PWELD |

|

|

|

|

|

PWELD |

|

|

|

|

Bulk Data Entry

PWELD – WELD Element Property

Description

Defines properties of connector (CWELD) elements.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

PWELD |

PID |

MID |

D |

|

|

MSET |

|

TYPE |

|

|

DTAB |

TID |

|

|

|

|

|

|

|

|

Field |

Contents |

PID |

Property identification number. No default (Integer > 0) |

MID |

Material identification number. See comment 1. No default (Integer > 0) |

D |

Diameter of the connector. See comment 1. No default (Real > 0.0) |

MSET |

Flag to eliminate m-set degrees-of-freedom. = ON: generates explicit m-set constraints. = OFF (default): incorporates constraints at the element stiffness matrix level avoiding explicit m-set constraint equations. The exact same results will be obtained regardless of this choice. Default = OFF (ON or OFF) |

TYPE |

Connection type. See comment 2. SPOT: indicates spot weld connector. Set to activate Spot Weld Fatigue Analysis. blank: indicates general connector. Default = blank (SPOT or blank) |

DTAB |

The weld element diameter is determined from the table TID. |

TID |

Identification number of a TABLEDi entry that defines the weld element diameter as a function of the minimum shell thickness of the corresponding shell elements (sheets). See comment 3 No default (Integer > 0) |

Comments

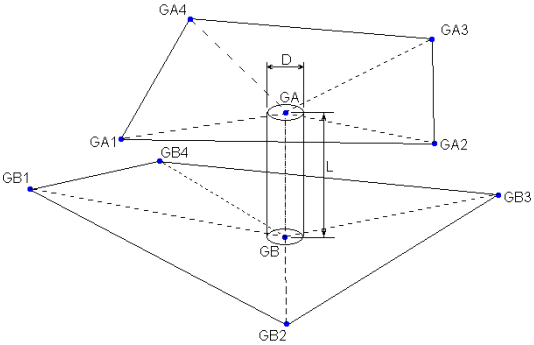

| 1. | Material MID, diameter D, and the length are used to calculate the stiffness of the connector in 6 directions. MID can only refer to the MAT1 bulk data entry. The length is the distance of GA to GB (see below). |

Length and Diameter of Weld connector

| 2. | If TYPE=SPOT and if the formats PARTPAT, ELPAT, or ELEMID on the CWELD entry are used, then the effective length for the stiffness of the CWELD element is set to |

| 3. | The TID field references a TABLEDi entry that defines the weld diameter as a function of minimum attached shell thicknesses. |

| • | TID consists of list of minimum thickness values (X) vs corresponding weld diameters (Y). |

| • | From the table TID lookup you get Y (weld diameter) for the min thickness (used for the lookup). |

| 4. | This card is represented as a property in HyperMesh. |

See Also: