Ityp = 1 |

|

|

|

|

|

Ityp = 1 |

|

|

|

|

Block Format Keyword

/MAT/B-K-EPS - ITYP=1 - Boundary Conditions Material for Flow Analysis with Turbulence

Description

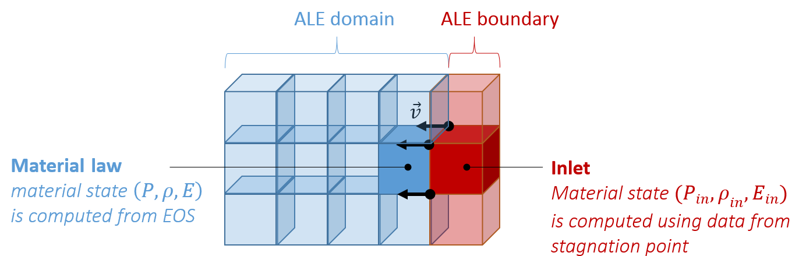

This law enables to model a liquid inlet condition by providing data from stagnation point. Liquid behavior is modeled with linear EOS. Input card is similar to /MAT/LAW11 (BOUND), but introduces two new lines to define turbulence parameters.

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

/MAT/B-K-EPS/mat_ID |

|||||||||

mat_title |

|||||||||

|

|

|

|

|

|

|

|

||

Ityp |

|

Psh |

FscaleT |

|

|

|

|

||

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

|---|---|---|---|---|---|---|---|---|---|

node_IDv |

|

C1 |

|

|

Cd |

|

|

||

fct_IDρ |

|

|

|

|

|

|

|

|

|

fct_IDp |

|

|

|

|

|

|

|

|

|

fct_IDE |

|

|

|

|

|

|

|

|

|

|

|

fct_IDk |

fct_IDε |

|

|

|

|

||

c |

|

|

Pr / Prt |

|

|

||||

fct_IDT |

fct_IDQ |

|

|

|

|

|

|

|

|

|

This leads to inlet state:

Specific volume energy E is defined as E = Eint / V, where Eint is the internal energy. It can be output using /TH/BRIC. Specific mass energy e is defined as e = Eint / m. This leads to |

See Also: