Symmetric Interface (/INTER/TYPE3) |

|

|

|

|

|

Symmetric Interface (/INTER/TYPE3) |

|

|

|

|

This interface is used to simulate symmetric impacts between two surfaces. Both surfaces are defined through the use of oriented segments; therefore contacts can only occur on one side. Each node on both surfaces is considered as a slave node, and each surface is considered as a master segment.

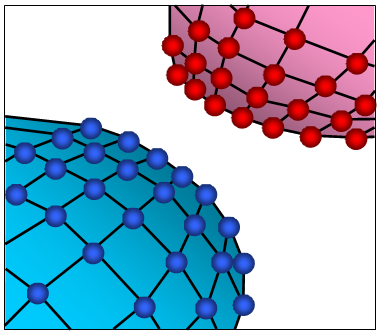

Fig. 5.5: Interface type 3

Contrary to interface type 5, interface type 3 has two master surfaces, therefore the contact algorithm is performed twice. The first pass solves the penetration of nodes from the first surface with respect of the second surface. The second pass solves the penetration of nodes from the second surface with respect of the first surface. This leads to higher accuracy compared to interface type 5, but more CPU time is needed.

When contact is detected, an elastic spring is added and the spring stiffness is calculated using both surfaces stiffness. Based on material and geometric properties, stiffness is attributed to each surface, then the overall interface stiffness is computed:

The default value for the stiffness scale factor(s) is 0.2, for stability reason this value should not be modified. However, if the ratio of K1 over K2 is greater than 100 (or lower than 0.01), it is recommended to increase the stiffness scale factor to avoid too many penetrations. The spring stiffness is constant, allowing slave nodes to pass through the mid-plane of the master segment.

This interface does not enable auto-contact simulation, as a node cannot belong to both surfaces.

|