MATX33 |

|

|

|

|

|

MATX33 |

|

|

|

|

Bulk Data Entry

MATX33 – Material Property Extension for Visco-Elastic Plastic Foam Material for Geometric Nonlinear Analysis

Description

Defines additional material properties for visco-elastic plastic foam material for geometric nonlinear analysis.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

MATX33 |

MID |

KA |

TID |

FSCALE |

P0 |

PHI |

EPSV0 |

|

|

|

A |

B |

C |

E1 |

E2 |

ET |

ETAC |

ETAS |

|

|

Field |

Contents |

MID |

Material ID of the associated MAT1. See comment 1. No default (Integer > 0) |

KA |

Analysis type flag. Default = ELAST (Character = ELAST or VISCO) ELAST: skeletal behavior before yield is elastic. VISCO: skeletal behavior before yield is visco-elastic. |

TID |

Identification number of TABLES1 entry that defines the yield stress vs. volumetric strain curve. If defined, σy vs. No default (Integer > 0) |

FSCALE |

Scale factor for stress in yield curve. Default = 1.0 (Real) |

P0 |

Initial air pressure. See comment 4. Default = 0.0 (Real) |

PHI |

Ratio of foam to polymer density. Default = 0.0 (Real) |

EPSV0 |

Initial volumetric strain. Default = 0.0 (Real) |

A |

Yield parameter. Default = 0.0 (Real) |

B |

Yield parameter. Default = 1.0 (Real) |

C |

Yield parameter. Default = 1.0 (Real) |

E1 |

Coefficient for Young's modulus update. No default (Real) |

E2 |

Coefficient for Young's modulus update. No default (Real) |

ET |

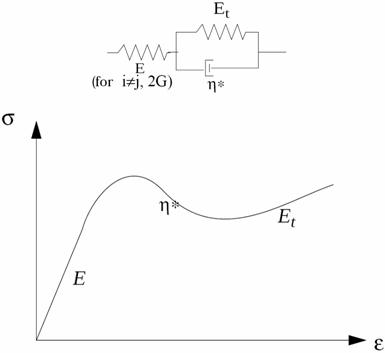

Tangent modulus. No default (Real > 0) |

ETAC |

Viscosity coefficient in pure compression. Default = 1.0 (Real > 0) |

ETAS |

Viscosity coefficient in pure shear. Default = 1.0 (Real > 0) |

| 1. | The material identification number must be that of an existing MAT1 bulk data entry. Only one MATXi material extension can be associated with a particular MAT1. |

| 2. | MATX33 is only applied in geometric nonlinear analysis subcases which are defined by ANALYSIS = EXPDYN. It is ignored for all other subcases. |

| 3. | This material can be used only with solid elements, typically used to model low density, closed cell polyurethane foams such as impact limiters. |

| 4. | The air pressure is computed as: |

Pair = P0 * ![]() / (1+

/ (1+ ![]() - Φ), with

- Φ), with ![]() =

= ![]() 0 + V/V0 - 1

0 + V/V0 - 1

where, ![]() is the volumetric strain, Φ is the porosity, P0 is the initial air pressure,

is the volumetric strain, Φ is the porosity, P0 is the initial air pressure, ![]() 0 is the initial volumetric strain. The volumetric strain

0 is the initial volumetric strain. The volumetric strain ![]() < 0 in compression.

< 0 in compression.

| 5. | If TID is blank or zero, then |

σy = A + B(1+ Cγ), with ![]() = V/V0 - 1 = ρ/ρ0 - 1 = -μ/(1+μ)

= V/V0 - 1 = ρ/ρ0 - 1 = -μ/(1+μ)

| 6. | The Young’s modulus used in the calculation is: |

E = max(E, E1![]() + E2)

+ E2)

This material assumes NU = 0 no matter what is defined on the corresponding MAT1. Hence, G = 0.5 * E.

| 7. | This card is represented as an extension to a MAT1 material in HyperMesh. |

See Also: