Optimization of a Two-Layer Stamped Control Arm |

|

|

|

|

|

Optimization of a Two-Layer Stamped Control Arm |

|

|

|

|

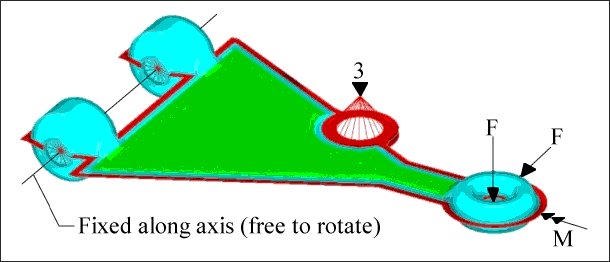

In this example, an automobile control arm is manufactured by using two stamped plates joined at the seam. The shape of the bead reinforcements on the plates is optimized to withstand the applied loads. The part is modeled as two layers of shell elements (green and blue) connected with fringe elements (red), as shown in the figure below. The model is pinned, but is free to rotate about an axis at the frame attachments. A vertical constraint is placed at the shock absorber attachment point. This point is connected to the fringe elements with rigid bars. Vertical, lateral, and twisting loads are applied to the spindle attachment.

Loads and constraints for the stamped control arm model.

The elements shown in green are included in the design space. The nodes in the top layer can move upward and the nodes on the bottom layer can move downward. Symmetry is used to force the bead pattern on the top to match the one on the bottom. The DTPG card is generated as follows:

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

DTPG |

2 |

DVGRID |

1 |

|

|

|

|

|

|

+ |

15.0 |

60.0 |

YES |

|

|

|

|

|

|

|

PATRN |

10 |

4184 |

|

|

1211 |

|

|

|

The plane of symmetry is normal to the vertical axis and is positioned running through the center plane of the model.

The optimization objective function is simply defined as minimizing the sum of the weighted compliance of all three load cases.

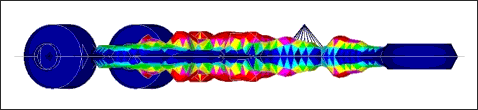

The solution for the model is shown in the figures below. The first figure shows the symmetry of the solution about the vertical axis.

OptiStruct solution for the stamped control arm model, side view.

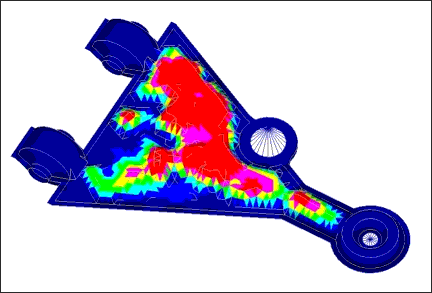

OptiStruct solution for the stamped control arm, top view.

The solution shows the importance of adding vertical bending stiffness in the area around the shock absorber attachment point. OptiStruct creates a large bead running from the upper frame attachment point, past the shock attachment, and up to the spindle attachment (second figure). This bead supports most of the bending load. In addition, there is vertical bending which runs in the perpendicular direction. OptiStruct creates a bead running from the shock attachment point to the lower frame attachment (second figure). This second bead is not as pronounced because there is less bending in that direction compared to the primary direction.

For the input file sample, see <install_directory>/demos/hwsolvers/optistruct/stampedarm.fem.

See Also: