MATS1 |

|

|

|

|

|

MATS1 |

|

|

|

|

Bulk Data Entry

MATS1 – Stress-dependent and Temperature-dependent Material Definition

Description

Specifies stress-dependent and temperature-dependent material properties for use in applications involving nonlinear materials. This entry is used if a MAT1 entry is specified with the same MID in a nonlinear subcase.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

MATS1 |

MID |

TID |

TYPE |

H |

YF |

HR |

LIMIT1 |

|

|

|

TYPSTRN |

|

|

|

|

|

|

|

|

|

Field |

Contents |

MID |

Identification number of a MAT1 entry. (Integer > 0) |

TID |

Identification number of a TABLES1 or TABLEST entry. If H is given, then this field must be blank. See comment 3. (Integer > 0 or blank) |

TYPE |

Type of material nonlinearity. PLASTIC – Elastoplastic material NLELAST – Nonlinear elastic material Default = PLASTIC |

H |

Work hardening slope (slope of stress versus plastic strain) in units of stress. For elastic-perfectly plastic cases, H = 0.0. For more than a single slope in the plastic range, the stress-strain data must be supplied on a TABLES1 entry referenced by TID, and this field must be blank. See comment 2. (Real > 0) |

YF |

Yield function criterion, selected by the following value (Integer): 1 = von Mises (Default) (Integer > 0 or blank) |

HR |

Hardening Rule, selected by the following value (Integer): 1 = Isotropic Hardening (Default) 2 = Kinematic Hardening 3 = Mixed Hardening with 30% contribution of the Kinematic Hardening and 70% contribution of the Isotropic Hardening Adjustable Mixed Hardening is selected by choosing (Real) value for HR: 0 < HR < 1 indicates a mixed combination of Isotropic and Kinematic Hardening. The contribution of the Kinematic Hardening is HR whereas the contribution of the Isotropic Hardening is 1 – HR. See comment 4. (Integer 0, 1, 2, 3 or blank, or Real > 0 and < 1) |

LIMIT1 |

Initial yield point. The LIMIT1 field can be blank, if the initial yield point value is defined via a referenced TABLES1 entry on the TID field. OptiStruct will error out if LIMIT1 is blank and TID does not reference a TABLES1 entry. (Real > 0 or Blank) |

TYPSTRN |

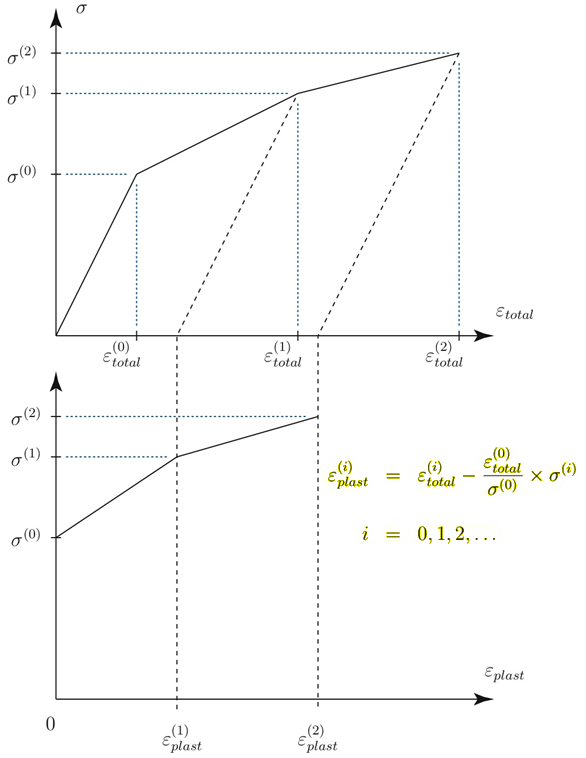

Specifies the type of strain used on the x-axis of the table pointed to by TID. The strain type is selected by one of the following values. See comment 5. 0 - total strain is used on the x-axis. 1 - plastic strain is used on the x-axis. Default = 0 (Integer 0 or 1) |

| 1. | For nonlinear elastic material, the stress-strain data given in the TABLES1 entry will be used to determine the stress for a given value of strain. The values H, YF, HR, and LIMIT1 will not be used in this case. Nonlinear elastic material is only available in NLGEOM subcases. |

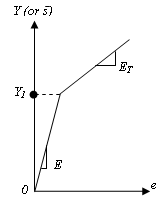

| 2. | For elastoplastic materials, the elastic stress-strain matrix is computed from a MAT1 entry, and the isotropic plasticity theory is used to perform the plastic analysis. In this case, either the table identification TID or the work hardening slope H may be specified, but not both. If the TID is omitted, the work hardening slope H must be specified, unless the material is perfectly plastic. The plasticity modulus (H) is related to the tangential modulus (ET ) by: |

where, E is the elastic modulus and ![]() is the slope of the uniaxial stress-strain curve in the plastic region.

is the slope of the uniaxial stress-strain curve in the plastic region.

Stress-strain curve definition when H is specified in field 5.

| 3. | If TID is given, TABLES1 entries (Xi,Yi) of stress-strain data ( |

If TYPE = "PLASTIC", the curve must be defined in the first quadrant. The data points must be in ascending order. If the table is defined in terms of total strain (TYPSTRN = 0), the first point must be at the origin (X1 = 0, Y1 = 0) and the second point (X2, Y2) must be at the initial yield point (Y1) specified on the MATS1 entry. The slope of the line joining the origin to the yield stress must be equal to the value of E. If the table is defined in terms of plastic strain (TYPSTRN = 1), the first point (X1, Y1), corresponding to yield point (Y1), must be at X1=0. TID may reference a TABLEST entry. In this case, the above rules apply to all TABLES1 tables pointed to by TABLEST.

If TYPE = “NLELAST”, the full stress-strain curve may be defined in the first and third quadrants to accommodate different uniaxial compression data. If the curve is defined only in the first quadrant, then the curve must start at the origin (X1 = 0.0, Y1 = 0.0).

For analysis where small deformations are assumed, there should be little or no difference between the true stress-strain curve and the engineering stress-strain curve, so either of them may be used in the TABLES1 definition. For analyses where small deformations are not assumed, the true stress-strain curve should be used.

If the deformations go past the values defined in the table, the curve is extrapolated linearly.

| 4. | Kinematic hardening and Mixed hardening are supported only for solids. |

| 5. | The conversion of the relation stress vs. total strain (TYPSTRN=0) into stress vs. plastic strain (TYPSTRN=1) is illustrated below. This is clearly different than simply shifting the entire table along the epsilon-axis. |

| 6. | The temperature-dependence of the MATS1 material is defined by referencing a TABLEST entry via the TID field. |

| 7. | Large strain elasto-plasticity can be activated using MATS1 (TYPE=PLASTIC) in conjunction with PARAM, LGDISP, 1. |

| 8. | Linear Buckling Analysis and Preloaded Analysis are not supported with models containing nonlinear (MATS1) material entries. However, PARAM,PRESUBNL,YES can be used to force OptiStruct to run in such models. Linear Buckling Analysis or Preloaded Analysis is not recommended in models with nonlinear materials or in large displacement nonlinear analysis. It is your responsibility to interpret the results with caution. |

| 9. | MATS1 is not supported in conjunction with second order shell elements (CTRIA6 and CQUAD8). MATS1 is also currently not supported with 1D elements. |

See Also: