RD-3550: Simplified Car Front Pole Impact |

|

|

|

|

|

RD-3550: Simplified Car Front Pole Impact |

|

|

|

|

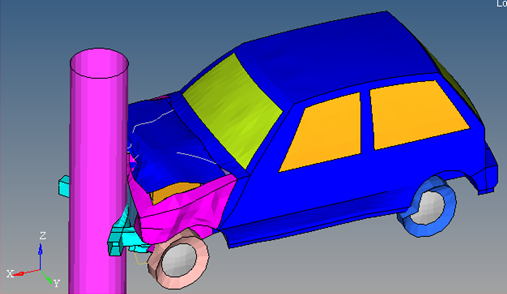

This tutorial demonstrates how to simulate frontal pole test with a simplified full car.

| • | UNITS: Length (mm), Time (s), Mass (ton), Force (N) and Stress (MPa) |

| • | Simulation time: Engine file (_0001.rad) [0 – 0.0601 ms] |

| • | An initial velocity of 15600 mm/s is applied on the car model to impact a rigid pole of radius 250 mm. |

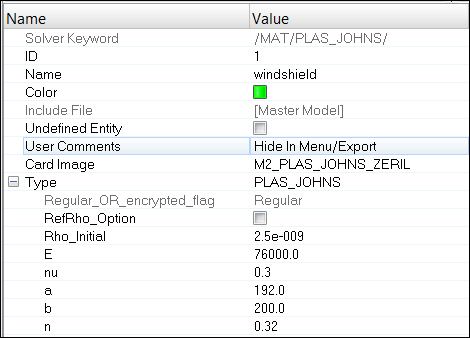

| • | Elasto-plastic Material /MAT/LAW2 (Windshield) |

[Rho_I] Initial Density = 2.5x10-9 ton/mm3

[E] Young's Modulus = 76000 MPa

[nu] Poisson’s Ratio = 0.3

[a] Yield Stress = 192 MPa

[b] Hardening Parameter = 200 MPa

[n] Hardening Exponent = 0.32

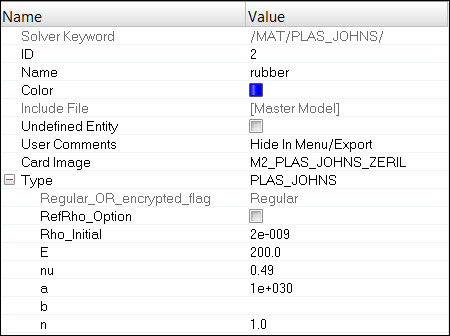

| • | Elasto-plastic Material /MAT/LAW2 (Rubber) |

[Rho_I] Initial Density = 2x10-9 ton/mm3

[E] Young's Modulus = 200 MPa

[nu] Poisson’s Ratio = 0.49

[a] Yield Stress = 1e30 MPa

[n] Hardening Exponent = 1

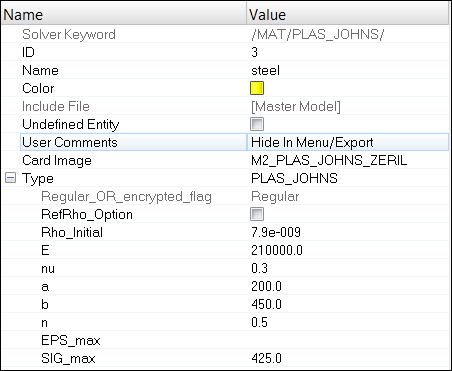

| • | Elasto-plastic Material /MAT/LAW2 (Steel) |

[Rho_I] Initial Density = 7.9x10-9 ton/mm3

[E] Young's Modulus = 210000 MPa

[nu] Poisson’s Ratio = 0.3

[a] Yield Stress = 200 MPa

[b] Hardening Parameter = 450 MPa

[n] Hardening Exponent = 0.5

[SIG_max] Maximum Stress = 425 MPa

Step 1: Load the RADIOSS User Profile

| 1. | Launch HyperMesh Desktop. |

| 2. | From the Preferences menu, select the User Profiles or click the |

| 3. | Select RADIOSS (Block140) and click OK. |

Step 2: Load the solver deck

| 1. | Click the Open Model icon |

| 2. | Click Open. |

The model loads into the graphics area.

Step 3: Create and assign the material for the windshield components

| 1. | In the Model browser, right-click and select Create > Material. The Entity Editor is displayed below the Model browser. |

| 2. | For Name, enter windshield. |

| 3. | Set Card Image as M2_PLAS_JOHNS_ZERIL and click Yes to confirm. |

| 4. | Input the values, as shown below: |

| 5. | In the Model browser, select components COMP-PSHELL_3 and COMP-PSHELL_16. |

| 6. | Click Mat_Id in the EE, select the material windshield and click OK to update the selected components with the created material. |

Step 4: Create and assign the material for the rubber components

| 1. | In the Model browser, right-click and select Create > Material. The Entity Editor is displayed. |

| 2. | For Name, enter rubber. |

| 3. | Set Card Image to M2_PLAS_JOHNS_ZERIL and click Yes to confirm. |

| 4. | Input the values, as shown below: |

| 5. | In the Model browser, select components COMP-PSHELL_20 through COMP-PSHELL_23. |

| 6. | For Mat_Id, select the material rubber and click OK to update the selected components with the created material. |

Step 5: Create Steel material and assign to all other parts

| 1. | In the Model browser, right-click and select Create > Material. The Entity Editor is displayed. |

| 2. | For Name, enter steel. |

| 3. | Set Card Image to M2_PLAS_JOHNS_ZERIL. |

| 4. | Input the values, as shown below: |

| 5. | In the Model browser select all components labeled with COMP-PSHELL and COMP-PROD, except COMP-PSHELL_3, COMP-PSHELL_16 and COMP-PSHELL_20 to COMP-PSHELL_23. |

| 6. | For Mat_Id, select the material steel and click OK to assign the material to the selected components. |

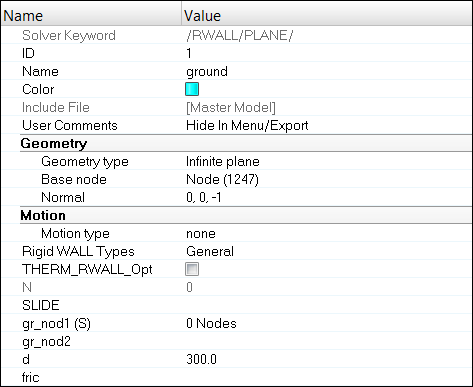

Step 6: Create a Rigid Wall

| 1. | In the Model browser, right-click and select Create > Rigid Wall. The Entity Editor is displayed. |

| 2. | For Name, enter ground. |

| 3. | Set Geometry type as Infinite plane. |

| 4. | Click Base node and select 'any node' from the model. |

| 5. | Define the normal vector Z = -1. |

| 6. | Set distance d = 300. |

| 7. | Go to the Analysis > rigid walls panel. |

| 8. | Move to the geom page. |

| 9. | Click name and select Ground from the list. |

| 10. | Click the edit tab besides base node and change values of the coordinates as indicated below. |

X = -2300, Y = 1200, and Z = -1.

| 11. | Click update > return. |

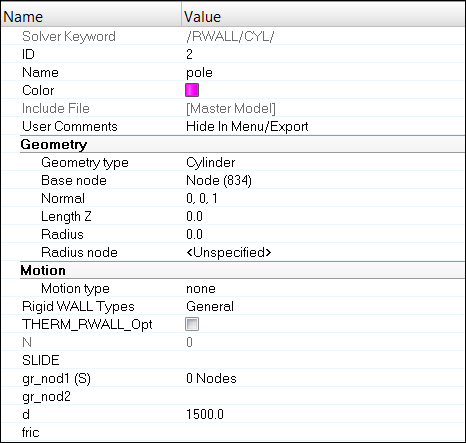

Step 7: Create a Cylindrical Rigid Wall to represent pole

| 1. | In the Model browser, right-click and select Create > Rigid Wall. The Entity Editor will display. |

| 2. | For Name, enter pole. |

| 3. | Set the Geometry type as Cylinder. |

| 4. | Click Base node and select ‘any node’ from the model. |

| 5. | Define the normal vector Z= 1. |

| 6. | For Radius node, do not select anything. Leave it as <Unspecified>. |

| 7. | Set distance d= 1500. |

| 8. | Go to Analysis > Rigid Walls panel. |

| 9. | Move to the geom page. |

| 10. | Click name and select Pole from the list. |

| 11. | Click the edit tab besides base node and change values of the coordinates as indicated below. |

X = -320, Y = 1250, and Z = 0.

| 12. | Set Radius = 250. |

| 13. | Click update > return. |

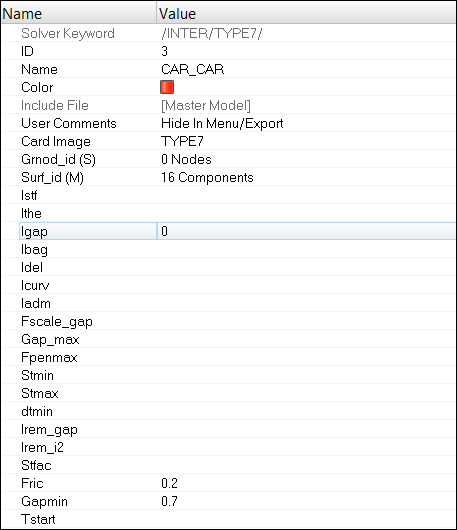

Step 8: Defining Contact using TYPE 7 interface (Self Contact)

| 1. | Hide all the 1D (TRUSSES) and 3D (SOLID) parts in the model by going to the Solver browser PROP > SHELL, Isolate only. Return to the Model browser. |

| 2. | In the Model browser, right-click and select Create > Contact. The Entity Editor will display. |

| 3. | For Name, enter CAR_CAR. |

| 4. | Set Card Image to TYPE7 and click Yes to confirm. |

| 5. | For Surf_id (M) (master entity), set the option to Components and select displayed components and click OK. |

| 6. | Input other parameters, as shown below. |

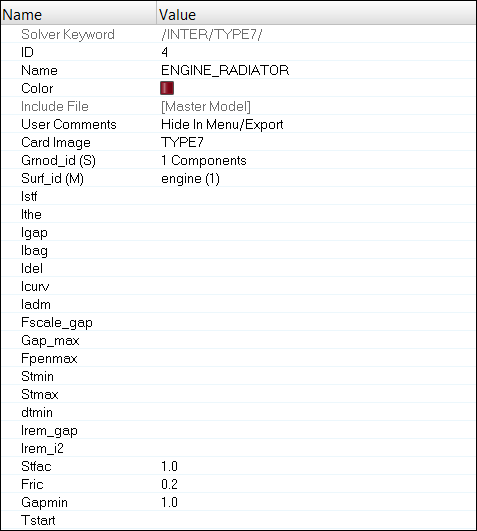

Step 9: Defining Contact using TYPE 7 interface between Engine and Radiator

| 1. | In the Solver browser, right-click and select Create > SURF_EXT > PART. |

| 2. | For Name, enter engine. |

| 3. | Click on Components and select COMP-PSOLID_24. |

| 4. | In the Model browser, right-click and select Create > Contact. |

| 5. | For Name, enter ENGINE_RADIATOR and set the Card Image as TYPE7 and click Yes to confirm. |

| 6. | For Grnod_id (S) (slave entity), set the selector switch to Components and click Components, select COMP-PSOLID_26. |

| 7. | For Surf_id (M) (master entity), set the selector switch to Set and click Set, select engine. |

| 8. | Input the values, as shown below: |

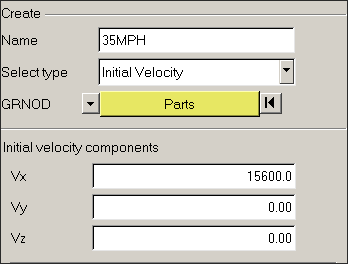

Step 10: Defining initial velocity

| 1. | Click Tools > BCs Manager to start the BCS Manager. |

| 2. | For Name, enter 35MPH, set Select type as Initial Velocity and set GRNOD to Parts. |

| 3. | Click comps and select all of the parts in the model. |

| 4. | Set the Vx as 15600. |

| 5. | Click Create to create the boundary condition and boundary condition appears in the table. |

