PCOMPP |

|

|

|

|

|

PCOMPP |

|

|

|

|

PCOMPP – Composite Laminate Property for Ply-Based Composite Definition

Defines the properties of a composite laminate material used in ply-based composite definition.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

PCOMPP |

PID |

Z0 |

NSM |

SB |

FT |

TREF |

GE |

|

|

|

Field |

Contents |

PID |

Unique composite property identification number. No default (Integer > 0) |

Z0 |

Real number or character input (Top/Bottom) Real Number - It represents the distance from the shell element reference plane to the bottom surface of the shell (Default = -0.5 * Thick, Thick being the composite total thickness (Real or blank)). Character Input - See comment 12. |

NSM |

Nonstructural mass per unit area. No default (Real) |

SB |

Allowable inter-laminar shear stress (shear stress in the bonding material). Disregarded if blank or 0.0. No default (Real > 0.0) |

FT |

Failure theory code. If blank, no failure calculations are performed. The following failure theory codes are supported: HILL for Hill theory HOFF for Hoffman theory TSAI for Tsai-Wu theory STRN for Maximum Strain theory HASH for Hashin criteria PUCK for Puck failure criteria See comments 10 and 13. Default = no failure calculations are performed (HILL, HOFF, TSAI, STRN, HASH or PUCK). |

TREF |

Reference (stress free) temperature. See comment 2. Default = 0.0 (Real) |

GE |

Damping coefficient. See comments 6 and 7. Default = 0.0 (Real) |

Comments

| 1. | The PCOMPP card is used in combination with the STACK and PLY cards to create composite properties through the ply-based definition. |

| 2. | TREF specified on the PCOMPP entry overrides reference temperatures given for individual ply materials. If TREF is not specified (blank) on the PCOMPP card, then all the ply materials must have the same reference temperature. |

| 3. | For composites with offset (Z0 ≠ 0.5 * Thickness), correct values of shell stresses for the bottom and top surfaces of the shell are produced. |

|

| 4. | For composites with offset (Z0 ≠ 0.5 * Thickness), the buckling results will not be correct. This is because the membrane-bending coupling resulting from composite offset is not included in the differential stiffness matrix. Therefore, the preferred method of incorporating offset in buckling analysis is the element offset ZOFFS. |

| 5. | Element GRID thicknesses cannot be defined for elements that reference PCOMPP data. |

| 6. | GE given on the PCOMPP entry will be used for the element, and the values supplied on material entries for individual plies are ignored. You are responsible for supplying the equivalent damping value on the PCOMPP entry. |

| 7. | To obtain the damping coefficient GE, multiply the critical damping ratio C/C0 by 2.0. |

| 8. | Note that Hill’s failure theory does not differentiate between compressive and tensile strength. While different values of respective strength limits are accepted, it is still recommended that Xt is set to be equal to Xc, and Yt is set to be equal to Yc when this criteria is used. Xt and Xc are allowable tensile and compressive stresses in the principle x direction of the material. Yt and Yc are allowable tensile and compressive stresses in the principle y direction of the material. |

| 9. | Failure index calculation according to Maximum Strain Theory is based on mechanical component of strain only, not on total strain. This is because only the mechanical strain contributes to actual damage of the respective ply (pure thermal expansion produces no damaging effects). |

| 10. | According to the formula, some failure criteria (for example, Tsai-Wu and Hoffman) would produce a negative ply failure, depending on the problem. |

| 11. | If ‘PARAM, SRCOMPS, YES’ is added to the input file, strength ratios with respect to designated failure theory are output for composite elements that have failure indices requested. |

| 12. | The following two formats are permissible for the Z0 field: |

Real Number:

It represents the distance from the shell element reference plane to the bottom surface of the shell (Default = -0.5 * Thick, Thick being the composite total thickness (Real or blank)).

Surface:

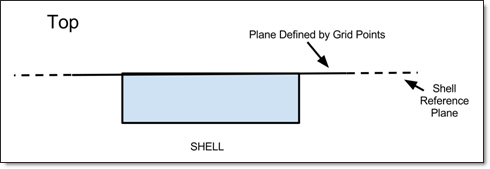

Top:

The shell reference plane, the plane defined by the grid points, and the top surface of the shell are coplanar.

This makes the effective "Real" Z0 value equal to the composite total thickness (-1.0 * Thick). See Figure 1.

Figure 1: Top option for Z0

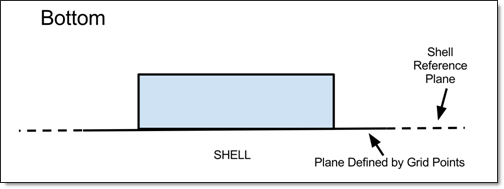

Bottom:

The shell reference plane, the plane defined by the grid points, and the bottom surface of the shell are coplanar.

This makes the effective "Real" Z0 value equal to 0. See Figure 2.

Figure 2: Bottom option for Z0

Automatic offset control is available in composite free-size and sizing optimization where the specified offset values are automatically updated based on thickness changes.

| 13. | The material parameters, Xt, Xc, Yt, Yc, and S on the MAT8 Bulk Data Entry should be specified for failure criteria calculation. |

| 14. | This card is represented as a property in HyperMesh. |

See Also: