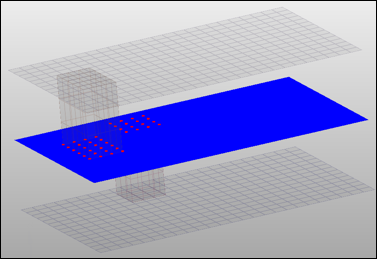

dyna rigid (crbody)

The dyna rigid (crbody) exists in exactly the same configuration with the following additional names:

This is in order to keep the realization names from HyperCrash.

|

CFG dyna 5 rigid (crbody)

*filter spot

*head

*body 0

rigid 2 1

*post prop_rigid_crbody.tcl

|

|

Description: Creates a RgdBody element for the body.

This realization also uses the prop_rigid_crbody.tcl property script.

This script updates mesh-dependent rigid welds > 2T into rigidlinks sharing a node. This is a requirement for the LS-DYNA *CONSTRAINED_NODAL_RIGID_BODY definition.

|

|

dyna ConNode (spider)

The dyna ConNode (spider) exists in exactly the same configuration with the following additional names:

This is in order to keep the realization names from HyperCrash.

|

CFG dyna 56 ConNode (spider)

*filter bolt

*style bolt 2

*head

*body 0

rigidlink 1 1

|

|

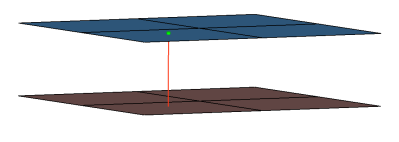

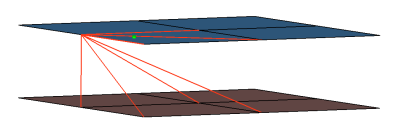

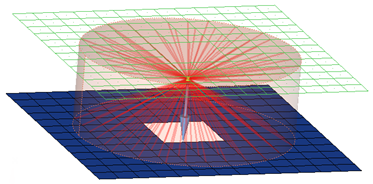

Description: Creates a ConNode rigidlink element for the body. It connects to the nearest node to the connector position and then projects to the nearest nodes on the adjoining elements of the connected components.

|

dyna RgdBody (spider)

CFG dyna 57 RgdBody (spider)

*filter bolt

*style bolt 2

*head

*body 0

rigidlink 2 1

|

|

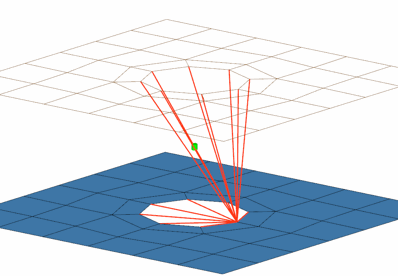

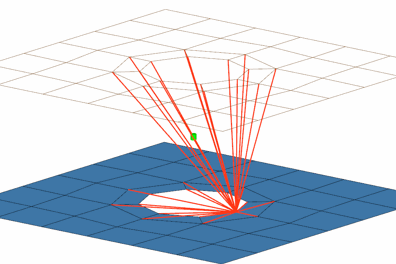

Description: Creates a RgdBody rigidlink element for the body. It connects to the nearest node to the connector position and then projects to the nearest nodes on the adjoining elements of the connected components.

If holes are detected the nodes on the edges are connected.

|

dyna RgdBody (spider+washer)

CFG dyna 58 RgdBody (spider+washer)

*filter bolt

*style bolt 21

*head

*body 0

rigidlink 2 1

|

|

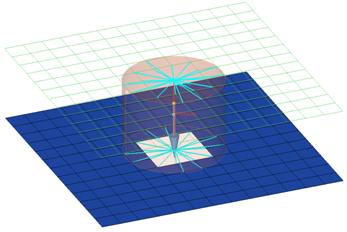

Description: Creates a RgdBody rigidlink element for the body. It connects to the nearest node to the connector position and then projects to the nearest nodes on the adjoining elements of the connected components.

If holes are detected the nodes on the edges and the washer nodes are connected.

|

dyna acm (shell gap + coating)

CFG dyna 72 acm (shell gap + coating)

*filter spot

*style acm 4

*body 0

hex8 1 1

*post prop_acm_coating.tcl

|

|

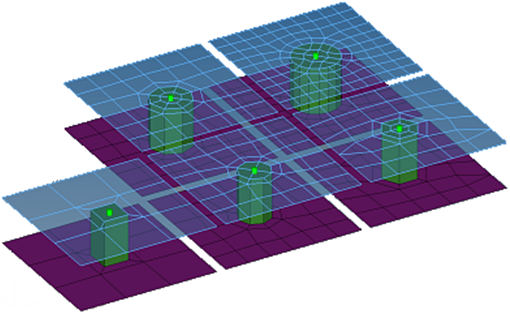

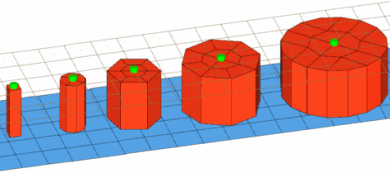

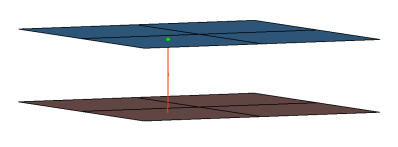

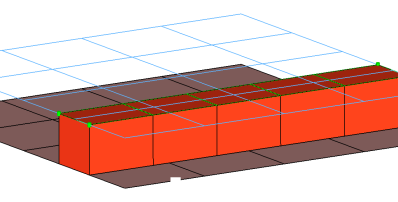

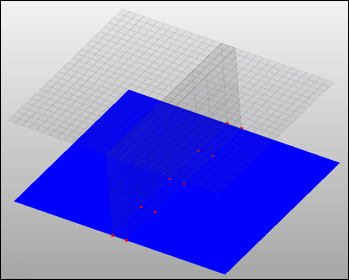

Description: This realization creates one hexa cluster per connector, and realizes a node to node connection to the linked shell meshes by adjusting it (shell coating). Different patterns are available. This is driven by the number of hexas. The appearance can be influenced via the diameter and the washer layer activation.

This realization uses the prop_acm_coating.tcl property script.

The script performs the following tasks:

| 1. | Organizes the HEXA elements into a set with the name CE_HEXSW_# (# starts with 1 and increments as 1, 2, 3, and so on for every new connector). |

|

|

dyna mat100

The dyna mat100 exists in exactly the same configuration with the following additional names:

| • | HC glue structural adhesive |

This is in order to keep the realization names from HyperCrash.

|

CFG dyna 100 mat100

*filter spot

*head

*body 0

bar2 1 1

*post prop_dyna_matnum.tcl

|

|

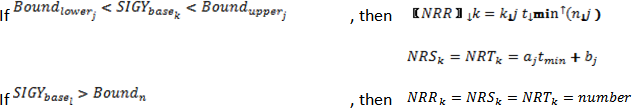

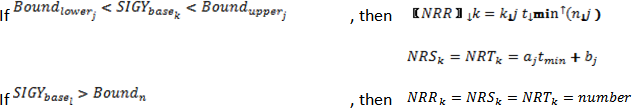

Description: Creates a BEAM element for the body and plot elements for the head, the plot elements are created for visualization purposes and find operations.

This realization also uses the prop_dyna_matnum.tcl property script.

This script is used while creation of mat100/mat100 (hexa)/mat196 custom config welds in the Spot panel. It does the following tasks.

| • | Organizes the realized weld elements to the respective components based upon the link they are connected to and based upon the realization used. |

If a weld is created as mat100 between comp_1(id1) and comp_2(id2), it will create a component collector with the name C_^_<id1_id2>_BEAM_100 and organize all of the welds created as links between these two components into this collector.

If a weld is created as mat100 between the three components comp_1(id1), comp_2(id2) and comp_3(id3), it will create two component collectors, C_^_1W_<id1_id2>_BEAM_100 and C_^_1W_<id2_id3>_BEAM_100. The suffix is based on the realization type:

Mat100: _BEAM_100

Mat100 (hexa): _SOLID

Mat196: _BEAM_196

This collector is later referenced as the weld element set while creating the groups (contact) definition.

| • | This script will create the following properties/materials collectors: |

| - | M_^<id1_id2>_< MAT100 or MAT196> or M_^_1W_<id1_id2_id3>_<MAT100 or MAT196>: These material collectors are created upon the selection of the configuration type by you with the MAT100 or the MAT196 card. The values for the cards are read from the *.ini file. These material collectors are referenced in the above created appropriate components. |

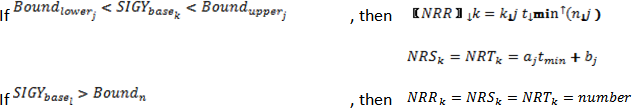

#MATERIAL STRENGTH LOOKUP TABLE

|

# FIRST NUMBER INDICATES NUMBER OF LEVELS

|

# SECOND NUMBER INDICATES MULTIPLIER FOR SIGY OF NUGGET

|

#MIN

|

MAX

|

k

|

n

|

a

|

b

|

|

#LAST LINE:

|

|

|

|

|

|

|

# MIN

|

MAX

|

k

|

n

|

a

|

b

|

NUMBER

|

*SIGY

|

4

|

1.85

|

|

|

|

|

0

|

0.20

|

4.0000

|

1.9000

|

10.5000

|

-4.000

|

|

0.20

|

0.40

|

4.2000

|

1.9500

|

12.000

|

-3.000

|

|

0.40

|

0.80

|

4.5000

|

1.9500

|

14.200

|

-2.000

|

|

0.80

|

0.90

|

4.7000

|

1.9900

|

16.500

|

-1.0000

|

9.00

|

|

| - | P_^<id1_id2>_<BEAM or SOLID> or P_^_1W<id1_id2_id3>_<BEAM or SOLID>: These property collectors are created with the *SECTION_BEAM or *SECTION_SOLID card associated with them. These property collectors are referenced in the above created appropriate components. |

# SAMPLE MATERIAL THICKNESS LOOKUP TABLE:

|

# NUMBER INDICATES NUMBER OF LEVELS

|

#LAST LINE:

|

*THICKNESS

|

5

|

|

|

|

|

|

0

|

0.1

|

0.125

|

|

|

|

|

0.1

|

0.5

|

.25

|

|

|

|

|

0.5

|

1.0

|

.75

|

|

|

|

|

1.0

|

1.5

|

1.25

|

|

|

|

|

1.5

|

2.0

|

17.75

|

2.0

|

|

|

|

| • | This script also creates the necessary group (contact) definition upon the selection of the configuration type. For mat100 and mat196 a group named C_Contact_Spotweld_<group id> and/or for mat100 (hexa) a group named C_Contact_Tied_Shell_Edge_To_Surface_<group id> is/are created. These interfaces are defined with the appropriate solver cards and reference the following master (MSID) and slave (SSID) sets: |

| - | For the *CONTACT_SPOTWELD_ID card the following FS and FD are set to 0.1. |

| - | For the *CONTACT_TIED_SHELL_EDGE_TO_SURFACE_ID card FS and FD are set to 0.1 as well. Additionally the values for variable SST and MST in the card image are set to 0.010. These values will override the thickness and establish the tied connection. |

| • | The script creates sets by the name C_S_^Part_<set id>_Contact_<group id> and C_S_^Weld_<set id>_Contact_<group id>. The configuration types mat100 and mat196 share the same sets, while the configuration type mat100 (hexa) gets a different pair of sets. The former set contains the parts to which the welds are connected and the latter contains the weld components created during realization process. The part sets is defined as master in the appropriate contact definition, the weld set as slave. |

In addition, for the mat100 (hexa) realization a set for each hexa cluster is created and named CE_HEXSW_<set id>.

All these sets get a card *DEFINE_HEX_SPOTWELD_ASSEMBLY_<# hexa> associated with them.

| Note: | This script is called if the CFG type is mat100/mat100 (hexa)/mat196 |

|

|

dyna mat100 (hexa)

The dyna mat100 (hexa) exists in exactly the same configuration with a HC hexa spotweld.

This is in order to keep the realization names from HyperCrash.

|

CFG dyna 101 mat100 (hexa)

*filter spot

*head

*body 0

hex8 1 1

*post prop_dyna_matnum.tcl

|

|

Description: Creates hexa element with plot elements projecting and connecting to the surrounding shell elements. This realization does not use the shell thickness to calculate the hexa offset, therefore the hexa will project and be touching the shell elements.

This realization also uses the prop_dyna_matnum.tcl property script.

This script is used while creation of mat100/mat100 (hexa)/mat196 custom config welds in the Spot panel. It does the following tasks.

| • | Organizes the realized weld elements to the respective components based upon the link they are connected to and based upon the realization used. |

If a weld is created as mat100 between comp_1(id1) and comp_2(id2), it will create a component collector with the name C_^_<id1_id2>_BEAM_100 and organize all of the welds created as links between these two components into this collector.

If a weld is created as mat100 between the three components comp_1(id1), comp_2(id2) and comp_3(id3), it will create two component collectors, C_^_1W_<id1_id2>_BEAM_100 and C_^_1W_<id2_id3>_BEAM_100. The suffix is based on the realization type:

Mat100: _BEAM_100

Mat100 (hexa): _SOLID

Mat196: _BEAM_196

This collector is later referenced as the weld element set while creating the groups (contact) definition.

| • | This script will create the following properties/materials collectors: |

| - | M_^<id1_id2>_< MAT100 or MAT196> or M_^_1W_<id1_id2_id3>_<MAT100 or MAT196>: These material collectors are created upon the selection of the configuration type by you with the MAT100 or the MAT196 card. The values for the cards are read from the *.ini file. These material collectors are referenced in the above created appropriate components. |

#MATERIAL STRENGTH LOOKUP TABLE

|

# FIRST NUMBER INDICATES NUMBER OF LEVELS

|

# SECOND NUMBER INDICATES MULTIPLIER FOR SIGY OF NUGGET

|

#MIN

|

MAX

|

k

|

n

|

a

|

b

|

|

#LAST LINE:

|

|

|

|

|

|

|

# MIN

|

MAX

|

k

|

n

|

a

|

b

|

NUMBER

|

*SIGY

|

4

|

1.85

|

|

|

|

|

0

|

0.20

|

4.0000

|

1.9000

|

10.5000

|

-4.000

|

|

0.20

|

0.40

|

4.2000

|

1.9500

|

12.000

|

-3.000

|

|

0.40

|

0.80

|

4.5000

|

1.9500

|

14.200

|

-2.000

|

|

0.80

|

0.90

|

4.7000

|

1.9900

|

16.500

|

-1.0000

|

9.00

|

|

| - | P_^<id1_id2>_<BEAM or SOLID> or P_^_1W<id1_id2_id3>_<BEAM or SOLID>: These property collectors are created with the *SECTION_BEAM or *SECTION_SOLID card associated with them. These property collectors are referenced in the above created appropriate components. |

# SAMPLE MATERIAL THICKNESS LOOKUP TABLE:

|

# NUMBER INDICATES NUMBER OF LEVELS

|

#LAST LINE:

|

*THICKNESS

|

5

|

|

|

|

|

|

0

|

0.1

|

0.125

|

|

|

|

|

0.1

|

0.5

|

.25

|

|

|

|

|

0.5

|

1.0

|

.75

|

|

|

|

|

1.0

|

1.5

|

1.25

|

|

|

|

|

1.5

|

2.0

|

17.75

|

2.0

|

|

|

|

| • | This script also creates the necessary group (contact) definition upon the selection of the configuration type. For mat100 and mat196 a group named C_Contact_Spotweld_<group id> and/or for mat100 (hexa) a group named C_Contact_Tied_Shell_Edge_To_Surface_<group id> is/are created. These interfaces are defined with the appropriate solver cards and reference the following master (MSID) and slave (SSID) sets: |

| - | For the *CONTACT_SPOTWELD_ID card the following FS and FD are set to 0.1. |

| - | For the *CONTACT_TIED_SHELL_EDGE_TO_SURFACE_ID card FS and FD are set to 0.1 as well. Additionally the values for variable SST and MST in the card image are set to 0.010. These values will override the thickness and establish the tied connection. |

| • | The script creates sets by the name C_S_^Part_<set id>_Contact_<group id> and C_S_^Weld_<set id>_Contact_<group id>. The configuration types mat100 and mat196 share the same sets, while the configuration type mat100 (hexa) gets a different pair of sets. The former set contains the parts to which the welds are connected and the latter contains the weld components created during realization process. The part sets is defined as master in the appropriate contact definition, the weld set as slave. |

In addition, for the mat100 (hexa) realization a set for each hexa cluster is created and named CE_HEXSW_<set id>.

All these sets get a card *DEFINE_HEX_SPOTWELD_ASSEMBLY_<# hexa> associated with them.

| Note: | This script is called if the CFG type is mat100/mat100 (hexa)/mat196. |

|

|

dyna mat196

CFG dyna 102 mat196

*filter spot

*head

*body 0

bar2 1 1

*post prop_dyna_matnum.tcl

|

|

Description: Creates a BEAM element for the body and plot elements for the head, the plot elements are created for visualization purposes and find operations. This realization is the same as the “CFG dyna 100 mat100” realization except it uses Mat196 as opposed to Mat100.

This realization also uses the prop_dyna_matnum.tcl property script.

This script is used while creation of mat100/mat100 (hexa)/mat196 custom config welds in the Spot panel. It does the following tasks.

| • | Organizes the realized weld elements to the respective components based upon the link they are connected to and based upon the realization used. |

If a weld is created as mat100 between comp_1(id1) and comp_2(id2), it will create a component collector with the name C_^_<id1_id2>_BEAM_100 and organize all of the welds created as links between these two components into this collector.

If a weld is created as mat100 between the three components comp_1(id1), comp_2(id2) and comp_3(id3), it will create two component collectors, C_^_1W_<id1_id2>_BEAM_100 and C_^_1W_<id2_id3>_BEAM_100. The suffix is based on the realization type:

Mat100: _BEAM_100

Mat100 (hexa): _SOLID

Mat196: _BEAM_196

This collector is later referenced as the weld element set while creating the groups (contact) definition.

| • | This script will create the following properties/materials collectors: |

| - | M_^<id1_id2>_< MAT100 or MAT196> or M_^_1W_<id1_id2_id3>_<MAT100 or MAT196>: These material collectors are created upon the selection of the configuration type by you with the MAT100 or the MAT196 card. The values for the cards are read from the *.ini file. These material collectors are referenced in the above created appropriate components. |

#MATERIAL STRENGTH LOOKUP TABLE

|

# FIRST NUMBER INDICATES NUMBER OF LEVELS

|

# SECOND NUMBER INDICATES MULTIPLIER FOR SIGY OF NUGGET

|

#MIN

|

MAX

|

k

|

n

|

a

|

b

|

|

#LAST LINE:

|

|

|

|

|

|

|

# MIN

|

MAX

|

k

|

n

|

a

|

b

|

NUMBER

|

*SIGY

|

4

|

1.85

|

|

|

|

|

0

|

0.20

|

4.0000

|

1.9000

|

10.5000

|

-4.000

|

|

0.20

|

0.40

|

4.2000

|

1.9500

|

12.000

|

-3.000

|

|

0.40

|

0.80

|

4.5000

|

1.9500

|

14.200

|

-2.000

|

|

0.80

|

0.90

|

4.7000

|

1.9900

|

16.500

|

-1.0000

|

9.00

|

|

| - | P_^<id1_id2>_<BEAM or SOLID> or P_^_1W<id1_id2_id3>_<BEAM or SOLID>: These property collectors are created with the *SECTION_BEAM or *SECTION_SOLID card associated with them. These property collectors are referenced in the above created appropriate components. |

# SAMPLE MATERIAL THICKNESS LOOKUP TABLE:

|

# NUMBER INDICATES NUMBER OF LEVELS

|

#LAST LINE:

|

*THICKNESS

|

5

|

|

|

|

|

|

0

|

0.1

|

0.125

|

|

|

|

|

0.1

|

0.5

|

.25

|

|

|

|

|

0.5

|

1.0

|

.75

|

|

|

|

|

1.0

|

1.5

|

1.25

|

|

|

|

|

1.5

|

2.0

|

17.75

|

2.0

|

|

|

|

| • | This script also creates the necessary group (contact) definition upon the selection of the configuration type. For mat100 and mat196 a group named C_Contact_Spotweld_<group id> and/or for mat100 (hexa) a group named C_Contact_Tied_Shell_Edge_To_Surface_<group id> is/are created. These interfaces are defined with the appropriate solver cards and reference the following master (MSID) and slave (SSID) sets: |

| - | For the *CONTACT_SPOTWELD_ID card the following FS and FD are set to 0.1. |

| - | For the *CONTACT_TIED_SHELL_EDGE_TO_SURFACE_ID card FS and FD are set to 0.1 as well. Additionally the values for variable SST and MST in the card image are set to 0.010. These values will override the thickness and establish the tied connection. |

| • | The script creates sets by the name C_S_^Part_<set id>_Contact_<group id> and C_S_^Weld_<set id>_Contact_<group id>. The configuration types mat100 and mat196 share the same sets, while the configuration type mat100 (hexa) gets a different pair of sets. The former set contains the parts to which the welds are connected and the latter contains the weld components created during realization process. The part sets is defined as master in the appropriate contact definition, the weld set as slave. |

In addition, for the mat100 (hexa) realization a set for each hexa cluster is created and named CE_HEXSW_<set id>.

All these sets get a card *DEFINE_HEX_SPOTWELD_ASSEMBLY_<# hexa> associated with them.

| Note: | This script is called if the CFG type is mat100/mat100 (hexa)/mat196. |

|

|

dyna hexa (tapered T)

CFG dyna 105 hexa (tapered T)

*filter seam

*style continuous 6

*head

*body 0

hex8 1 1

|

|

Description: Intended to be used for t-cases. The size and exact position can be defined thickness dependent, or the exact dimension and position parameters can be given.

|

dyna hexa (adhesive - shell gap)

The dyna hexa (adhesive - shell gap) exists in exactly the same configuration with the following additional names:

This is in order to keep the realization names from HyperCrash.

|

CFG dyna 106 hexa (adhesive - shell gap)

*filter seam

*style continuous 2

*head

*body 0

hex8 1 1

*post prop_dyna_matnum_seamarea.tcl

|

|

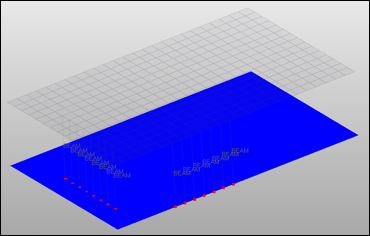

Description: This realization creates rows of HEXA elements for the body. The HEXA elements project and connect to the adjoining shell/solid elements by touching them.

The realization uses the prop_dyna_matnum_seamarea.tcl post script.

This script performs the following tasks:

| 1. | Creates NodesToSurface(Tied interfaces) and names them ADHESIVE_SEAM_CONTACT_PID _# , which references the independent/dependent links' master sets and the nodes' slave sets (# is the ID of the link components). |

| 2. | Organizes the link components into a set with name ADHESIVE_SEAM_MASTER_PART_SET_PID_#, which is referenced by the above interface group (# is the ID of the link component). |

| 3. | Organizes the solids‘ nodes on the links into a set with the name ADHESIVE_SEAM_SLAVE_NODE_SET_PID _#, which in turn is referenced by the above interface group (# is the ID of the link component). |

| 4. | Creates a component with the name ADHESIVE_SEAM_MAT100_COMP_PID_#_# for the connector SOLID elements (# is the ID of the link component). |

| 5. | Creates a property with the name ADHESIVE_SEAM_MAT100_PROP_PID _#_# and SectSld card image, and assigns it to the SOLID component (# is the ID of the link component). |

| 6. | Creates a material with the name ADHESIVE_SEAM_MAT100_MAT_PID_#_# and MATL100 card image, and assigns it to the SOLID component (# is the ID of the link component). |

|

| Note: | Uses the default parameters, material thickness lookup table, and material strength lookup table from the weld_config.ini config file to set the default attributes for the the created MATL100 material. |

|

dyna HC cylinder rigid bolt

CFG dyna 115 HC cylinder rigid bolt

*filter bolt

*style bolt 4

*head

*body 0

rigidlink 1 1

*post prop_dyna_rigidbolts.tcl

|

|

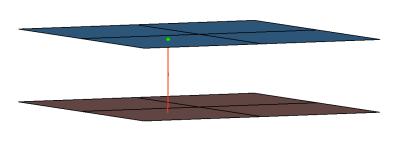

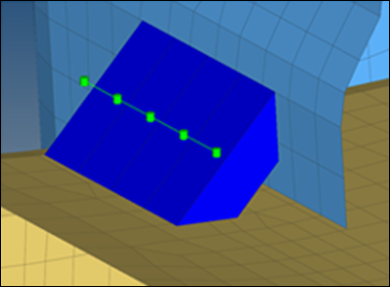

Description: This realization creates a single ConNode rigidlink element for the body, and projects and connects to nodes of the adjoining shell/solid within the prescribed cylinder diameter, L1 (cylinder height along the vector from the connector location) and L2 (cylinder height in the opposite direction of the vector from the connector location).

The realization uses the prop_dyna_rigidbolts.tcl property script.

The script performs the following tasks:

| 1. | Organizes the ConNode rigidlink elements into a component with the name Realize#001 (# starts with 2 and increments as 2, 4, 6, and so on for each new connector). |

| 2. | Creates a view with the name dyna_rigid_bolts. |

|

|

dyna adhesive (shell gap)

CFG dyna 116 HC cylinder spring bolt

*filter bolt

*style bolt 4

*head

rigidlink 1 1

*body 0

spring 1 1

*post prop_dyna_rigidbolts.tcl

|

|

Description: This realization creates a DISCRETE element for the body, and projects and connects to nodes of the adjoining shell/solid elements with ConNode rigidlink elements within the prescribed cylinder diameter, L1 (cylinder height along the vector from the connector location) and L2 (cylinder height in the opposite direction of the vector from the connector location).

The realization uses the prop_dyna_rigidbolts.tcl property script.

The script performs the following tasks:

| 1. | Organizes the DISCRETE element and the ConNode rigidlink elements into a component with name Realize#001 (# starts with 2 and increments as 2, 4, 6, and so on for each new connector). |

| 2. | Creates a view with the name dyna_rigid_bolts. |

|

|

dyna HC cylinder spring bolt

CFG dyna 121 adhesive (shell gap)

*filter area

*style adhesive 2

*head

*body 1

hex8 1 1

penta6 1 1

|

|

Description: Creates a row of hexa/penta elements. The hexa/penta elements are projected so that they touch the shell elements of the connecting components.

|

dyna - adhesive (shell gap)

CFG dyna 121 adhesive (shell gap)

*filter area

*style adhesive 1

*head

*body 1

hex8 1 1

penta6 1 1

*post prop_dyna_matnum_seamarea.tcl

|

|

Description: This realization creates rows of HEXA and PENTA elements for the body. The HEXA and PENTA elements project and connect to the adjoining shell/solid elements by touching them.

This realization uses the prop_dyna_matnum_seamarea.tcl post script.

This script performs the following tasks:

| 1. | Creates NodesToSurface(Tied interfaces) and names them ADHESIVE_AREA_CONTACT_PID _#, which references the independent/dependent links' master sets and the nodes' slave sets (# is the ID of the link components). |

| 2. | Organizes the link components into set a with the name ADHESIVE_AREA_MASTER_PART_SET_PID_#, which is referenced by the above interface group (# is the ID of the link component). |

| 3. | Organizes the solids‘ nodes on the links into a set with the name ADHESIVE_AREA_SLAVE_NODE_SET_PID _#, which in turn is referenced by the above interface group (# is the ID of the link component). |

| 4. | Creates a component with the name ADHESIVE_AREA_MAT100_COMP_PID_#_# for the connector SOLID elements (# is the ID of the link component). |

| 5. | Creates a property with the name ADHESIVE_AREA_MAT100_PROP_PID _#_# and the SectSld card image, and assigns it to the SOLID component (# is the ID of the link component). |

| 6. | Creates a material with the name ADHESIVE_AREA_MAT100_MAT_PID_#_# and MATL100 card image, and assigns it to the SOLID component (# is the ID of the link component). |

|

| Note: | Uses the default parameters, material thickness lookup table, and material strength lookup table from the weld_config.ini config file to set the default attributes for the the MATL100 material that was created. |

|

dyna - mat196 (single row)

CFG dyna 122 mat196 (single row)

*filter seam

*style continuous 4

*head

*body 0

bar2 1 0

*post prop_dyna_matnum_seamarea.tcl

|

|

Description: This realization creates a single row of BEAM elements for the body.

This realization uses the prop_dyna_matnum_seamarea.tcl post script and the weld_config.ini and init_dyna_mat196.ini config file.

The script performs the following tasks:

| 1. | Creates ContactSpotweld(interfaces) with the name BEAM_SEAM_CONTACT_PID _#, which references the independent/dependent links' master sets and the nodes' slave sets (# is the ID of the link components). |

| 2. | Organizes the link components into a set with the name BEAM_SEAM_MASTER_PART_SET_PID_#, which is referenced by the above interface group (# is the ID of the link component). |

| 3. | Organizes the beams‘ nodes on the links into a set with the name BEAM_SEAM_SLAVE_NODE_SET_PID _#, which in turn is referenced by the above interface group (# is the ID of the link component). |

| 4. | Creates a component with the name BEAM_SEAM_MAT196_COMP_PID_#_# for the connector BEAM elements (# is the ID of the link component). |

| 5. | Creates a property with the name BEAM_SEAM_MAT196_PROP_PID _#_# and the SectBeam card image, and assigns it to the BEAM component (# is the ID of the link component). |

| 6. | Creates a material with the name BEAM_SEAM_MAT196_MAT_PID_#_# and the MATL196 card image, and assigns it to the BEAM component (# is the ID of the link component). |

|

| Note: | Use the init_dyna_mat196.ini config file to set the default attributes for the created MATL196 material. |

|

Automatic Exclusion of Special Nodes During Rigid Bolt Realization

HyperMesh automatically excludes special nodes as potential slave nodes for any rigid bodies created during bolt realization, even though they fall with the virtual Bolt Cylinder diameter. Nodes that are shared by the following entities are considered special nodes:

| • | Nodes inside the Interfaces with Type2 |