| 6. | Click Close. |

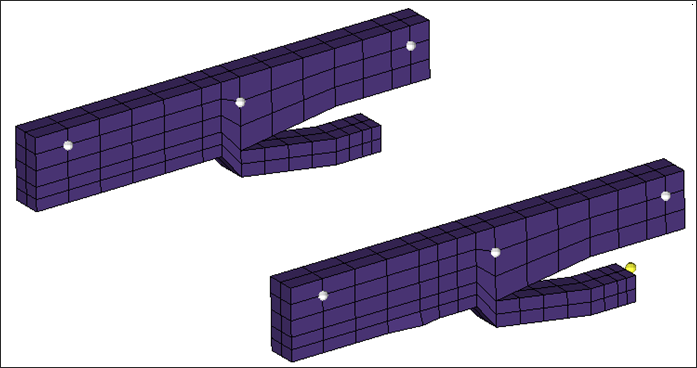

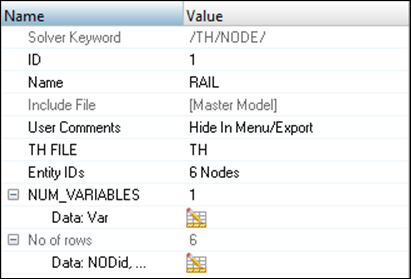

Step 11: Create Time History Nodes

| 1. | In the Model browser, isolate COMP-PSHELL_19. |

| 2. | Click Tools > Create Cards > TH > NODE. |

| 3. | For Name, enter RAIL and select nodes on the Rail, as shown below. |

| 4. | For NUM_VARIABLES, select 1 and for Data: Var, enter the following: |

Step 12: Create output requests and control cards

| 1. | Launch the HyperMesh Solver browser from View > Browsers > HyperMesh > Solver. |

| 2. | Right-click in the Solver browser general area to create the cards shown below with the given values for each parameter: |

Keyword Type |

Keyword |

Parameter |

Parameter Value |

|---|---|---|---|

CONTROL CARDS |

TITLE |

Status |

[Checked] |

CONTROL CARDS |

TITLE |

TITLE |

Car_Analysis |

ENGINE KEYWORDS |

RUN |

Status |

[Checked] |

ENGINE KEYWORDS |

RUN |

Run Number |

1 |

ENGINE KEYWORDS |

RUN |

Tstop |

0.0601 |

ENGINE KEYWORDS |

Status |

[Checked] |

|

ENGINE KEYWORDS |

N_Print |

-1000 |

|

ENGINE KEYWORDS |

TFILE |

Status |

[Checked] |

ENGINE KEYWORDS |

TFILE |

Time Frequency |

9e-5 |

ENGINE KEYWORDS |

ANIM/ELEM |

Status |

[Checked] |

ENGINE KEYWORDS |

ANIM/ELEM |

EPSP |

[Checked] |

ENGINE KEYWORDS |

ANIM/ELEM |

VONM |

[Checked] |

ENGINE KEYWORDS |

ANIM/ELEM |

HOURG |

[Checked] |

ENGINE KEYWORDS |

ANIM/VECT |

Status |

[Checked] |

ENGINE KEYWORDS |

ANIM/VECT |

VEL |

[Checked] |

ENGINE KEYWORDS |

ANIM/VECT |

CONT |

[Checked] |

ENGINE KEYWORDS |

ANIM/VECT |

FOPT |

[Checked] |

ENGINE KEYWORDS |

ANIM/DT |

Status |

[Checked] |

ENGINE KEYWORDS |

ANIM/DT |

Tstart |

0 |

ENGINE KEYWORDS |

ANIM/DT |

Tfreq |

0.003 |

Step 13: Export the model

| 1. | Click File > Export or click the Export icon |

| 2. | Enter a filename in the destination directory where you want to export to. |

| 3. | Enter the name FULLCAR and click Save. |

| 4. | Click the downward-pointing arrows next to Export options to expand the panel. |

| 5. | Click Merge starter and engine file to export the engine file with the model in one file. |

| 6. | Click Export to export both model and engine file. |

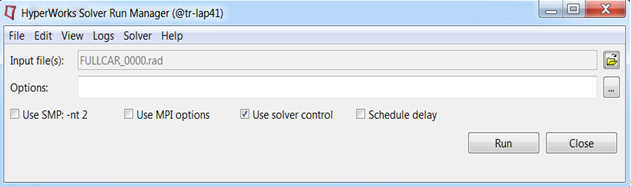

Step 14: Run the solver using RADIOSS Manager

| 1. | Go to Start > Programs > Altair HyperWorks 14.0 > RADIOSS. |

| 2. | For Input file, browse to the exercise folder and select the file FULLCAR_0000.rad. |

Step 15 (Optional): View the results in HyperView

The exercise is complete. Save your work to a HyperMesh file.

See Also: