Kinematics and Compliance |

|

|

|

|

|

Kinematics and Compliance |

|

|

|

|

The Kinematics and Compliance (K&C) test is performed by applying a range of vertical forces at the four contact patches of a vehicle to determine the suspension’s characteristics. The motion of the wheel caused by the force application is measured and recorded during this event. This in turn helps to determine suspension hard point locations, spring rates, bushing rates, arm lengths, etc.

Kinematics and Compliance Event

The entire event simulations lasts for 90 seconds and can be broken into four distinct sub-events:

| • | Ride |

| • | Roll |

| • | Contact patch force |

| • | Steer analysis |

The event begins with the ride analysis where in all wheels are subjected to a vertical displacement input through the jacks. The inputs have the same amplitude as those who are in phase. This part of the event lasts for 10 seconds.

Time in Seconds |

Action |

|---|---|

0 to 2.5 |

Wheels move from Design Position to Jounce Position. |

2.5 to 5.0 |

Wheels move from Jounce Position to Design Position. |

5.0 to 7.5 |

Wheels move from Design to Rebound Position. |

7.5 to 10.0 |

Wheels move from Rebound Position to Design Position. |

10.0 |

Event Ends. |

This event begins immediately after the ride event is complete. For this part of the event all wheels are subjected to a vertical displacement input through the jacks. The inputs amplitude is the same and with the left and right wheels being out of phase by 180 deg. This part of the event lasts for a duration of 10 seconds.

Time in Seconds |

Action |

|---|---|

10 to 12.5 |

Left Wheels move from Design Position to Jounce Position. Right wheels move from Design Position to Rebound Position. |

12.5 to 15.0 |

Left Wheels move from Jounce Position to Design Position. Right wheels move from Rebound Position to Design Position. |

15.0 to 17.5 |

Left Wheels move from Design Position to rebound Position. Right wheels move from Design Position to Jounce Position. |

17.5 to 20.0 |

Left Wheels move from rebound Position to Design Position. Right wheels move from Jounce Position to Design Position. |

20.0 |

Event Ends. |

This event begins immediately after the roll analysis is completed. This phase of the event evaluates the compliance of the suspension by simulating forces at the contact patch. For the first 20 seconds of this event, a lateral force is applied at the contact patch. The lateral force simulates cornering conditions. For the next 20 seconds, a longitudinal force is applied at the contact patch. The longitudinal force simulates braking and acceleration conditions. The third part of this event simulates moments about the wheel vertical by applying a torque about the wheel vertical axis. This part of the event lasts for 20 seconds.

Time in Seconds |

Action |

|---|---|

20 – 30 |

Lateral force is applied on all four contact patches in a parallel direction. |

30 - 40 |

Lateral force is applied on all four contact patches in an opposing direction. |

40 - 50 |

Longitudinal force is applied on all four contact patches along the X direction of the Global Origin to simulate a braking condition. |

50 – 60 |

Longitudinal force is applied on all four contact patches along the negative X direction of the Global Origin to simulate an acceleration condition. |

60 – 70 |

Aligning torque about the vertical axis (Global Z) is applied on all four contact patches about the same direction. |

70 – 80 |

Aligning torque about the vertical axis (Global Z) is applied on all four contact patches about opposing directions. |

80 |

Event ends. |

This final part of the kinematics and compliance analysis involves testing the front suspension kinematics when a steering input is applied. This part of the event lasts for 10 seconds with steering motion being in both directions.

Time in Seconds |

Action |

|---|---|

80 – 85 |

Steering motion is applied in the counter-clockwise direction. |

85 – 90 |

Steering motion is applied in the clockwise direction. |

90 |

Event ends. |

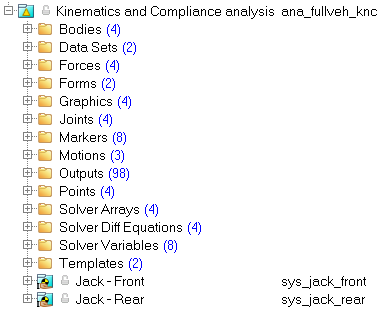

The entities in the event are displayed in the MotionView Project browser as shown in the image below:

Browser View - Forms - Straight Line Acceleration Analysis

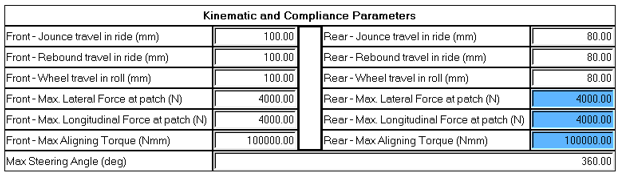

The inputs to the kinematics and compliance event are described in the table below:

Name |

Description |

Units |

|---|---|---|

Front jounce travel in ride |

The vertical input distance for the front wheels to travel in the upward direction relative to the ground in ride. |

mm |

Rear jounce travel in ride |

The vertical input distance for the rears wheels to travel in the upward direction relative to the ground in ride. |

mm |

Front rebound travel ride |

The vertical input distance for the front wheels to travel in the downward direction relative to the ground in ride. |

mm |

Rear rebound travel in ride |

The vertical input distance for the rear wheels to travel in the downward direction relative to the ground in ride. |

mm |

From wheel travel in roll |

The vertical input distance for the front wheels to travel in both directions relative to ground. |

mm |

Rear wheel travel in roll |

The vertical input distance for the rear wheels to travel in both directions relative to ground. |

mm |

Front wheel lateral force at contact patch |

The sideways force applied at the front wheel contact patch to simulate conditions experienced during cornering. |

