18.2 - Square Membrane Elastic |

|

|

|

|

|

18.2 - Square Membrane Elastic |

|

|

|

|

TitleSquare membrane elastic |

|

||||||

Number18.2 |

|||||||

Brief DescriptionSquare plate submitted to two opposing in-plane end forces. |

|||||||

Keywords

|

|||||||

RADIOSS Options

|

|||||||

Input File4Q4: <install_directory>/demos/hwsolvers/radioss/18_Square_plate/Membrane_elastic/4Q4/.../TRACTION* 8T3: <install_directory>/demos/hwsolvers/radioss/18_Square_plate/Membrane_elastic/8T3/.../TRACTION* 8T3 inv: <install_directory>/demos/hwsolvers/radioss/18_Square_plate/Membrane_elastic/8T3_inv/.../TRACTION* 2Q4-4T3: <install_directory>/demos/hwsolvers/radioss/18_Square_plate/Membrane_elastic/2Q4-4T3/.../TRACTION* |

|||||||

Technical / Theoretical LevelBeginner |

|||||||

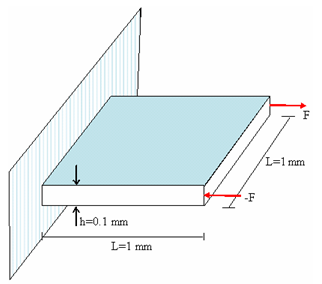

This example concerns the in-plane traction-comparison problem of an embedded plate subjected to two concentrated loads, as shown in the following diagram. This example illustrates the role of the different shell element formulations with regard to the mesh.

Units: mm, ms, g, N, MPa

The material used follows a linear elastic behavior and has the following characteristics:

| • | Initial density: 7.8 x 10-3 g/mm3 |

| • | Young modulus: 210000 MPa |

| • | Poisson ratio: 0.3 |

Fig 9: Geometry of the problem.

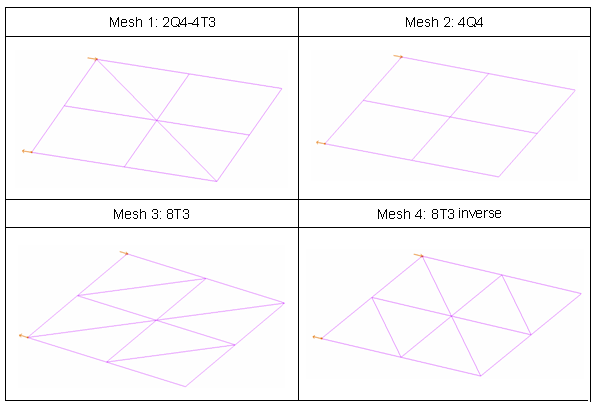

Four different types of mesh are used:

| • | Mesh 1: two quadrilateral shells and four triangular shells (2Q4-4T3) |

| • | Mesh 2: four quadrilateral shells (4Q4) |

| • | Mesh 3: eight triangular shells (8T3) |

| • | Mesh 4: eight triangular shells (8T3 inverse) |

For each model, the following shell formulations are tested:

| • | QBAT formulation (Ishell =12) |

| • | QEPH formulation (Ishell =24) |

| • | Belytshcko & Tsay formulation (Ishell =1 or 3, hourglass control type 1, 3) |

| • | C0 and DKT18 formulations |

Fig 10: Square plate meshes.

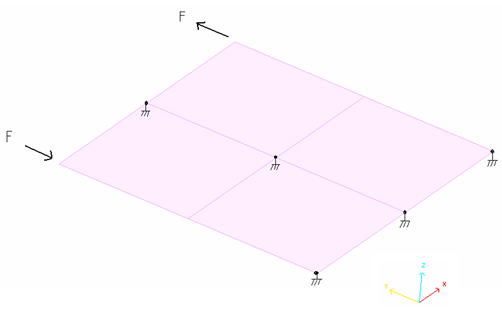

The boundary conditions are such that the three nodes of a single side and the two middle ones are blocked, whereas the others are free with respect to the Y axis.

Two concentrated loads are applied on the corner points on opposing sides. They increase over time, as defined by the following function:

F(t) |

0 |

10 |

10 |

t |

0 |

200 |

400 |

Fig 11: Boundary conditions and loads.

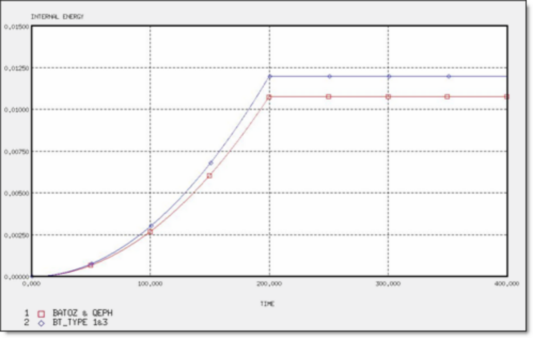

This example compares several models concerning:

| • | the use of different element formulations for each mesh |

| • | the different types of mesh for a given element formulation |

Two criteria used to compare the results are:

| • | absorbed energy (internal and hourglass) |

| • | vertical displacement of the node under the loading point |

The following diagrams summarize the results obtained.

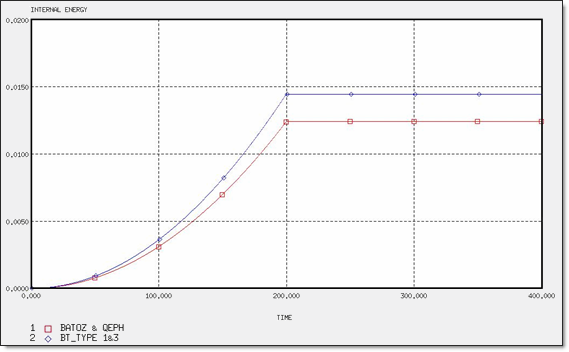

Fig 12: Internal energy for 2 x Q4 and 4 x T3 elements.

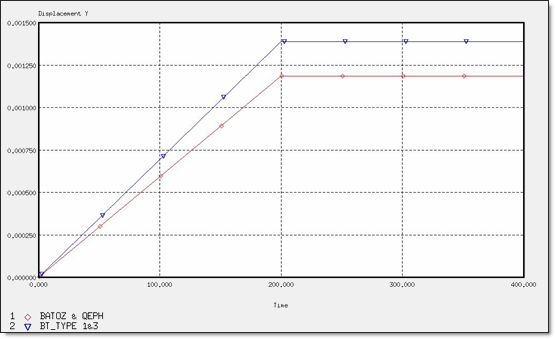

Fig 13: Y Displacement for 2 x Q4 and 4 x T3 elements

Fig 14: Internal energy for 4 x Q4 elements.

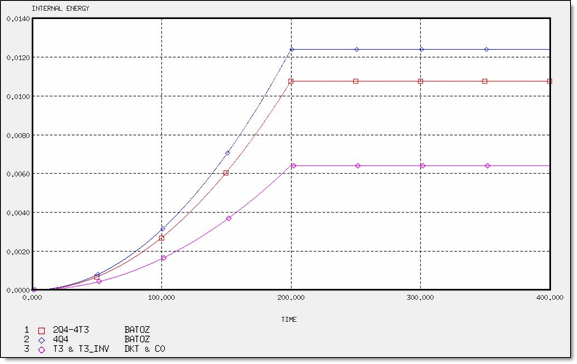

Fig 15: Internal energy for different meshes.

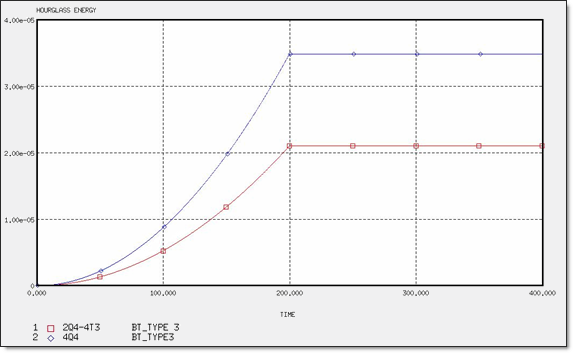

Fig 16: Hourglass energy for different meshes.

Elastic |

2Q4-4T3 |

4Q4 |

8T3 |

8T3_INV |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

QEPH |

BT_TYPE 1 and 3 |

BATOZ |

QEPH |

BT_TYPE 1 and 3 |

BATOZ |

DKT |

CO |

DKT |

CO |

|

IEmax |

1.07 x 10-2 |

1.19 x 10-2 |

1.07 x 10-2 |

1.24 x 10-2 |

1.44 x 10-2 |

1.24 x 10-2 |

6.42 x 10-3 |

6.42 x 10-3 |

6.42 x 10-3 |

6.42 x 10-3 |

HEmax |

--- |

2.10 x 10-5 |

--- |

--- |

3.49 x 10-6 |

--- |

--- |

--- |

--- |

--- |

Dymax |

1.18 x 10-3 |

1.38 x 10-3 |

1.18 x 10-3 |

1.24 x 10-3 |

1.44 x 10-3 |

1.24 x 10-3 |

6.42 x 10-3 |

6.42 x 10-3 |

6.42 x 10-3 |

6.42 x 10-3 |

In the case of elastic flat plate modeling, when the loading is in-plane, the shell elements are reduced to become a membrane if the loads applied do not cause buckling.

A general overview of the results obtained highlight the following key points:

| 1. | The quadrilateral shell elements QEPH and QBAT have the same in-plane behavior. |

| 2. | The different types of hourglass formulations in the BT shell elements lead to the same results, as there is no out-of-plane deformation and the material is supposed to be elastic. |

| 3. | The three in-plane behaviors of the DKT18 and T3C0 RADIOSS triangles are exactly the same, as both of the elements are used for the same membrane formulation. |

| 4. | The triangles are stiffer than the quadrilateral elements and do not provide good results, especially when the mesh is coarse. |

Refer to the RADIOSS Theory Manual for more details.