MATX70 |

|

|

|

|

|

MATX70 |

|

|

|

|

Bulk Data Entry

MATX70 – Material Property Extension for Tabulated Visco-elastic Foam Material for Geometric Nonlinear Analysis

Description

Defines additional material properties for tabulated visco-elastic foam material for geometric nonlinear analysis.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

MATX70 |

MID |

EMAX |

EPSMAX |

FSMOOTH |

FCUT |

NLOAD |

NULOAD |

IFLAG |

|

|

SHAPE |

HYS |

|

|

|

|

|

|

|

If NLOAD > 1, NLOAD times

|

TIDL |

EPSRL |

FSCALL |

|

|

|

|

|

|

If NULOAD > 0, NULOAD times

|

TIDU |

EPSRU |

FSCALU |

|

|

|

|

|

|

|

Field |

Contents |

MID |

Material ID of the associated MAT1. See comment 1. No default (Integer > 0) |

EMAX |

Maximum young modulus. If blank, EMAX is set and equal to Young modulus on MAT1 card. (Real > 0) |

EPSMAX |

Maximum plastic (failure) strain. If blank, it will be calculated automatically, if EMAX is less than the maximum tangent according to the input stress-strain curves. (Real > 0) |

FSMOOTH |

Strain rate smoothing flag. Default = OFF (ON or OFF) |

FCUT |

Cutoff frequency for strain rate filtering. Default = 1.E30 (Real > 0) |

NLOAD |

Number of loading stress-strain function. Default = 1 (Integer > 1) |

NULOAD |

Number of unloading stress-strain function. Default = 1, if IFLAG = 0 (Integer > 0) |

IFLAG |

Flag to control the loading/unloading behavior. See comment 5. Default = 0 (Integer) = 0: Behavior follows the loading and unloading curves, respectively. = 1: Behavior follows the loading/unloading curves. For unloading, the deviatoric stress is modified. = 2: Behavior follows the loading/unloading curves. For unloading, the stress tensor is modified. = 3: The loading curve is used for both loading and unloading. For unloading, the deviatoric stress is modified. The unloading curves are ignored. = 4: The loading curve is used for both loading and unloading. For unloading, the stress tensor is modified. The unloading curves are ignored. |

SHAPE |

Shape factor. Default = 1.0 (Real) |

HYS |

Hysteresis unloading factor. Default = 1.0 (Real) |

TIDL |

Identification number of TABLES1 entry that defines the loading function. (Integer > 0) |

EPSRL |

Strain rate for loading function. Default = 0.0 (Real) |

FSCALL |

Scale factor for loading function. Default = 1.0 (Real) |

TIDU |

Identification number of TABLES1 entry that defines the unloading function. No default (Integer > 0) |

EPSRU |

Strain rate for unloading function. Default = 0.0 (Real) |

FSCALU |

Scale factor for unloading function. Default = 1.0 (Real) |

| 1. | The material identification number must be that of an existing MAT1 bulk data entry. Only one MATXi material extension can be associated with a particular MAT1. |

| 2. | MATX70 is only applied in geometric nonlinear analysis subcases which are defined by ANALYSIS = EXPDYN. It is ignored for all other subcases. |

| 3. | This material law can be used only with solid elements. The corresponding PSOLIDX property must define ISOLID = 1 (Belytschko element), ISMSTR = 1 (small strain), and IFRAME = OFF (not co-rotational). |

| 4. | The loading and unloading functions use engineering stress-strain curve. |

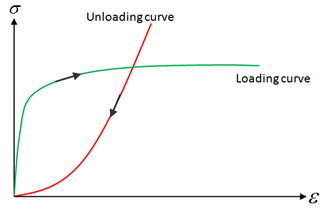

Loading and unloading stress-strain curves

| 5. | The loading and unloading behavior is determined by IFLAG. |

| • | IFLAG = 0: The material behavior follows the defined curves for loading and unloading. NLOAD and NULOAD must be greater than 0. |

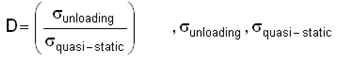

| • | IFLAG = 1: Both loading curves are used respectively. For unloading, the deviatoric stress is modified by using the quasi-static unloading curve. |

σ = (1 - D)(σ + p*I) – p*I

where, D is calculated from the quasi-static unloading curve,

are the current stresses computed respectively from the unloading and quasi-static curves.

The pressure is:

p = -(σxx + σyy + σzz) / 3

| • | IFLAG = 2: Both loading and unloading curves are used respectively. For unloading, the stress tensor is modified using the quasi-static unloading curve σ = (1 - D)σ, where D is calculated from the quasi-static unloading curve,  |

are the current stresses computed respectively from the unloading and quasi-static curves.

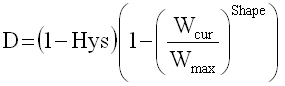

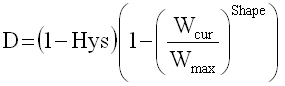

| • | IFLAG = 3: The loading curves are used for both loading and unloading behavior. The unloading curve is ignored. The deviatoric unloading stress is modified using: |

σ = (1 - D)(σ + p*I) – p*I

where, Wcur and Wmax are the current and maximum energy, respectively.

| • | IFLAG = 4: The loading curves are used for both loading and unloading behavior. The unloading curve is ignored. The unloading stress tensor is modified using σ = (1 - D)σ. |

where, Wcur and Wmax are the current and maximum energy, respectively.

| • | For IFLAG = 3 or 4: The unloading curves are not used. |

| 6. | For stresses above the last load function, the behavior is extrapolated by using the two last load functions. In order to avoid huge stress values, it is recommended to repeat the last load function. |

| 7. | When maximum plastic strain EPSMAX is reached, EMAX is used whatever the curve definition is. |

| 8. | Young's modulus E on MAT1 card would be modified automatically if it is less than the initial value according to the input stress-strain curves' tangents. |

| 9. | This card is represented as a material in HyperMesh. |

See Also: