Friction |

|

|

|

|

|

Friction |

|

|

|

|

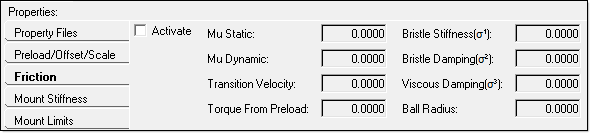

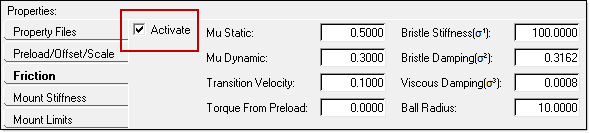

Select the Friction tab and the following appears:

You can enable friction torque by checking Activate:

The friction torque resists rotation of the bodies relative to one another. The friction model supports stiction and sliding effects as well as a measured friction torque due to preload in the bushing. The friction model is based on the LuGre model (References 2. and 3).

The following table describes the properties on the Friction tab. Abbreviations are: [F] = force, [L] = length, [T] = time.

Option |

Dimension |

Description |

||||||

Activate |

NA |

Check the activate box to compute the friction torque for the bushing. When friction is active, MotionView adds to your model a control state equation and other elements that MotionSolve requires to compute the friction torque. |

||||||

Mu-Static |

No Units |

Enter a positive real value giving the coefficient of static friction (μs). |

||||||

Mu-Dynamic |

No Units |

Enter a positive real value giving the coefficient of dynamic (sliding) friction (μd). (μd) ≤ (μs). |

||||||

Transition Velocity |

[L][T-1] |

Enter a positive real value giving the relative velocity (Vs) on the surface of the ball at which the transition from static to dynamic (sliding) friction is complete (for example, μ=μd). |

||||||

Bristle Stiffness (σ0) |

[L-1] |

Enter a positive real value for bristle stiffness. The bristle stiffness along with the coefficient of friction (μ), ball radius (Rb) and normal force (N) determines effective torsion stiffness (Kt) of the friction: |

||||||

Bristle Damping(σ1) |

[T][L-1] |

Enter a positive real value giving the bristle damping coefficient of the Lugre model. The bristle damping coefficient acts on the rate-of-change of bristle deflection, which is an internal friction state dependent on the sliding velocity and bristle deflection. |

||||||

Viscous Damping (σ2) |

[T][L-1] |

Enter a positive real value giving the viscous damping coefficient of the Lugre model. The viscous damping coefficient acts on the sliding velocity. |

||||||

Torque Preload |

[F][L][T-1] |

Enter a positive real value giving the friction torque due to preload. This value is typically the friction torque measured in the bushing with no external loads applied to the bushing. The friction torque arises from preload (internal loads) created when manufacturing or installing the bushing. |

||||||

Ball Radius |

[L] |

Enter a positive real value for the ball radius(Rb). The friction model assumes that the bushing acts like a spherical joint and the friction arises at the contact point between the ball and socket. For a given normal force (N) in the bushing with all other parameters constant, increasing the ball radius also increases the friction torque. |

||||||

Friction Effects |

NA |

Select one of the following options:

|

||||||

Analysis Modes |

NA |

Select one of the following options:

|

||||||

Use Reaction Force |

NA |

Select this option to force the bushing model to use the bushing force vector as the normal force when computing the friction torque. Note that, due to preload, the resulting friction torque is never less than the friction torque. |