MATX36 |

|

|

|

|

|

MATX36 |

|

|

|

|

Bulk Data Entry

MATX36 – Material Property Extension for Piece-wise Linear Elastic-plastic Material for Geometric Nonlinear Analysis

Description

Defines additional material properties for piece-wise linear elastic-plastic material for geometric nonlinear analysis.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

MATX36 |

MID |

EPSMAX |

EPST1 |

EPST2 |

EPSF |

FSMOOTH |

FCUT |

ICH |

|

|

TPID |

PSCA |

|

|

|

|

|

|

|

|

TID1 |

FSCA1 |

EPSR1 |

|

|

|

|

|

|

|

... |

... |

... |

|

|

|

|

|

|

|

TIDi |

FSCAi |

EPSRi |

|

|

|

|

|

|

|

Field |

Contents |

MID |

Material identifier of the associated MAT1. See comment 1. No default (Integer > 0) |

EPSMAX |

Failure plastic strain εmax Default = 1030 (Real > 0) |

EPST1 |

Maximum tensile failure strain. See comment 5. Default = 1030 (Real > 0) |

EPST2 |

Maximum tensile failure damage. See comment 6. Default = 2.0*1030 (Real > 0) |

EPSF |

Tensile strain for element deletion. Default = 3.0*1030 (Real > 0) |

FSMOOTH |

Strain rate smoothing flag. Default = OFF (ON or OFF) |

FCUT |

Cutoff frequency for strain rate filtering. Only for shell and solid elements. Default = 1030 (Real > 0) |

ICH |

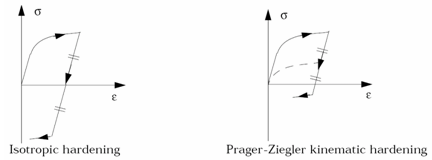

Hardening coefficient. Default = 0.0 (Real > 0) 0.0 - The hardening is a full isotropic model. 1.0 - Hardening uses the kinematic Prager-Ziegler model. Between 0.0 and 1.0 - Hardening is interpolated between the two models. |

TPID |

Identification number of a TABLES1 that defines pressure dependent yield stress function. No default (Integer > 0) |

PSCA |

Scale factor for stress in pressure dependent function. Default = 1.0 (Real) |

TIDi |

Identification number of a TABLES1 that defines the yield stress vs. plastic strain function corresponding to EPSRi. Separate functions must be defined for different strain rates. No default (Integer > 0) |

FSCAi |

Scale factor for TIDi. Default = 1.0 (Real) |

EPSRi |

Strain rate. Strain rate values must be given strictly in ascending order. (Real) |

| 1. | The material identification number must be that of an existing MAT1 bulk data entry. Only one MATXi material extension can be associated with a particular MAT1. |

| 2. | MATX36 is only applied in geometric nonlinear analysis subcases which are defined by ANALYSIS = EXPDYN. It is ignored for all other subcases. |

| 3. | The first point of yield stress functions (plastic strain vs. stress) should have a plastic strain value of zero. If the last point of the first (static) function equals 0 in stress, the default value of EPSMAX is set to the value of the corresponding plastic strain. |

| 4. | When the plastic strain reaches EPSMAX, the element is deleted. |

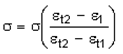

| 5. | If the first principal strain ε1 reaches εt1 = EPST1, the stress σ is reduced by: |

with εt2 = EPST2.

| 6. | If the first principal strain ε1 reaches εt2 = EPST2, the stress is reduced to 0 (but the element is not deleted). |

| 7. | If the first principal strain ε1 reaches εf = EPSF, the element is deleted. |

| 8. | Strain rate filtering is used to smooth strain rates. The input FCUT is available only for shell and solid elements. |

| 9. | Hardening is defined by ICH. |

| 10. | The kinematic hardening model is not available with global formulation (NIP = 0 on PSHELX), that is hardening is fully isotropic. |

| 11. | In case of kinematic hardening and strain rate dependency, the yield stress depends on the strain rate. |

| 12. | TPID is used to distinguish the behavior in tension and compression for certain materials (that is pressure dependent yield). This is available for both shell and solid elements. The effective yield stress is then obtained by multiplying the nominal yield stress by the yield factor PSCA corresponding to the actual pressure. |

| 13. | The first function TID1 is used for strain rate values from 0 to the corresponding strain rate EPSR1. However, the last function used in the model does not extend to the maximum strain rate; for higher strain rates, a linear extrapolation will be applied. Hence, if |

| 14. | Strain rate values must be given strictly in ascending order. Separate functions must be defined for different strain rates. |

| 15. | At least one strain rate is needed under which the yield stress vs. plastic strain function is defined. |

| 16. | This card is represented as a material in HyperMesh. |

See Also: