Shell Elements (/PROP/SHELL) |

|

|

|

|

|

Shell Elements (/PROP/SHELL) |

|

|

|

|

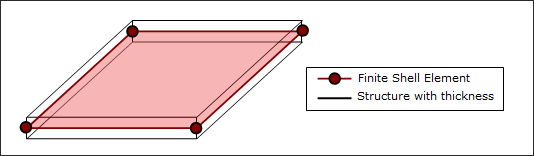

A shell is defined by a curved mid-surface and a thickness h, which is supposed to be very small compared to the two other dimensions. A shell element is the most common element; a full car crash model is made of at least 90% shell elements. They include membrane, bending and shear deformation and the normal stress, through the thickness, is always zero.

Fig. 2.5: Shell element

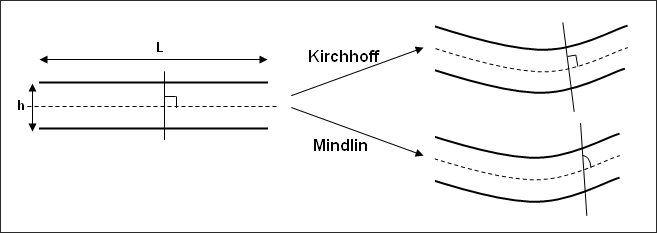

In RADIOSS, the standard shell elements are Mindlin plate elements with transverse shear deformation. These elements are more accurate than the standard Kirchhoff element; which does not take into account deformation; due to transverse shear, a plane orthogonal to the mid-plane remains orthogonal during the deformation.

Fig. 2.6: Shell Models

Even if the Kirchhoff model is less accurate, if the ratio L/h is greater than 20, the statements made by Kirchhoff are correct; but if the ratio L/h is between 10 and 20, the assumption stating that a plane orthogonal to the mid-plane remains orthogonal during the deformation is no longer valid, and the Mindlin plate model must be considered in which transverse shear strain is taken into account. In RADIOSS, under-integrated shell elements (both 4-node and 3-node shell) are based on Mindlin assumptions. There is no specific formulation that enables to offset the mid-plane of the element away from the nodes; therefore, it is very important to discretize structures with thin walls on the mid-surface.

Shell element formulation plays a considerable role in crash worthiness simulations. RADIOSS shell elements are mainly based on Mindlin-Reissner shell theory. The formulation is then valid for moderately thick shells and for thin shells. The under-integrated elements are the most popular because of their low cost.

Mesh |

Element Name |

Number of Integration Points |

Hourglass Formulation |

Comments |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

BT (Classic Q4) |

1 |

Four types based on penalty method |

|

||||||

|

QEPH |

1 |

Physical stabilization |

|

||||||

|

QBAT |

2x2 |

Fully-integrated element |

|

||||||

|

C0 |

1 |

--- |

|

||||||

|

DKT18 |

3 |

--- |

|

||||||

|

S3N6 |

1 |

--- |

|

Table 2.3 Shell element library

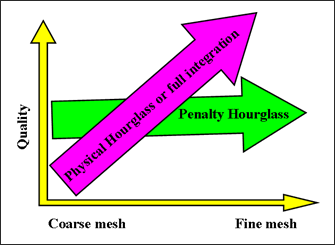

The choice of a shell element for a given application needs experiences. The following general guidelines may be helpful:

| • | The BT element is simple, efficient and has a low cost. As it is under-integrated, the element is not very sensitive to the mesh quality and can be used for the case of coarse mesh. |

| • | For cases of quasi-static analysis, fine mesh, warped surface and buckling, it is advisable to use QEPH or QBAT elements. |

| • | QBAT is the most accurate element in RADIOSS. However, as it is fully-integrated, it costs two to three times more than a BT element. |

| • | QEPH is the best compromise between cost and quality. Generally, it costs no more than 15% of a BT element and the results obtained by this element are close to those of QBAT. |

| • | Triangles are not recommended. A C0 element is too stiff and DKT18 comes with a high cost. The number of total triangles in a mesh is generally limited to 5% to ensure a good quality. |

| • | The S3N6 element has as good a behavior in bending as DKT18. It can also be used for some special applications, such as stamping simulations. |

The relation between quality of results and mesh is schematically presented in Fig. 2.7.

Fig. 2.7: Use of shell formulations for different meshes

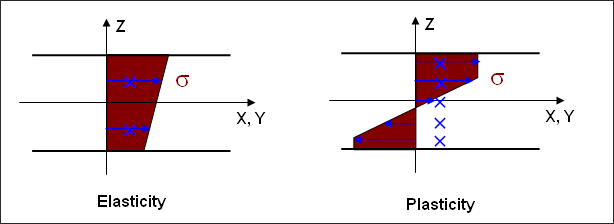

In an elastic shell, the normal stress variation through the thickness is linear; therefore the internal energy can be obtained by analytical integration. In case of plasticity, the stress distribution becomes nonlinear and a minimum of three integration points are required to take the nonlinearity into account. The nonlinear distribution of stress can be approached by measuring values at some added integration points. The quality of internal energy estimation depends on the number of integration points and the cost. A good compromise between cost and quality can be found, taking into account, material nonlinearity, thickness and bending rate. The number of integration points can be increased up to 10 in RADIOSS V5x. Using five integration points will provide better results; especially if the thickness is greater than 2mm, but the increase in CPU time is not negligible. To emulate a membrane element with no bending or transverse shear, it is enough to use only one integration point. For an elastic material (Law 1) due to the analytical computation, the option is ignored.

Comment

| 1. | One way to get a membrane element with an elastic material is to use an elasto-plastic law (Johnson-Cook law) with a very high yield stress (for example: 1e+30). |

Fig. 2.8: Normal stress distribution in a section a shell

One way to get fairly accurate results with a low CPU cost is to use the global integration. It consists in the transformation of von Mises plasticity criteria, in a so-called Iluyshin criteria, where the stress components at integration points are replaced by internal forces (N, M, T, etc.).

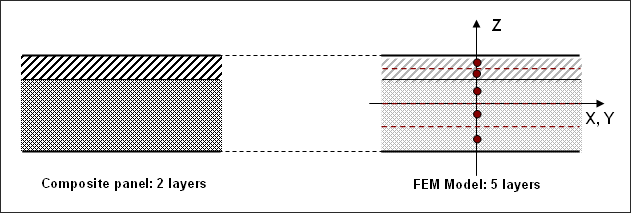

For multi-layered shell element, one integration point is assigned at the center of each layer. Note that for a composite made of only two layers, it is necessary to add extra layers (with respect of the overall thickness) in order to get a proper number of integration points.

Fig. 2.9: Layers definition for composite to set the number of integration points

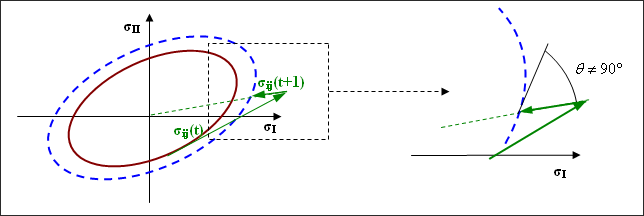

In plasticity computation, two fundamental assumptions must be satisfied. First, the stress in the plastic region must verify the plasticity criteria (for example, von Mises criteria). Second, in the principal stresses space is the direction (![]() ), due to work hardening is normal to the yield surface.

), due to work hardening is normal to the yield surface.

By default a radial return is applied on the stress tensor during the projection on yield surface. This method is better, but the plasticity is approximate, and the second assumption is not always satisfied (Fig. 2.10). An iterative orthogonal projection is also available, this method enables to satisfy the second assumption using an iterative algorithm (see the RADIOSS Theory Manual). Use iterative projection if a high accuracy on stress distribution after projection is required. This is the case if residual stress tensor or spring back is required. The error in radial return is higher when the difference between principal stress components is large (pure shear case, for example).

Fig. 2.10: Radial return

By default, shell thickness is supposed constant during shell deformation. Initial thickness is used to compute strains and to integrate stresses, but the thickness variation is still computed for post-processing reasons. If a variable thickness (Ithick =1) is used, true thickness is computed not only for post-processing, but also for strain computation and stresses integration.

Comment

| 1. | For accurate results, especially when necking or spring back, it is strongly recommended to use iterative plastic projection and thickness variation. |