created material. |

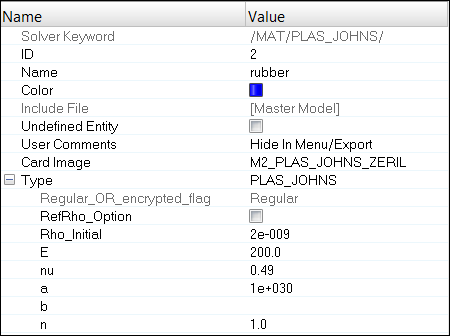

Step 4: Create and assign the material for the rubber components

| 1. | In the Model browser, right-click and select Create > Material. The Entity Editor is displayed. |

| 2. | For Name, enter rubber. |

| 3. | Set Card Image to M2_PLAS_JOHNS_ZERIL and click Yes to confirm. |

| 4. | Input the values, as shown below: |

| 5. | In the Model browser, select components COMP-PSHELL_20 through COMP-PSHELL_23. |

| 6. | For Mat_Id, select the material rubber and click OK to update the selected components with the created material. |

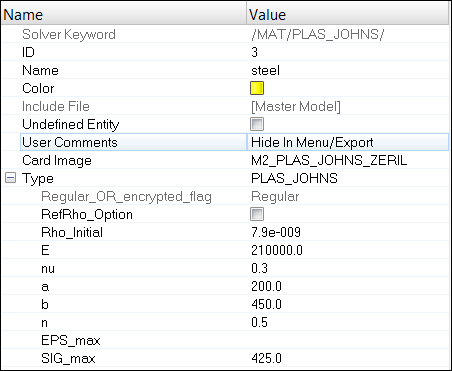

Step 5: Create Steel material and assign to all other parts

| 1. | In the Model browser, right-click and select Create > Material. The Entity Editor is displayed. |

| 3. | Set Card Image to M2_PLAS_JOHNS_ZERIL. |

| 4. | Input the values, as shown below: |

| 5. | In the Model browser select all components labeled with COMP-PSHELL and COMP-PROD, except COMP-PSHELL_3, COMP-PSHELL_16 and COMP-PSHELL_20 to COMP-PSHELL_23. |

| 6. | For Mat_Id, select the material steel and click OK to assign the material to the selected components. |

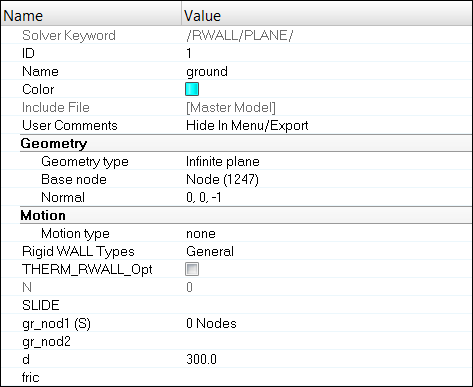

Step 6: Create a Rigid Wall

| 1. | In the Model browser, right-click and select Create > Rigid Wall. The Entity Editor is displayed. |

| 2. | For Name, enter ground. |

| 3. | Set Geometry type as Infinite plane. |

| 4. | Click Base node and select 'any node' from the model. |

| 5. | Define the normal vector Z = -1. |

| 7. | Go to the Setup > Rigid Walls panel. |

| 9. | Click name and select Ground from the list. |

| 10. | Click the edit tab besides base node and change values of the coordinates as indicated below. |

X = -2300, Y = 1200, and Z = -1.

| 11. | Click update > return. |

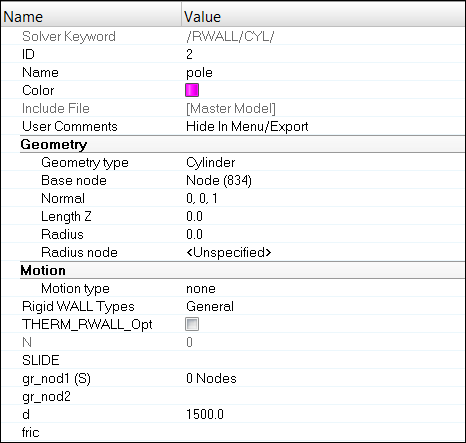

Step 7: Create a Cylindrical Rigid Wall to represent Pole

| 1. | In the Model browser, right-click and select Create > Rigid Wall. The Entity Editor will display. |

| 3. | Set the Geometry type as Cylinder. |

| 4. | Click Base node and select ‘any node’ from the model. |

| 5. | Define the normal vector Z= 1. |

| 6. | For Radius node, do not select anything. Leave it as <Unspecified>. |

| 8. | Go to Setup > Rigid Walls panel. |

| 10. | Click name and select Pole from the list. |

| 11. | Click the edit tab besides base node and change values of the coordinates as indicated below. |

X = -320, Y = 1250, and Z = 0.

| 13. | Click update > return. |

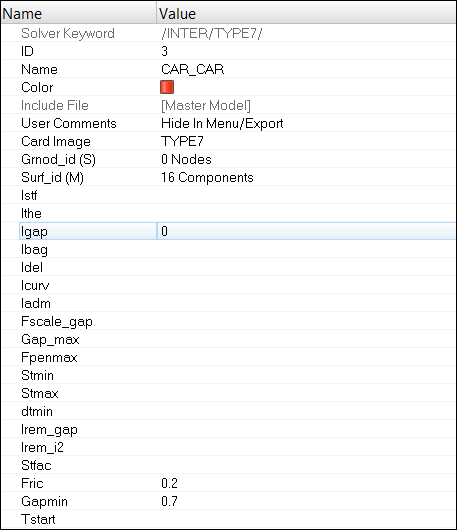

Step 8: Defining Contact using TYPE 7 interface (Self Contact)

| 1. | Hide all the 1D (TRUSSES) and 3D (SOLID) parts in the model by going to the Solver browser PROP > SHELL, Isolate only. Return to the Model browser. |

| 2. | From the Model browser, right-click and select Create > Contact. The Entity Editor will display. |

| 3. | For Name, enter CAR_CAR. |

| 4. | Set Card Image to TYPE7 and click Yes to confirm. |

| 5. | Set the option to Components for Surf_id (M) (master entity), and select displayed components and click OK. |

| 6. | Input other parameters as shown below. |

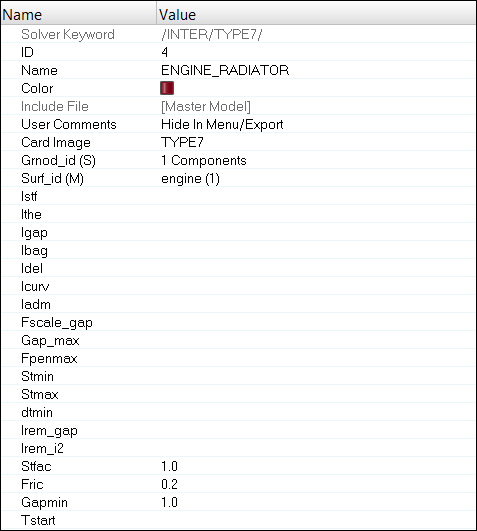

Step 9: Defining Contact using TYPE 7 interface between Engine and Radiator

| 1. | In the Solver browser, right-click and select Create > SURF_EXT > PART. |

| 2. | For Name, enter engine. |

| 3. | Click on Components and select COMP-PSOLID_24. |

| 4. | In the Model browser, right-click and select Create > Contact. |

| 5. | For Name, enter ENGINE_RADIATOR and set the Card Image as TYPE7 and click Yes to confirm. |

| 6. | For Grnod_id (S) (slave entity), set the selector switch to Components and click Components, select COMP-PSOLID_26. |

| 7. | For Surf_id (M) (master entity), set the selector switch to Set and click Set, select engine. |

| 8. | Input the values, as shown below: |

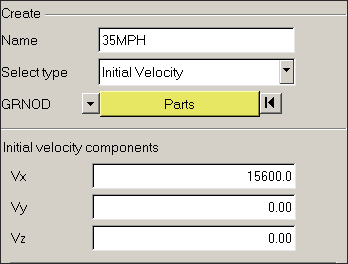

Step 10: Defining initial velocity

| 1. | From the Utility menu, click the BC's Manager or click the BCs Manager icon  in the Crash toolbar. in the Crash toolbar. |

| 2. | For Name, enter 35MPH, set the Select type field to Initial Velocity and set GRNOD to Parts. |

| 3. | Click comps and select all of the parts in the model. |

| 5. | Click Create to create the boundary condition and boundary condition appears in the table. |

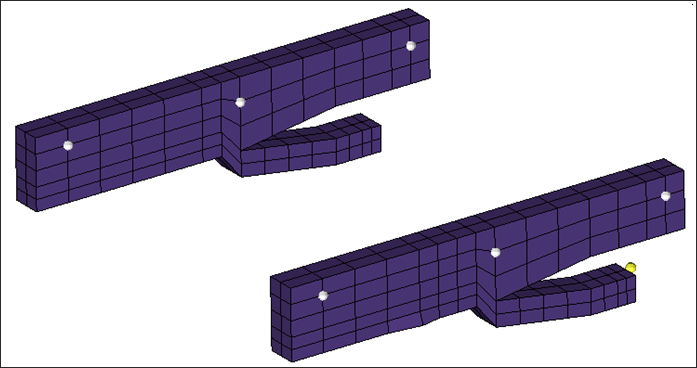

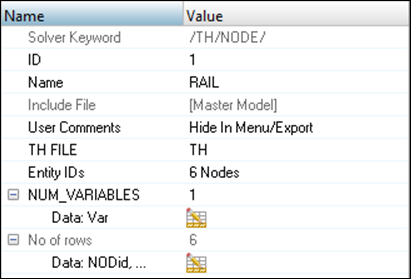

Step 11: Create Time History Nodes

| 1. | In the Model browser, isolate COMP-PSHELL_19. |

| 2. | Click Tools > Create Solver Cards > TH > NODE. |

| 3. | For Name, enter RAIL and select nodes on the Rail, as shown below. |

| 4. | For NUM_VARIABLES, select 1 and for Data: Var, enter the following: |

Step 12: Create output requests and control cards

| 1. | Launch the Solver browser by selecting View > Solver Browser. |

| 2. | Right-click in the Solver browser general area to create the cards shown below with the given values for each parameter: |

Keyword Type

|

Keyword

|

Parameter

|

Parameter Value

|

CONTROL CARDS

|

TITLE

|

Status

|

[Checked]

|

CONTROL CARDS

|

TITLE

|

TITLE

|

Car_Analysis

|

ENGINE KEYWORDS

|

RUN

|

Status

|

[Checked]

|

ENGINE KEYWORDS

|

RUN

|

Run Number

|

1

|

ENGINE KEYWORDS

|

RUN

|

Tstop

|

0.0601

|

ENGINE KEYWORDS

|

PRINT

|

Status

|

[Checked]

|

ENGINE KEYWORDS

|

PRINT

|

N_Print

|

-1000

|

ENGINE KEYWORDS

|

TFILE

|

Status

|

[Checked]

|

ENGINE KEYWORDS

|

TFILE

|

Time Frequency

|

9e-5

|

ENGINE KEYWORDS

|

ANIM/ELEM

|

Status

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/ELEM

|

EPSP

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/ELEM

|

VONM

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/ELEM

|

HOURG

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/VECT

|

Status

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/VECT

|

VEL

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/VECT

|

CONT

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/VECT

|

FOPT

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/DT

|

Status

|

[Checked]

|

ENGINE KEYWORDS

|

ANIM/DT

|

TStart

|

0

|

ENGINE KEYWORDS

|

ANIM/DT

|

Tfreq

|

0.003

|

Step 13: Export the model

| 1. | Click File > Export or click the Export icon  . . |

| 2. | Enter a filename in the destination directory where you want to run. |

| 3. | Enter the name FULLCAR and click Save. |

| 4. | Click the downward-pointing arrows next to Export options to expand the panel. |

| 5. | Click Merge starter and engine file to export the engine file with the model in one file. |

| 6. | Click Export to export both model and engine file. |

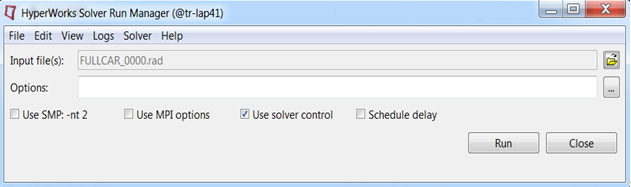

Step 14: Run the solver using RADIOSS Manager

| 1. | Go to Start > Programs > Altair HyperWorks <version> RADIOSS. |

| 2. | For Input file, browse to the exercise folder and select the file FULLCAR_0000.rad. |

Step 15 (Optional): View the Results in HyperView

The exercise is complete. Save your work to a HyperMesh file.

|