PCNTX24 |

|

|

|

|

|

PCNTX24 |

|

|

|

|

Bulk Data Entry

PCNTX24 – Extended CONTACT Property type 24 for Geometric Nonlinear Analysis

Description

Defines properties type 24 of a CONTACT interface for geometric nonlinear analysis.

Format

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

(8) |

(9) |

(10) |

PCNTX24 |

PID |

|

|

|

|

|

|

|

|

|

ISTF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GAPMAXs |

GAPMAXm |

|

|

|

STMIN |

STMAX |

IGAP0 |

IPEN0 |

IPENMAX |

IPENMIN |

|

|

|

|

STFAC |

FRIC |

|

TSTART |

TEND |

|

|

|

|

|

IBC |

|

|

INACTI |

VISS |

|

|

|

|

|

IFRIC |

IFILT |

FFAC |

|

SENSID |

|

|

|

|

|

FRICDAT |

C1 |

C2 |

C3 |

C4 |

C5 |

C6 |

|

|

|

Field |

Contents |

PID |

Property identification number of the corresponding PCONT entry. No default (Integer > 0) |

ISTF |

Stiffness definition flag (See comment 5). Default as defined by CONTPRM (Integer = 0, …, 5) 0 - The stiffness is computed according to the master side characteristics. |

GAPMAXs |

Slave maximum gaps. (Real) |

GAPMAXm |

Master maximum gaps. (Real) |

STMIN |

Minimum stiffness (Only with ISTF > 1). Default as defined by CONTPRM (Real > 0) |

STMAX |

Maximum stiffness (Only with ISTF > 1). Default as defined by CONTPRM (Real > 0) |

IGAP0 |

Gap modification flag for slave shell nodes on the free edges. (Integer) 0 - No change 1 - Set gap to zero for the slave shell nodes |

IPEN0 |

Initial penetration detection flag (Integer) 0 - default method. Excludes the initial auto-impacts in the same part (shell and solid elements only). IPEN0 = 1 takes into account the initial auto-impacts in the same part, but in some complex situations, wrong initial penetrations might be given. 1 - method 1 (including auto-impact in each part) |

IPENMAX |

Maximum initial penetration: Penetration higher than this value will not be taken into account. (Real) |

IPENMIN |

Minimum initial penetration: Penetration higher than this value will be taken into account. (Real) |

STFAC |

Interface stiffness scale factor. Default as defined by CONTPRM (Real > 0) |

FRIC |

Coulomb friction. Default as defined by CONTPRM (Real > 0) |

TSTART |

Start time Default = 0.0 (Real > 0) |

TEND |

Time for temporary deactivation. Default = 1030 (Real > 0) |

IBC |

Flag for deactivation of boundary conditions at impact applied to the slave grid set. Default as defined by CONTPRM (Character = X, Y, Z, XY, XZ, YZ, or XYZ) |

INACTI |

Handling of initial penetrations flag. Default as defined by CONTPRM (Integer = 0, 1, -1, or 5) 0 - only tiny initial penetrations (1.0e-08) will be taken into account. Ignores the initial penetrations, but the contacts are not deleted, new contact will be well detected once the penetrations are disappeared gap0 = gap - P0, where P0 is the initial penetration |

VISS |

Critical damping coefficient on interface stiffness. Default as defined by CONTPRM (Real > 0) |

IFRIC |

Friction formulation flag (See comment 8). Default as defined by CONTPRM (Character = COUL, GEN, DARM, or REN) COUL - Static Coulomb friction law. |

IFILT |

Friction filtering flag (See comment 9). Default as defined by CONTPRM (Character = NO, SIMP, PER, or CUTF) NO - No filter is used. |

FFAC |

Friction filtering factor. Default as defined by CONTPRM |

SENSID |

Sensor identifier to Activate/Deactivate the interface (See comment 12) No default (Integer) If a sensor identifier is defined, the activation/deactivation of interface is based on the sensor and not on Tstart or Tstop. |

FRICDAT |

Indicates that additional information for IFRIC will follow. Only available when IFRIC = GEN, DARM or REN. |

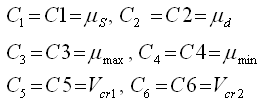

C1, C2, C3, C4, C5, C6 |

Coefficients to define variable friction coefficient in IFRIC = GEN, DARM, or REN. Default as defined by CONTPRM (Real > 0) |

| 1. | The property identification number must be that of an existing PCONT bulk data entry. Only one PCNTX24 property extension can be associated with a particular PCONT. |

| 2. | PCNTX24 is only supported for geometric nonlinear explicit dynamic analysis subcase defined by ANALYSIS = EXPDYN. It is ignored for all other subcases. |

| 3. | If FRIC is not explicitly defined on the PCONTX/PCNTX# entries, the MU1 value on the CONTACT or PCONT entry is used for FRIC in the /INTER entries for Geometric Nonlinear Analysis. Otherwise, FRIC on PCONTX/PCNTX# overwrites the MU1 value on CONTACT/PCONT. |

| 4. | In implicit analysis, different contact formulations are used for contact where slave and master set do not overlap and where they overlap (self-contact). |

In the case of self-contact, the gap cannot be zero and a constant gap is used. For small initial gaps, the convergence will be more stable and faster if GAP is larger than the initial gap.

In implicit analysis, sometimes a stiffness with scaling factor reduction (for example, STFAC = 0.01) or reduction in impacted thickness (if rigid one) might reduce unbalanced forces and improve convergence, particularly in shell structures under bending where the effective stiffness is much lower than membrane stiffness; but it should be noted that too low of a value could also lead to divergence.

| 5. | If ISTF ≠ 1, the interface stiffness K is computed from the master segment stiffness Km and/or the slave segment stiffness Ks. |

The master stiffness is computed from Km = STFAC * B * S * S/V for solids, Km = 0.5 * STFAC * E * t for shells.

The slave stiffness is an equivalent nodal stiffness computed as Ks = STFAC * B * V-3 for solids, Ks = 0.5 * STFAC * E * t for shells.

In these equations, B is the Bulk Modulus, S is the segment area, and V is the volume of a solid. There is no limitation to the value of stiffness factor (but a value larger than 1.0 can reduce the initial time step).

The interface stiffness is K = max (STMIN, min (STMAX, K1)) with:

| • | ISTF = 0, K1 = Km |

| • | ISTF = 2, K1 = 0.5 * (Km + Ks) |

| • | ISTF = 3, K1 = max (Km, Ks) |

| • | ISTF = 4, K1 = min (Km, Ks) |

| • | ISTF = 5, K1 = Km * Ks / (Km + Ks) |

| 6. | The gap is computed automatically (similar with IGAP = VAR on PCNTX7) for each impact as gs + gm; |

with:

| • | gm - master element gap, with: |

gm = t/2, t: thickness of the master element for shell elements.

gm = 0 for solid elements.

| • | gs - slave node gap: |

gs = 0 if the slave node is not connected to any element or is only connected to solid or spring elements.

gs = t/2, t - largest thickness of the shell elements connected to the slave node.

gs = 1/2√S for truss and beam elements, with S being the cross section of the element.

gm and gs are limited separately by GAPMAXm and GAPMAXs before the gap computation.

| 7. | The coefficients C1 - C6 are used to define a variable friction coefficient |

| 8. | IFRIC defines the friction model. |

IFRIC = COUL – Coulomb friction with FT < FRIC * FN.

For IFRIC > 0 the friction coefficient is set by a function (![]() )

)

where, p is the pressure of the normal force on the master segment and V is the tangential velocity of the slave node.

The following formulations are available:

| • | IFRIC = GEN - Generalized viscous friction law |

![]() FRIC + C1 * p + C2 * V + C3 * p * v + C4 * p2 + C5 * v2

FRIC + C1 * p + C2 * V + C3 * p * v + C4 * p2 + C5 * v2

| • | IFRIC = DARM - Darmstad law |

![]() = C1 * e(C2V) * p2 + C3 * e(C4V) * p + C5 * e(C6V)

= C1 * e(C2V) * p2 + C3 * e(C4V) * p + C5 * e(C6V)

| • | IFRIC = REN - Renard law |

|

0 < V < C5 |

|

C5 < V < C6 |

|

C6 < V |

where:

| • | The first critical velocity Vcr1 must not be 0 (C5 ≠ 0). It also must be lower than the second critical velocity Vcr2 (C5 < C6). |

| • | The static friction coefficient C1 and the dynamic friction coefficient C2, must be lower than or equal to the maximum friction C3 (C1 < C3 and C2 < C3). |

| • | The minimum friction coefficient C4, must be lower than or equal to the static friction coefficient C1 and the dynamic friction coefficient C2 (C4 < C1 and C4 < C2). |

| 9. | IFILT defines the method for computing the friction filtering coefficient. If IFILT ≠ NO, the tangential friction forces are smoothed using a filter: |

FT = α * F'T + (1 - α) * F'T-1

where,

FT is the tangential force

F'T is the tangential force at time t

F'T-1 is the tangential force at time t-1

α is the filtering coefficient

IFILT = SIMP – α = FFAC

IFILT = PER – α = 2![]() dt/FFAC, where dt/T = FFAC, T is the filtering period

dt/FFAC, where dt/T = FFAC, T is the filtering period

IFILT = CUTF – α = 2![]() * FFAC * dt, where FFAC is the cutting frequency

* FFAC * dt, where FFAC is the cutting frequency

| 10. | IFORM selects two types of contact friction penalty formulation. |

The viscous (total) formulation (IFORM = VISC) computes an adhesive force as:

Fadh = VISF * √(2KM) * VT

FT = min (µFN, Fadh)

The stiffness (incremental) formulation (IFORM = STIFF) computes an adhesive force as:

Fadh = FTold + ΔFT

ΔFT = K * VT * dt

FTnew = min (µFN, Fadh)

| 11. | When SENSID is defined for activation/deactivation of the interface, TSTART and TSTOP are not taken into account. |

| 12. | When the contact type is the symmetric surface to surface, the output normal contact forces in TH file are correctly calculated if the two surfaces are well separated. |

| 13. | For implicit test: Interface type24 is now only available with SMP. The default of ISTF will be set to 4. The default INACTI will be set to -1. |

| 14. | This card is represented as an extension to a PCONT property in HyperMesh. |

See Also: