Seam panel |

|

|

|

|

|

Seam panel |

|

|

|

|

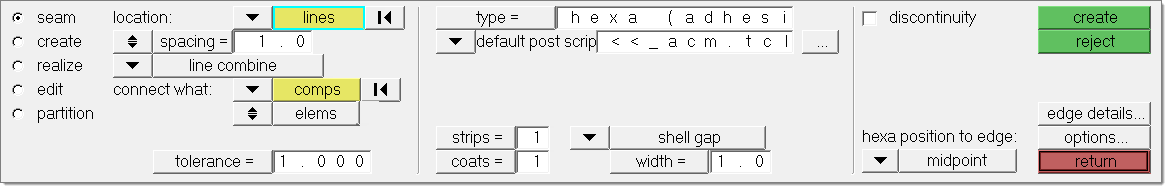

Use the connector Seam panel to create connectors that represent line connectors such as seam welds. These connectors can later be realized as standard or custom weld representations.

When the Seam panel is active, only seam-type connectors display in the graphics area; graphics for other connector types are suppressed until you exit the panel.

Each type of edit option for seams is arranged into its own subpanel. You can move freely between subpanels--your work on one subpanel will not be lost if you switch to a different subpanel, then return. However, similar settings will not be shared between subpanels, so for example changing the tolerance in one subpanel does not change it in any of the others. In most cases one or more green command buttons on the right edge of the subpanel must be used to execute the function once all options have been specified.

| • | Set the panel mode by selecting the subpanel appropriate to the type of edit you wish to perform. |

| • | In the subpanel, choose input options to characterize new seams, or edit existing ones. |

The Seam panel contains the following subpanels and command buttons:

| • | Seam: The seam connector is both created and realized in one shot. |

| • | Create: The seam connector is created only--no realization occurs on this subpanel. |

| • | Realize: An existing seam connector is realized only--no creation options exist on this subpanel. |

| • | Edit: An existing seam connector gets edited. |

| • | Partition: An existing seam connector gets partitioned--that is, seams are separated into sections of connections that passed or failed valid projections. |

Increasingly often the location of a seam is given by the welding or gluing robot path as a geometrical line. These lines are mostly continuous lines even though the robot doesn’t weld or glue on a line's entire path. As a result, connectors based on these kinds of lines contain sections where a valid projection to at least two links is not possible. The seam partition functionality has the capability to identify these sections without valid projections. For each point along the seam the availability of two valid projections onto link candidates with respect to a user-specified tolerance is identified. At each position where a point with valid projections follows on a point with invalid projections or vice versa, the connector is partitioned. The picture below shows a long, straight seam with all shell components defined as link candidates. After partitioning the seam is separated into "passed" and "failed" connector sections. In the picture the connectors are shown in their component color; in mint green (passed) and magenta (failed). The subsequent realization can easily be performed on all passed connectors.

The default projection test is a normal projection considering the tolerance, so the failures in the example above are mostly obvious--either the projections cannot be done at all, or the distance is too great. If there is only one point with valid projections in between two points without valid projections, the one is also marked as failed. This is because a seam needs to consist of at least two points. See picture below as an example.

|

The seam, create and realize subpanels use the same set of entry controls. They are organized in three different columns:

| 1. | The first column contains everything related to connector creation and link detection. |

| 2. | The second column contains everything related to realization type, post script and property assignment. |

| 3. | The third column contains everything related to the final connection to the link entities. |

These columns and their organization are illustrated in detail in Connector Panel Structure in the Connectors chapter. See Special Realization Types in the Connectors chapter for further information on specific realization types.

From the seam panel you also have direct access to the Connector Options panel, where general and connector type-specific settings can be set. In particular, settings which don’t need to be altered very often are provided there.

|

|

|

The effects of these options are illustrated in detail in the Seam Panel Realization Methods topic of the HyperMesh User's Guide.

|

|

|||||||||||||||||||||||||||||||||||||

|

|

An Alphabetical List of HyperMesh Panels