MATX25 |

|

|

|

|

|

MATX25 |

|

|

|

|

Bulk Data Entry

MATX25 – Material Property Extension for Tsai-Wu and CRASURVT Materials for Geometric Nonlinear Analysis

Description

Defines an elasto-plastic orthotropic material with Tsai-Wu and CRASURVT yield criteria for composite shell materials.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

MATX25 |

MID |

EPSF1 |

EPSF2 |

EPST1 |

EPSM1 |

EPST2 |

EPSM2 |

DTENDS |

|

|

WPMAX |

WPREF |

IOFF |

GAMINI |

GAMMAX |

DMAX |

RATIO |

|

|

|

FSMOOTH |

FCUT |

IFORM |

|

|

|

|

|

|

Continuation line for IFORM = TSAI

|

B |

N |

FMAX |

|

|

|

|

|

|

|

SY1T |

SY2T |

SY1C |

SY2C |

ALFA |

|

|

|

|

|

SY12C |

SY12T |

C12 |

EPSR0 |

ICC |

|

|

|

|

Continuation line for IFORM = CRAS

|

C |

EPSR0 |

ALFA |

ICCG |

|

|

|

|

|

|

SY1T |

B1T |

N1T |

SMAX1T |

C1T |

|

|

|

|

|

EPS1T1 |

EPS2T1 |

SRST1 |

WMPT1 |

|

|

|

|

|

|

SY2T |

B2T |

N2T |

SMAX2T |

C2T |

|

|

|

|

|

EPS1T2 |

EPS2T2 |

SRST2 |

WMPT2 |

|

|

|

|

|

|

SY1C |

B1C |

N1C |

SMAX1C |

C1C |

|

|

|

|

|

EPS1C1 |

EPS2C1 |

SRSC1 |

WMPC1 |

|

|

|

|

|

|

SY2C |

B2C |

N2C |

SMAX2C |

C2C |

|

|

|

|

|

EPS1C2 |

EPS2C2 |

SRSC2 |

WMPC2 |

|

|

|

|

|

|

SY12T |

B12T |

N12T |

SMAX12T |

C12T |

|

|

|

|

|

EPS1T12 |

EPS2T12 |

SRST12 |

WMPT12 |

|

|

|

|

|

|

Field |

Contents |

MID |

Material ID of the associated MAT8. See comment 1. No default (Integer > 0) |

EPSF1 |

Total tensile failure in direction 1. Default = 1E30 (Real) |

EPSF2 |

Total tensile failure in direction 2. Default = 1E30 (Real) |

EPST1 |

Tensile failure strain in direction 1. (Real) |

EPSM1 |

Maximum strain in direction 1. (Real) |

EPST2 |

Tensile failure strain in direction 2. (Real) |

EPSM2 |

Maximum strain in direction 2. (Real) |

DTENDS |

Maximum damage of composite tensile strength. Default = 0.999 (Real < 1.0) |

WPMAX |

Maximum plastic work. Default = 1E30 (Real) |

WPREF |

Reference plastic work. Default = 1.0 (Real) |

IOFF |

Total element failure criteria. Default = 0 (Integer) = 0: shell is deleted if Wp* > Wp*max for 1 layer |

GAMINI |

Delamination shear strain. See comment 11. Default = 1E30 (Real) |

GAMMAX |

Maximum shear strain. Default = 1.1E30 (Real) |

DMAX |

Maximum damage. Default = 1.0 (Real) |

RATIO |

Ratio parameter control to delete shell elements Default = 1.0 (Real) < 0.0: the element will be deleted if all of the layers but one fail (the number of layers that did not fail is equal to 1). > 0.0: the element will be deleted if:

|

FSMOOTH |

Strain rate smoothing flag. Default = OFF (ON or OFF) |

FCUT |

Cutoff frequency for strain rate filtering. Default = 1E30 (Real) |

IFORM |

Formulation flag. Default = TSAI (TSAI or CRAS) |

IFORM = TSAI |

|

B |

Hardening parameter. (Real) |

N |

Hardening exponent. Default = 1.0 (Real) |

FMAX |

Maximum value of yield function. Default = 1E30 (Real) |

SY1T |

Tension in direction 1. (Real > 0) |

SY2T |

Tension in direction 2. (Real > 0) |

SY1C |

Compression yield stress in direction 1. (Real > 0) |

SY2C |

Compression yield stress in direction 2. (Real > 0) |

ALFA |

F12 reduction factor. Default = 1.0 (Real) |

SY12C |

Compression yield stress in direction 12. (Real > 0) |

SY12T |

Tension yield stress in direction 12. (Real > 0) |

C12 |

Strain rate coefficient. (Real) = 0.0: no strain rate dependency. |

EPSR0 |

Reference strain rate. (Real) |

ICC |

Flag for yield stress in shear and strain rate. See comment 9. (Integer) = 0: Default set to 1 |

IFORM = CRAS |

|

C |

Global strain rate coefficient for plastic work criteria. (Real) |

EPSR0 |

Reference strain rate. (Real) |

ALFA |

F12 reduction factor. Default= 1.0 (Real) |

ICCG |

Global composite plasticity parameters flag for strain rate computation: (See comment 9). = 1: Strain rate effect on SMAX1T, SMAX2T, SMAX1C, SMAX2C, SMAX12T; no strain rate effect on WPMAX. = 2: No strain rate effect on SMAX1T, SMAX2T, SMAX1C, SMAX2C, SMAX12T; no strain rate effect on WPMAX. = 3: Strain rate effect on SMAX1T, SMAX2T, SMAX1C, SMAX2C, SMAX12T and strain rate effect on WPMAX. = 4: No strain rate effect on SMAX1T, SMAX2T, SMAX1C, SMAX2C, SMAX12T and strain rate effect on WPMAX. Default = 1 (Integer) |

SY1T |

Tension yield stress in direction 1. (Real > 0) |

B1T |

Hardening parameter in direction 1. (Real) |

N1T |

Hardening exponent in direction 1. Default = 1.0 (Real) |

SMAX1T |

Maximum stress in direction 1. Default = 1E30 (Real) |

C1T |

Strain rate coefficient in direction 1. 0: no strain rate dependency. Default = C (Real) |

EPS1T1 |

Initial softening strain in direction 1. Default = 1E30 (Real) |

EPS2T1 |

Maximum softening strain in direction 1. Default = 1.2 * EPS1T1 (Real) |

SRST1 |

Residual stress in direction 1. Default = 10E-3*SY1T (Real) |

WMPT1 |

Maximum plastic work in tension direction 1. Default = 1E30 (Real) |

SY2T |

Tension yield stress in direction 2. (Real > 0) |

B2T |

Hardening parameter in direction 2. Default = B1T (Real) |

N2T |

Hardening exponent in direction 2. Default = N1T (Real) |

SMAX2T |

Maximum stress in direction 2. Default = 1E30 (Real) |

C2T |

Strain rate coefficient in direction 2. 0: no strain rate dependency Default = C (Real) |

EPS1T2 |

Initial softening strain in direction 2. Default = 1E30 (Real) |

EPS2T2 |

Maximum softening strain in direction 2. Default = 1.2*EPS1T1 (Real) |

SRST2 |

Residual stress in direction 2. Default = 10E-3 * SY2T (Real) |

WMPT2 |

Maximum plastic work in tension direction 2. Default = 1E30 (Real) |

SY1C |

Compression yield stress in direction 1. (Real > 0) |

B1C |

Hardening parameter in direction 1. Default = B2T (Real) |

N1C |

Hardening exponent in direction 1. Default = N2T (Real) |

SMAX1C |

Maximum stress in direction 1. Default = 1E30 (Real) |

C1C |

Strain rate coefficient in direction 1. = 0.0: no strain rate dependency. Default = C (Real) |

EPS1C1 |

Initial softening strain in direction 1. Default = 1E30 (Real) |

ESP2C1 |

Maximum softening strain in direction 1. Default = 1.2*EPS1C1 (Real) |

SRSC1 |

Residual stress in direction 1. Default = 10E-3*S1YC (Real) |

WMPC1 |

Maximum plastic work in compression direction 1. Default = 1E30 (Real) |

SY2C |

Compression yield stress in direction 2. (Real > 0) |

B2C |

Hardening parameter in direction 2. Default = B1C (Real) |

N2C |

Hardening exponent in direction 2 Default = N1C (Real) |

SMAX2C |

Maximum stress in direction 2. Default = 1E30 (Real) |

C2C |

Strain rate coefficient in direction 2. = 0.0: no strain rate dependency. Default = C (Real) |

EPS1C2 |

Initial softening strain in direction 2. Default = 1E30 (Real) |

EPS2C2 |

Maximum softening strain in direction 2. Default = 1.2*EPS1C2 (Real) |

SRSC2 |

Residual stress in direction 2. Default = 10E-3*S2YC (Real) |

WMPC2 |

Maximum plastic work in compression direction 2. Default = 1E30 (Real) |

SY12T |

Tension yield stress in direction 12. (Real > 0) |

B12T |

Hardening parameter in direction 12. Default = B2C (Real) |

N12T |

Hardening exponent in direction 12. Default = 1.0 (Real) |

SMAX12T |

Maximum stress in direction 12. Default = 1E30 (Real) |

C12T |

Strain rate coefficient in direction 12. = 0.0: no strain rate dependency. Default = C (Real) |

EPS1T12 |

Initial softening strain in direction 12. Default = 1E30 (Real) |

EPS2T12 |

Maximum softening strain in direction 12. Default = 1.2*EPS1T12 (Real) |

SRST12 |

Residual stress in direction 12. Default = 10E-3*SY12T (Real) |

WMPT12 |

Maximum plastic work in shear. Default = 1E30 (Real) |

| 1. | The material identification number must be that of an existing MAT8 bulk data entry. Only one MATXi material extension can be associated with a particular MAT8. |

| 2. | MATX25 is only applied in geometric nonlinear analysis subcases which are defined by ANALYSIS = EXPDYN. It is ignored for all other subcases. |

| 3. | Tsai-Wu formula (IFORM=TSAI) is not available with QEPH (ISHELL=24 on PCOMPX) shell elements, it is only available with Q4 (ISHELL=1, 2, 3, 4 on PCOMPX) and QBAT(ISHELL=12 on PCOMPX) shell elements. |

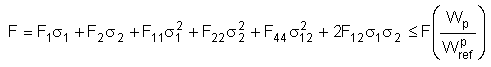

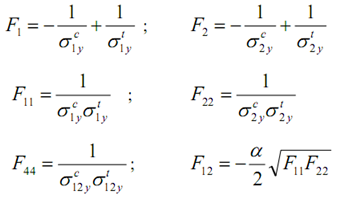

| 4. | The Lamina yield surface for Tsai-Wu criteria (IFORM=TSAI) is: |

Where,

Wp is the plastic work

![]() is the reference plastic work

is the reference plastic work

is the yield envelope evolution:

is the yield envelope evolution:

Where,

b is the hardening parameter for plastic work

n is the hardening exponent

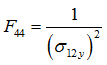

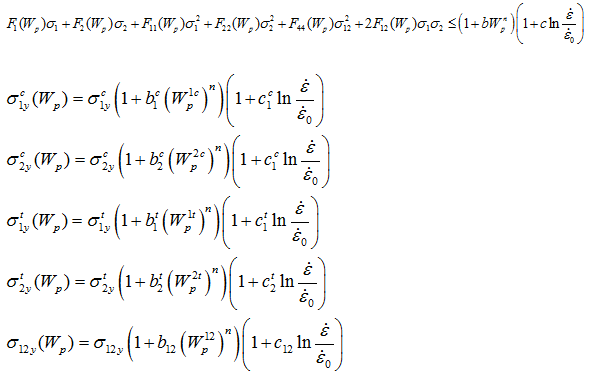

| 5. | The CRASURV model is an improved version of the former law based on the standard Tsai-Wu criteria. The main changes concern the expression of the yield surface before plastification and during work hardening. First, in a CRASURV model, the coefficient F44 depends only on one input parameter: |

Another modification concerns the parameters Fij which are expressed now in function of plastic work and plastic work rate, as shown below:

| 6. | If the total tensile failure value EPSF1 is reached in the direction 1 and respectively ε EPSF2 in the direction 2, the stresses tensor in the layer is permanently reset to 0. |

| 7. | If a shell has several layers with one material per layer (different materials, different IOFF), the IOFF used is the one that is associated to the shell in the shell element definition. |

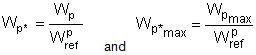

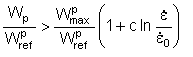

| 8. | Both Wp* and Wp*max are defined as follows: |

| 9. | The plastic work criteria is: |

When ICC=2, 3, or 4 for Tsai-Wu formula, when ICCG=3 or 4 for CRASURV formula.

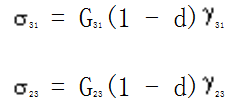

| 10. | Delamination is a global model: |

with ![]() applies to the all shell and not independently per each layer.

applies to the all shell and not independently per each layer.

| 11. | Thereby, the coefficients GAMINI, GAMMAX, and DMAX considered, are the coefficients which are defined in the global material associated to the shell equivalent out-of-plane shear strain. |

| 12. | The IOFF and RATIO field values are utilized only if they are defined in the material assigned to a part, these fields are not considered if they are only defined in material used for a layer in the property entry. This option is not available for solid elements. |

| 13. | This card is represented as extension to a MAT8 material in HyperMesh. |

See Also: