MATX44 |

|

|

|

|

|

MATX44 |

|

|

|

|

Bulk Data Entry

MATX44 – Material Property Extension for Cowper-Symonds Elastic-plastic Material for Geometric Nonlinear Analysis

Description

Defines additional material properties for Cowper-Symonds elastic-plastic material for geometric nonlinear analysis.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

MATX44 |

MID |

A |

B |

N |

ICH |

SIGMAX |

C |

P |

|

|

ICC |

FSMOOTH |

FCUT |

EPSMAX |

EPST1 |

EPST2 |

|

|

|

|

Field |

Contents |

MID |

Material ID of the associated MAT1. No default (Integer > 0) |

A |

Plasticity yield stress. (Real > 0) |

B |

Plasticity hardening parameter. (Real > 0) |

N |

Plasticity hardening exponent. Default = 1.0 (Real) |

ICH |

Hardening coefficient. 0.0: The hardening is a full isotropic model. Default = 0.0 (Real > 0) |

SIGMAX |

Maximum plastic stress σmax0 Default = 1030 (Real > 0) |

C |

Strain rate coefficient. Default = 0.0 (Real) |

P |

Strain rate exponent. Default = 1.0 (Real) |

ICC |

Strain rate dependency of σmax flag. See comment 5. Default = ON (ON or OFF) |

FSMOOTH |

Strain rate smoothing flag. Default = OFF (ON or OFF) |

FCUT |

Cutoff frequency for strain rate filtering. Default = 1030 (Real > 0) |

EPSMAX |

Failure plastic strain. Default = 1030 (Real > 0) |

EPST1 |

Tensile rupture strain 1. Default = 1030 (Real > 0) |

EPST2 |

Tensile rupture strain 2. Default = 2.0 * 1030 (Real > 0) |

| 1. | The material identification number must be that of an existing MAT1 bulk data entry. Only one MATXi material extension can be associated with a particular MAT1. |

| 2. | MATX44 is only applied in geometric nonlinear analysis subcases which are defined by ANALYSIS = EXPDYN. It is ignored for all other subcases. |

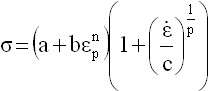

| 3. | The Cowper-Symonds models an elastic-plastic material, only for solids and shells. The basic principle is the same as the standard Johnson-Cook model; the only difference between the two lies in the expression for strain rate effect on flow stress |

with εp being plastic strain, and ![]() being the strain rate.

being the strain rate.

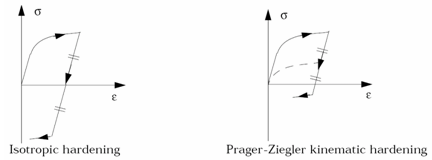

| 4. | Hardening is defined by ICH. |

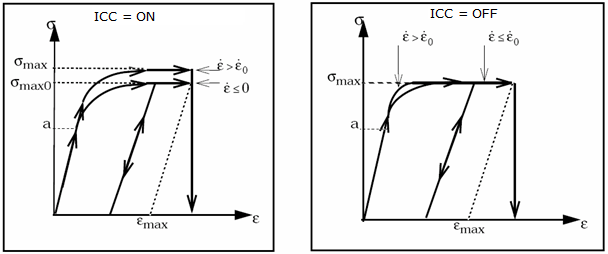

| 5. | ICC controls the strain rate effect. |

| 6. | No strain rate effects are considered in rod elements. |

| 7. | Strain rate filtering is used to smooth strain rates. The input FCUT is available only for shell and solid elements. |

| 8. | When the plastic strain reaches EPSMAX, the element is deleted. |

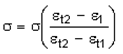

| 9. | If the first principal strain ε1 reaches εt1 = EPST1, the stress σ is reduced by: |

with εt2 = EPST2.

| 10. | If the first principal strain ε1 reaches εt2 = EPST2, the stress is reduced to 0 (but the element is not deleted). |

| 11. | If the first principal strain ε1 reaches εf = EPSF, the element is deleted. |

| 12. | This card is represented as an extension to a MAT1 material in HyperMesh. |

See Also: