STACK |

|

|

|

|

|

STACK |

|

|

|

|

STACK – Stacking Information for Ply-Based Composite Definition

Defines the stacking information and stacking sequence for ply-based composite definition.

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

STACK |

ID |

LAM |

PLYID1 |

PLYID2 |

PLYID3 |

PLYID4 |

PLYID5 |

PLYID6 |

|

|

PLYID7 |

… |

|

|

|

|

|

|

|

Optional continuation lines for substack definitions:

|

SUB |

SID1 |

SNAME1 |

SPLYID11 |

SPLYID12 |

SPLYID13 |

SPLYID14 |

SPLYID15 |

|

|

|

SPLYID16 |

SPLYID17 |

... |

... |

... |

... |

... |

|

|

|

... |

... |

|

|

|

|

|

|

Optional continuation lines for interface definitions:

|

INT |

IPLYID11 |

IPLYID12 |

|

|

|

|

|

|

Defines a stack consisting of 8 plies with the SMEAR option

|

Defines a stack with substack and interface information. They ply layout is shown below.

|

Field |

Contents |

|

ID |

Unique stack identification number. No default (Integer > 0) |

|

LAM |

Laminate option. If blank, all plies must be specified and all stiffness terms are developed. The following options are supported: |

|

SYM: |

Only plies on the bottom half of the composite lay-up need to be specified. These plies are automatically symmetrically reflected to the top half of the composite and given consecutive numbers from bottom to top. |

|

MEM: |

All plies must be specified, but only membrane terms are developed. |

|

BEND: |

All plies must be specified, but only bending terms are developed. |

|

SMEAR: |

All plies must be specified, stacking sequence is ignored, and MID1 is set equal to MID2 on the derived equivalent PSHELL, while MID3, MID4, TS/T, and 12I/T**3 are set to blank. |

|

SMEARZ0: |

All plies must be specified, stacking sequence is ignored. While the laminate is still considered to be made of homogenized (smeared) material, the effect of offset Z0 is taken into account. Hence, if Z0 ≠ -0.5 * Thick, the equivalent PSHELL will include MID1, MID2 and MID4. MID3 is still set to blank, that is no transverse shear deformation is considered. |

|

SMCORE: |

All plies must be specified. The last ply specifies core properties and the previous plies specify face sheet properties. The face sheet properties are calculated without regard for stacking sequence; half of the total face sheet thickness is then placed on top of the core, and half is placed on the bottom, to produce a symmetric laminate. Stiffness of the core is ignored while its density is included in inertia calculations. |

|

SYMEM: |

Only plies on the bottom half of the composite lay-up need to be specified. These plies are automatically symmetrically reflected to the top half of the composite and given consecutive numbers from bottom to top. Only membrane terms are developed for the full laminate. |

|

SYBEND: |

Only plies on the bottom half of the composite lay-up need to be specified. These plies are automatically symmetrically reflected to the top half of the composite and given consecutive numbers from bottom to top. Only bending terms are developed for the full laminate. |

|

SYSMEAR: |

Only plies on the bottom half of the composite lay-up need to be specified. These plies are automatically symmetrically reflected to the top half of the composite and given consecutive numbers from bottom to top. Stacking sequence is ignored, and MID1 is set equal to MID2 on the derived equivalent PSHELL, while MID3, MID4, TS/T and 12I/T**3 are set to blank. |

|

Default = blank, that is all plies must be specified (SYM, MEM, BEND, SMEAR, SMCORE, SYMEM, SYBEND or SYSMEAR) |

||

PLYID# |

PLY identification number. No default (Integer > 0) |

|

SUB |

Indicates that substack data is to follow. |

|

SID# |

Substack identification number. No default (Integer > 0) |

|

SNAME# |

Substack user-defined name. No default (Character) |

|

SPLYID# |

PLY identification number. No default (Integer > 0) |

|

INT |

Indicates that interface data is to follow. |

|

IPLYID# |

PLY identification number. No default (Integer > 0) |

|

Comments

| 1. | The STACK card is used in combination with the PCOMPP and PLY cards to create composite properties through the ply-based definition. |

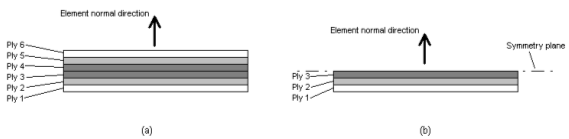

| 2. | Plies are listed from the bottom surface upward, in respect to the element’s normal direction. In the image below, (a) shows the stacking sequence for a non-symmetrical laminate, and (b) shows the stacking sequence for a symmetrical laminate. |

| 3. | For convenience, element output for the SMEAR and SMCORE options includes both homogenized shell stresses and individual ply stresses. However, because stacking sequence is ignored in these options, individual ply stresses will only be valid in cases of pure membrane deformation. |

| 4. | Multiple instances of substack and interface continuations are allowed. |

| 5. | This card is represented as a laminate in HyperMesh. |

See Also: