Drawbead Interface (/INTER/TYPE8) |

|

|

|

|

|

Drawbead Interface (/INTER/TYPE8) |

|

|

|

|

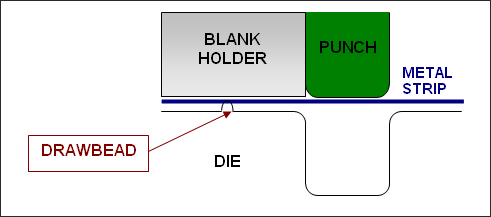

Interface type 8 is used to simulate drawbeads. This interface is mainly used in the process industry to model metal forming. Drawbeads are used to prevent the metal strip from sliding during the stamping process (Fig. 5.29).

Fig. 5.29: Stamping process

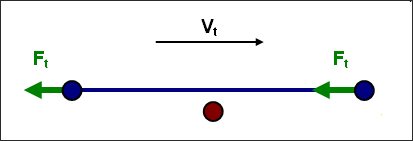

The modeling of the drawbeads using interface type 8, consists in defining a line of slave nodes and a master surface. The set of slave nodes must be sorted since the input force is a force per unit length, and the length is computed as the distance between two successive slave nodes. As soon as a slave node projects onto a master surface, a tangential force is applied to all master nodes to counter their tangential velocity (Fig. 5.30). Consequently the metal strip does not slide.

Fig. 5.30: Drawbead force

|

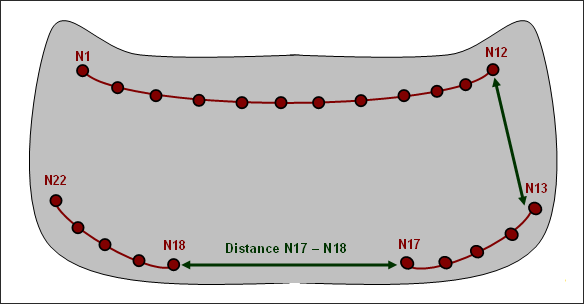

In case the drawbead is not continuous, it is necessary to create several type 8 interfaces, one interface for each continuous drawbead. Otherwise, the drawbead force can be far too high between two successive nodes that are not part of the same continuous drawbead.

The following example (Fig. 5.31) illustrates this point. The grey part could be a car hood, and three drawbeads are needed during the stamping process. If only one interface type 8 is created, as the drawbeads are not continuous, the distance between node N17 and N18 is much larger than the average distance between two successive nodes. Therefore, the drawbead force applied to nodes N17 and N18 could be too high, leading to unrealistic deformation in these areas.

Fig. 5.31: Example of hood stamping