Example 11 - Tensile Test |

|

|

|

|

|

Example 11 - Tensile Test |

|

|

|

|

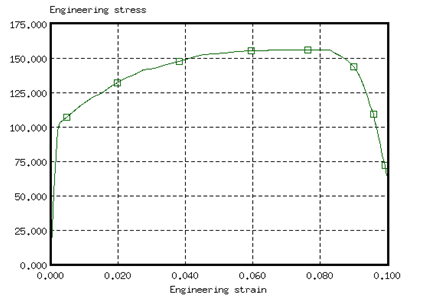

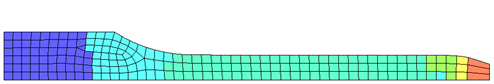

The material characterization of ductile aluminum alloy is studied. The RADIOSS material laws 2, 27 and 36 are used to reproduce the experimental data of a traction test by simulation. The work-hardening, damage and rupture of the object are simulated by a finite element model. The parameters of the material laws are determined to fit the experimental results. The influence of the strain rate is also studied. A strain rate filtering method is used to reduce the effect of a dynamic resolution on the simulation results.