if Istf = 0 if Istf = 0

While,

Ks is an equivalent nodal stiffness of the slave component computed as:

when node is connected to a shell element. when node is connected to a shell element.

Where,

E is the Young modulus,

B is the bulk modulus of the slave component,

t is the shell thickness,

V is the solid element volume.

| 2. | If Gapmin is not specified or set to zero, a default value is computed as the minimum of t (average thickness of the slave shell elements). |

| 3. | If Igap = 1, variable gap is computed as: |

While,

gs: slave node gap:

with t is the largest thickness of the shell elements connected to the slave node. with t is the largest thickness of the shell elements connected to the slave node.

If the slave node is connected to multiple shells, the largest computed slave gap is used.

The variable gap is always at least equal to Gapmin.

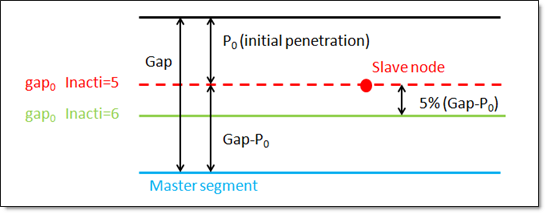

| 4. | Inacti = 6 is recommended, in order to avoid numerical (high frequency) effects into the interface before inflation. |

If Inacti = 5 or 6 and if Fpenmax is not equal to zero, nodes stiffness is deactivated if:

| 5. | The sorting factor, Bumult is used to speed up the sorting algorithm. |

| 6. | The sorting factor Bumult is machine dependent. |

| 7. | One node can belong to the two surfaces at the same time. |

| 8. | For Friction Formulation |

| ➢ | If the friction flag Ifric = 0 (default), the old static friction formulation is used: |

with with  ( ( is Coulomb Friction coefficient) is Coulomb Friction coefficient)

| ➢ | For flag Ifric > 0, new friction models are introduced. In this case, the friction coefficient is set by a function |

Where,

p is the pressure of the normal force on the master segment,

V is the tangential velocity of the slave node.

| 9. | Currently, the coefficients C1 ~ C6 are used to define a variable friction coefficient  for new friction formulations. for new friction formulations. |

The following formulations are available:

| • | Ifric = 1 (generalized viscous friction law): |

| • | Ifric = 2 (Darmstad law): |

if if

if if

if if

Where,

| • | First critical velocity  must be different to 0 ( must be different to 0 ( ). ). |

| • | First critical velocity  must be lower than the second critical velocity must be lower than the second critical velocity  ( ( ). ). |

| • | The static friction coefficient  and the dynamic friction coefficient and the dynamic friction coefficient  , must be lower than the maximum friction , must be lower than the maximum friction  ( ( and and  ). ). |

| • | The minimum friction coefficient  |

If Ifiltr ≠ 0 , the tangential forces are smoothed using a filter:

Where  coefficient is calculated from: coefficient is calculated from:

| • | If Ifiltr = 1   , simple numerical filter , simple numerical filter |

| • | If Ifiltr = 2   , standard -3dB filter, with , standard -3dB filter, with  , and T = filtering period , and T = filtering period |

| • | if Ifiltr = 3   , standard -3dB filter, with Xfreq is cutting frequency , standard -3dB filter, with Xfreq is cutting frequency |

The filtering coefficient Xfreq should have a value between 0 and 1

| 11. | The type of friction penalty formulation is based on the incremental stiffness formulation: |

The friction forces are:

While an adhesion force is computed as follows:

with with

Where,

Vt is contact tangential velocity.

|