Universal Joint |

|

|

|

|

|

Universal Joint |

|

|

|

|

This section describes the Universal joint entity of MotionView and shows the various usage, creation, and editing methods.

A Universal joint is a two degree-of-freedom kinematic pair used in mechanisms. It is functionally identical to, and also referred to as a Hooke joint. The only difference between these two joints is the way that the joint is defined. Universal joints provide two rotational functions used in applications such as:

| • | Propeller shafts/drive shafts |

| • | Steering columns |

| • | Any shaft assembly where the connecting shafts are not aligned along a line |

Universal joint construction

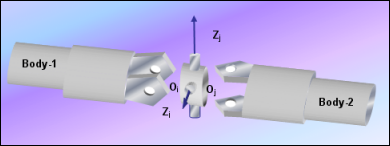

The Universal joint is represented using Markers when exported to an MBD Solver. The representation can be visualized as shown in the two figures below:

Universal joint - Shaft orientation |

Universal joint - Crosspin orientation |

The bodies that are constrained by an Inline joint are represented using two markers: Marker I and Marker J. Marker I belongs to Body 1 and Marker J belongs to Body 2. The constraints are applied on Marker I with respect to Marker J. Both of the markers will have a common point of origin, the same as the joint’s Origin point. The Z axes of Marker I and Marker J are always perpendicular to each other by definition. Since a Universal joint connects two intersecting but non-aligned shafts/bodies, the joint needs two axes to complete the definition: one for each shaft/body. MotionView allows two different schemes for orienting a Universal joint, namely Shaft and Crosspin. The X axis of the respective markers can be oriented using the Shaft scheme and Y axis can be oriented using the Crosspin scheme. Shaft orientation can be interpreted as orienting the yoke of the joint and Crosspin orientation as the spider of the joint.

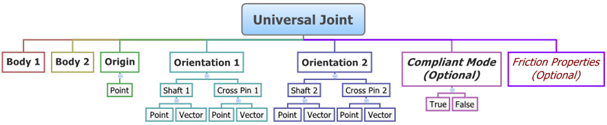

The topological information required to define an Universal joint is shown in the figure below:

The data members of the Universal joint can be classified into the following members:

An Universal joint needs the following:

| • | Body 1 and Body 2 - Specify two bodies between which the joint is to be created. |

| • | Origin - Specify Point, which defines the location of the joint. |

| • | Orientation 1 - The orientation of the axis of rotation of Body 1 specified using a Point or Vector and either a Shaft or Crosspin scheme. |

| • | Orientation 2 - The orientation of the axis of rotation of Body 2 specified using a Point or Vector and either a Shaft or Crosspin scheme. |

| • | Compliant Mode (Optional) - If the Allow Compliance option is selected while adding the joint to a model, the joint's compliance state can be toggled between Compliant and Non-Compliant. |

| • | Friction Properties (Optional) - can also be assigned (see Properties below). |

The joint can be modeled as a Single entity or as a Pair entity.

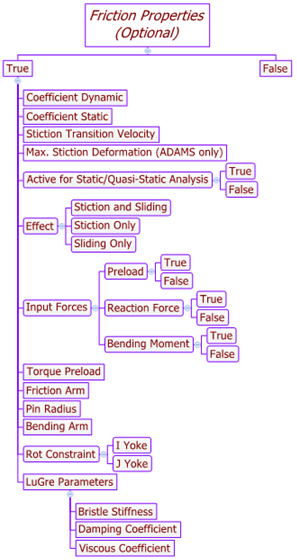

Optional Friction properties can also be specified for the joint:

Activating the Use Friction option on the Friction Properties tab will display the following options in the panel:

Coefficient Dynamic |

|

||||||

Coefficient Static |

|

||||||

Stiction Transition Velocity |

|

||||||

Max. Stiction Deformation (Adams only) |

|

||||||

Active for Static/Quasi-Static Analysis |

True/False |

||||||

Effect |

|

||||||

Input Forces |

|

||||||

Torque Preload |

|

||||||

Friction Arm |

|

||||||

Pin Radius |

|

||||||

Bending Arm |

|

||||||

Rot Constraint |

|

||||||

LuGre Parameters |

|

To learn how to add a Universal joint to a model, please see the Joints topic.

Joints Panel (Universal Joint) – Connectivity Tab - Single Entity - Shaft Orientation

Joints Panel (Universal Joint) – Connectivity Tab - Pair Entity - Crosspin Orientation

The figure below shows the geometries that are oriented using the two different schemes:

Universal joint using Shaft and Crosspin

OR

Joints panel - Friction Properties tab Checking the Use Friction option displays a set of input fields which you need to specify as needed by the friction model of the solver. In addition, the LuGre Parameters tab also appears if the SolverMode is set to MotionSolve.

Joints panel - LuGre Parameters tab For additional details on the various fields in the Friction Properties and LuGre Parameters tab, please refer to the Joints Panel – Friction Properties Tab and Joints Panel - LuGre Parameters Tab topics. Based on the joint selection, the relevant fields will be displayed in the Friction Properties tab. These fields are populated by default values as shown above. You can click the Restore Default Values button in the LuGre Parameters tab in order to populate default LuGre parameters. Note - The same steps as shown above can also be used to define Pair Cylindrical joint entities. When defining a Pair Cylindrical joint use pair entities for Body 1, Body 2, Origin, etc. |

The Project Browser will filter the entities and display only the joints in the model.

The corresponding panel is automatically displayed.

Joints panel - Connectivity tab - joint type drop-down menu |

The model containing the Universal joint can be saved in MDL format from MotionView and exported in the MotionSolve XML format.

The Universal joint can be of the following types:

These four types of entities can be added to the model using MDL Statements shown below:

To learn how to create a complete model using MDL Statements please refer to tutorial MV-1060: Introduction to MDL. |

The Universal joint when exported to the MotionSolve XML format is defined as a Constraint_Joint statement. Syntax: <Constraint_Joint id = "integer" label = "Name of Joint" type = "JOINT TYPE" i_marker_id = "integer" j_marker_id = "integer" /> In case of the Universal joint the model statement will be as shown below: <Constraint_Joint id = "301001" label = "Universal Joint" type = "UNIVERSAL" i_marker_id = "30103050" j_marker_id = "30101050" /> In the above XML Model statement the i_marker_id and j_marker_id represent the I and J markers of the Joint which belong to Body 1 and Body 2 respectively. To understand the complete syntax of the Constraint_Joint XML model statement, please refer to the MotionSolve Reference Guide Page for Constraint_Joint. |

In MotionView, the Tcl command layer can be used to add any MDL entities to the model. There are two Tcl commands that can be used to add an entity:

Syntax: mdlmodel_handle InterpretEntity new_handle keyword varname label In case of the Universal joint the statement will look as shown below: mdlmodel_handle InterpretEntity UJt_handle UJoint j_uj "\"U Joint\"" b_1 B_Ground p_ori "SHAFT" "POINT" p_ori1 "CROSSPIN" "VECTOR" v_1 "ALLOW_COMPLIANCE"; |

Syntax: mdlmodel_handle InterpretSet keyword tokens Example: mdlmodel_handle InterpretSet SetJointFriction j_uj true mu_static mu_dynamic use_static transition_vel max_deformation effect preload_input reaction_force_input bending_moment_input torsional_moment_input f_preload reaction_arm initial_overlap overlap_delta rot_constraint t_preload pin_radius friction_arm bending_reaction_arm ball_radius

mdlmodel_handle InterpretSet SetJointFrictionLugre j_uj bristle_stiffness damping_effects viscous_effects |

The InterpretEntity command is used to add entities to the model and the InterpretSet command is used to set the entity properties. So in the case of the Universal joint, the properties that can be set are the joint friction. Extended definitions for InterpretEntity and InterpretSet can be found in the HyperWorks Desktop Reference Guide.

Note - When using the InterpretEntity and InterpretSet commands, it is important to also use the Evaluate command in order for the changes to take effect immediately.

To learn how to create a complete model using Tcl commands, please refer to tutorial MV-1040: Model Building Using Tcl.

The example file below shows a Universal joint connecting two bodies:

*BeginMDL( the_model, "Model", "12.0.110.26" ) *StandardInclude(FILE) *PointPair( p_sjorigin, "Pair joint origin" ) *Point( p_b1cg, "Body 1 CG" ) *Point( p_b2cg, "Body 2 CG" ) *Point( p_jor, "Joint origin" ) *Body( b_1, "Body 1", p_b1cg, , , , ) *Body( b_2, "Body 2", p_b2cg, , , , ) //Universal joint - single using CROSSPIN orientation *UJoint( j_uj, "Universal Joint", b_1, b_2, p_jor, CROSSPIN, VECTOR, V_Global_Z, CROSSPIN, VECTOR, V_Global_Y ) //Universal joint - pair using SHAFT orientation *UJointPair( j_pujoint, "Universal Joint Pair", b_a, b_b, p_sjorigin, SHAFT, POINT, p_ori1, SHAFT, POINT, p_ori2 ) *PointPair( p_ori1, "Orient point 1" ) *PointPair( p_ori2, "Orient point 2" ) *BodyPair( b_a, "Body A", p_bodyA_cg, , , , b_a.cm ) *BodyPair( b_b, "Body B", p_bodyB_cg, , , , ) *PointPair( p_bodyA_cg, "Body A CG" ) *PointPair( p_bodyB_cg, "Body B CG" ) *VectorPair( v_ori1, "Orient vector 1" ) *VectorPair( v_ori2, "Orient vector 2" ) *SetPoint( p_ori1, LEFT, -100, -50, -25 ) *SetPoint( p_sjorigin, LEFT, , -50 ) *SetPoint( p_ori2, LEFT, 100, -50, 0 ) *SetPoint( p_bodyA_cg, LEFT, -50, -50, -12.5 ) *SetPoint( p_bodyB_cg, LEFT, 50, -50 ) *Set( b_a.usecm, true ) *Set( b_b.usecm, true ) *SetVector( v_ori1, LEFT, -0.2425, 0, 0.9701 ) *SetVector( v_ori2, LEFT, 0, 1, 0 ) *SetPoint( p_b1cg, -50, , -12.5 ) *SetPoint( p_b2cg, 50 ) *Set( b_1.usecm, true ) *Set( b_2.usecm, true ) //Setting joint friction using SetJointFriction - Single *SetJointFriction( j_uj, true, 0.32, 0.26, ACTIVE_STATIC, 0.11, , STICTION_ONLY, PRELOAD, REACTION_FORCE, BENDING_MOMENT, , , , , , I_YOKE, 1000, 5, 10, 3 ) //Setting joint friction using SetJointFriction - Symmetric Pair *SetJointFriction( j_pujoint, LEFT, true, , , ACTIVE_STATIC, , , , PRELOAD, REACTION_FORCE, BENDING_MOMENT, , , , , , I_YOKE, 1000, 5, 10, 25, ) //Setting joint friction using SetJointFriction - Asymmetric Pair *SetJointFriction( j_pujoint, , true, , , ACTIVE_STATIC, , , , PRELOAD, REACTION_FORCE, BENDING_MOMENT, , , , , , I_YOKE, 1000, 5, 10, 25, , true, 0.3, 0.25, ACTIVE_STATIC, 0.1, 0.01, STICTION_AND_SLIDING, PRELOAD, REACTION_FORCE, BENDING_MOMENT, TORSIONAL_MOMENT, 0.0, 1.0, 1000.0, CONSTANT, J_YOKE, 1500, 4, 8, 30, 1.0 ) //Setting joint friction LuGre parameters using SetJointFrictionLugre - Pair *SetJointFrictionLugre( j_pujoint, 100.0, 0.316, 0.0004 , 100.0, 0.316, 0.0004 ) *EndMDL() |

See Also:

*UJoint (MDL Model Statement)

*UJointPair (MDL Model Statement)

Constraint_Joint (XML Command)

InterpretEntity (Tcl Command)

InterpretSet (Tcl Command)