Block Format Keyword

/MAT/LAW24 - Concrete Material

Description

This law is designed to model brittle elastic-plastic behavior of reinforced concrete. The law assumes that the two failure mechanisms are tensile cracking and compressive crushing of the concrete material. This keyword is compatible only with solid elements.

Format

(1)

|

(2)

|

(3)

|

(4)

|

(5)

|

(6)

|

(7)

|

(8)

|

(9)

|

(10)

|

/MAT/LAW24/mat_ID/unit_ID or /MAT/CONC/mat_ID/unit_ID

|

mat_title

|

|

|

|

|

|

|

|

|

|

Ec

|

|

|

|

|

|

|

|

fc

|

ft/fc

|

fb/fc

|

f2/fc

|

s0/fc

|

Ht

|

Dsup

|

|

|

|

|

|

ky

|

|

|

Hbp

|

|

|

|

|

vmax

|

|

|

|

|

fk

|

f0

|

Hv0

|

|

|

|

|

E

|

|

Et

|

|

|

|

|

|

|

|

|

|

|

|

Field

|

Contents

|

SI Unit Example

|

mat_ID

|

Material identifier

(Integer, maximum 10 digits)

|

|

unit_ID

|

Optional unit identifier

(Integer, maximum 10 digits)

|

|

mat_title

|

Material title

(Character, maximum 100 characters)

|

|

|

Initial density

(Real)

|

|

Ec

|

Concrete elasticity Young’s modulus

(Real)

|

|

|

Poisson’s ratio

(Real)

|

|

fc

|

Concrete uniaxial compression strength

(Real)

|

|

ft/fc

|

Concrete tensile strength ratio

Default = 0.10 (Real)

|

|

fb/fc

|

Concrete biaxial strength ratio

Default = 1.20 (Real)

|

|

f2/fc

|

Concrete confined strength ratio

Default = 4.00 (Real)

|

|

s0/fc

|

Concrete confining stress ratio

Default = 1.25 (Real)

|

|

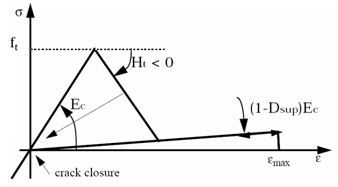

Ht

|

Concrete tensile tangent modulus

Default = -Ec (Real)

|

|

Dsup

|

Concrete maximum damage

Default = 0.99999 (Real)

|

|

max max

|

Concrete data total failure strain

Default = 1030 (Real)

|

|

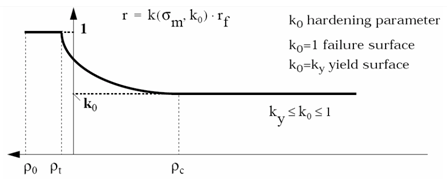

ky

|

Concrete plasticity initial value of hardening parameter (first part)

Default = 0.5 (Real)

|

|

|

Concrete plasticity failure/plastic transition pressure (first part)

Default = 0.0 (Real)

|

|

|

Concrete plasticity proportional yield transition pressure (first part)

Default = -fc/3 (Real)

|

|

Hbp

|

Concrete plasticity base plastic modulus (first part)

Default is computed by Starter (Real)

|

|

|

Concrete plasticity dilatancy factor at yield (second part)

Default = 0.0 (Real)

|

|

|

Concrete plasticity dilatancy factor at failure (second part)

Default = 0.0 (Real)

|

|

vmax

|

Concrete plasticity maximum volumetric compaction ( < 0 ) (second part)

Default = -0.35 (Real)

|

|

fk

|

Initial beginning of cap

Default = -fc/3 (Real)

|

|

f0

|

Initial end of cap

Default = -0.8 fc (Real)

|

|

Hv0

|

Initial triaxial plastic modulus

Default = 0.2 Ec (Real)

|

|

E

|

Steel properties Young’s modulus

(Real)

|

|

|

Yield strength

(Real)

|

|

Et

|

Tangent modulus

(Real)

|

|

|

Steel percentage ratio of reinforcement in direction 1

(Real)

|

|

|

Steel percentage ratio of reinforcement in direction 2

(Real)

|

|

|

Steel percentage ratio of reinforcement in direction 3

(Real)

|

|

|

#RADIOSS STARTER

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/CONC/1/1

concrete - air dry

# RHO_I

.0024

# E_c NU

41200 .2

# fc ft_on_fc fb_on_fc f2_on_fc s0_on_fc

44 0 0 0 0

# H_t D_sup EPS_max

0 0 0

# k_y r_t r_c H_bp

0 0 0 0

# ALPHA_y ALPHA_F V_max

0 0 0

# f_k f_0 H_v0

0 0 0

# E sigma_y E_t

0 0 0

# ALPHA1 ALPHA2 ALPHA3

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

|

| 1. | This material law can be used with only four parameters:  , Ec, , Ec,  , and fc. Default values are consistent with generic concrete type material. , and fc. Default values are consistent with generic concrete type material. |

| 2. | The 10-node tetrahedron elements are compatible with this law. |

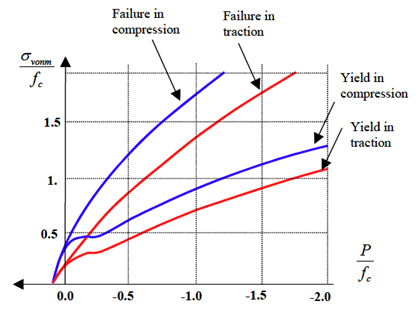

| 4. | The yield envelope is derived from the failure envelope with a scale factor k( m, k0). m, k0). |

Where, fc is the uniaxial compression strength.

Strain-stress relation in uniaxial tension test.

| 6. | For reinforcement in each direction, you provide the ratio of reinforcement (for example, for a reinforcement of 6%, input 0.06). |

| 7. | Reinforcement behavior is elastic plastic with hardening. |

| 8. | Steel directions must be given in property set type 6. Otherwise, the local element coordinate r, s, and t are taken respectively as directions 1, 2, and 3; unless Isolid = 1 or 2 with Iframe = 2; in which case the orthotropic directions 1, 2 and 3 are defined with the local co-rotating element coordinate r, s, and t, where time = 0. Law Concrete (24), Isolid = 12 with Iframe = 2 and Solid (14) property set cannot be used simultaneously. |

| 9. | In axisymmetrical analysis, direction 3 is the  direction. direction. |

Warning: The default values of dilatancy parameters  and and  are modified in RADIOSS V14.0 to assure better stability of results. These parameters should be negative and recommended values are -0.2 and -0.1, respectively. are modified in RADIOSS V14.0 to assure better stability of results. These parameters should be negative and recommended values are -0.2 and -0.1, respectively.

|

See Also:

Material Compatibility

Law Compatibility with Failure Model

/MAT/LAW24 in Theory Manual

Example 47 - Concrete Validation