N |

Rear wheel lateral force at contact patch |

The sideways force applied at the rear wheel contact patch to simulate conditions experienced during cornering. |

N |

Front wheel longitudinal force at contact patch |

The force applied along the length of the vehicle at the front wheel contact patch to simulate braking and acceleration. |

N |

Rear wheel longitudinal force at contact patch |

The force applied along the length of the vehicle at the rear wheel contact patch to simulate braking and acceleration. |

N |

Front aligning torque |

The torque applied about the front wheel vertical axis. |

N/mm |

Rear aligning torque |

The torque applied about the rear wheel vertical axis. |

N/mm |

Steering Angle |

The rotational input at the steering wheel to simulate cornering. |

deg |

K & C event - Inputs form

The event uses the standard event attachment described here. In addition to the standard attachments for full vehicle analysis it uses three more attachments.

Full Vehicle Event – Attachments

Kinematics and Compliance Event – Attachments |

The kinematics and compliance analysis for the full vehicle contains two datasets. One that takes the simulation parameters as input (as described in the table under Input Parameters). The second dataset, “Vehicle Parameters”, takes information about the vehicle as input and is used during the simulation. The Vehicle Parameters are described in the table below:

Project Browser View - Dataset "Full Vehicle Data"

Dialog View - Dataset "Full Vehicle Data" |

The kinematics and compliance event contains two forms:

Project Browser View - Form "Kinematics and Compliance"

Dialog view - Form “Kinematics and Compliance Parameters”

Dialog view - Form “Vehicle Parameters” |

The kinematics and compliance event consists of four graphics entities to represent the four jacks up on which the vehicle is hoisted with the four tires being in contact with the jack. The table below describes the graphics used in this event:

Graphical View - Graphics in “Kinematics and Compliance”

Project Browser View - Graphics - Kinematics and Compliance |

The kinematics and compliance event consists of eight joints. Four of these are contained within the sub-system for Jack Front and Jack Rear. The table below describes the joints used in detail:

Project Browser View - Joints - Kinematics and Compliance |

The kinematics and compliance event consists of eight markers:

Project Browser View - Markers - Kinematics and Compliance |

The kinematics & compliance event contains four points:

Project Browser View - Points - Kinematics and Compliance |

The kinematics and compliance event consists of eight solver variable entities:

Left Front command expression

Right Front command expression

Left Rear command variable

Right Rear command variable

Plots – Wheel Displacements for all four wheels based on the solver variable expressions

Project Browser View - Solver Variables - Kinematics and Compliance |

The full vehicle kinematics and compliance analysis consists of four solver differential entities:

Left Front Jack Diff expression in detailThe structure and logic for the four solver diff expressions are similar, the only difference being that they each use their respective solver variable values. The below uses the “Left front jack diff” as an example:

Project Browser View - Solver Differentials - Kinematics and Compliance |

The kinematics and compliance analysis consists of four solver arrays. A Vehicle Parameter Array each for the front and rear and a Testrig Parameter Array each for the front and rear. Vehicle Parameter arrayThe Vehicle Parameter array contains vehicle information that is used to calculate the SDF’s. Some of the data is also used in the analysis events to create point locations and forces. The data is entered in the Vehicle Parameter Form. T here are two vehicle parameter arrays: one for the front suspension and the other for the rear suspension.

Testrig Parameter ArrayThe testrig parameter array contains point, force and motion data, and is passed to the SDF subroutine and used to run the SDF calculation event. The testrig parameter array is symbolically defined and should not require editing. The event contains two testrig parameter arrays: one for the front suspension and the other for the rear suspension.

Project Browser View - Solver Array - Kinematics and Compliance |

The kinematics and compliance analysis consists of four force entities:

Project Browser View - Forces - Kinematics and Compliance |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The kinematics and compliance analysis consists of four joints. The table below describes the use of each joint.

Project Browser View - Joints - Kinematics and Compliance |

The kinematics and compliance analysis consists of three motions. The table below describes the use of each.

Project Browser View - Motions - Kinematics and Compliance |

The kinematics and compliance analysis consists of a total of 98 output entities. They can be broadly classified in to two groups: Static design factor outputs (SDFs) and non-SDFs. The SDF outputs are computed using a sub-routine that uses the SolverArrays defined in this event and are explained in detailed here <link to the SDF reference MDL doc>. The non-SDF outputs are described in the table below.

|

The kinematics and compliance analysis contains two templates. The first template, ”Full vehicle KnC”, defines three output file control statements, two static analysis blocks where entity states are modified and simulation begin and end times specified. The second template is deactivated by default and is used to turn on graphics in post animation for a few of the static design factors. This is currently an experimental feature. The table below describes the first template (“Full vehicle KnC”):

Project Browser View - Templates - Kinematics and Compliance |

The kinematics and compliance analysis contains two sub-systems that are instances from a single system definition – “Jack System”. The system contains two joints and three vectors. The joints connect the jack to ground and to the wheel. The vectors are parallel to the Global axes and are used as reference vectors. The graphics of the Jack are in the event template, which in this case is the ride event.

Project Browser View - Jack System Modeling Entities - Kinematics and Compliance Jack System JointsThere are two joint pairs in the Jack system. The first joint is the “Jack Trans jt”, which connects the Jack body to ground with a translational joint at the lower end of the jack body. The joint is oriented in the Z (vertical) direction. The joint forces the Jack to travel only in the vertical direction. Jack System VectorsThree vectors are defined along the Global X, Y, and Z axes. These vectors are used to orient certain joints in the model. |